Rapid partition wall of water storage building and pipe culvert

A technology for partition walls and structures, applied in buildings, waterway systems, water supply devices, etc., can solve problems such as many safety hazards, limited space, and large impact, and achieve the effects of avoiding limited space, large economic benefits, and reducing production stoppages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The content of the present invention is further described below through specific examples.

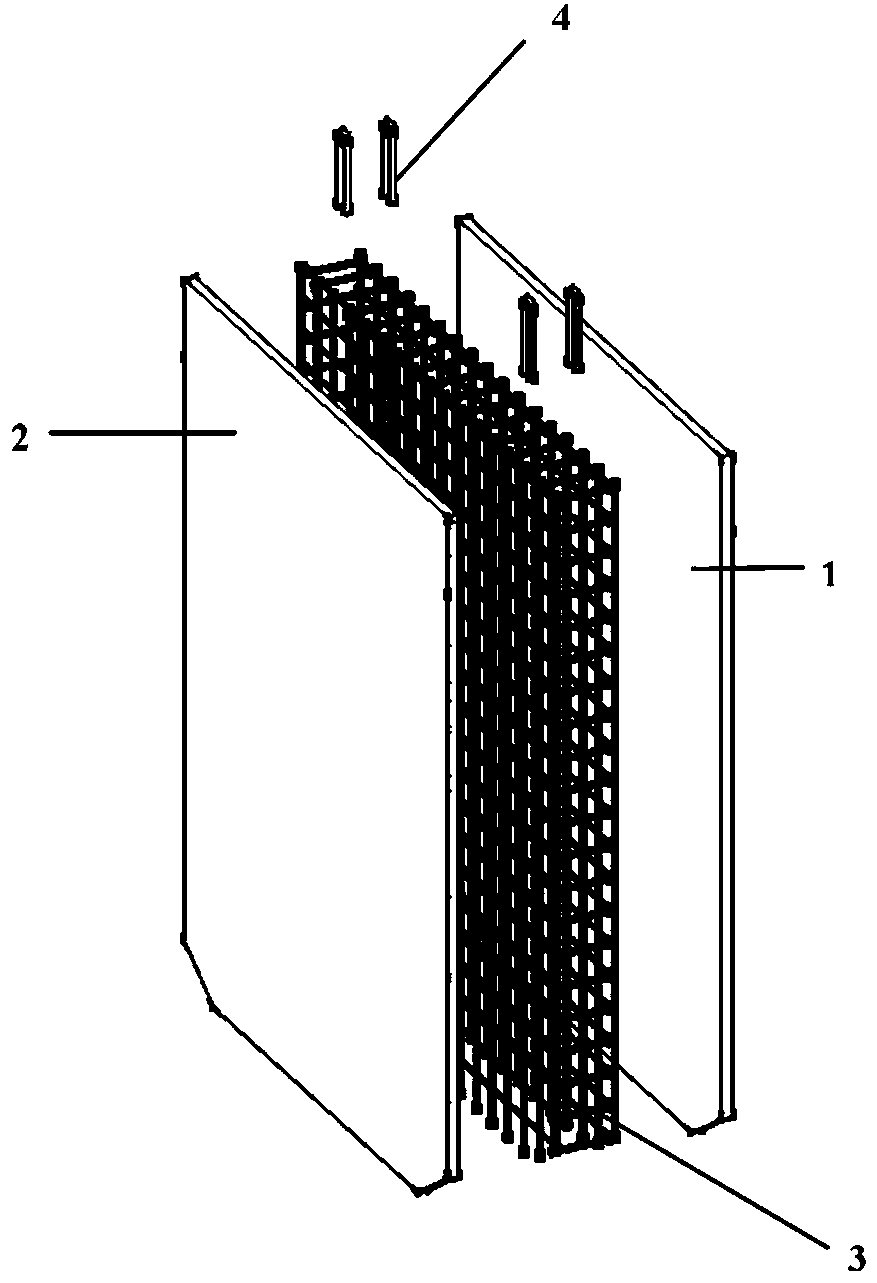

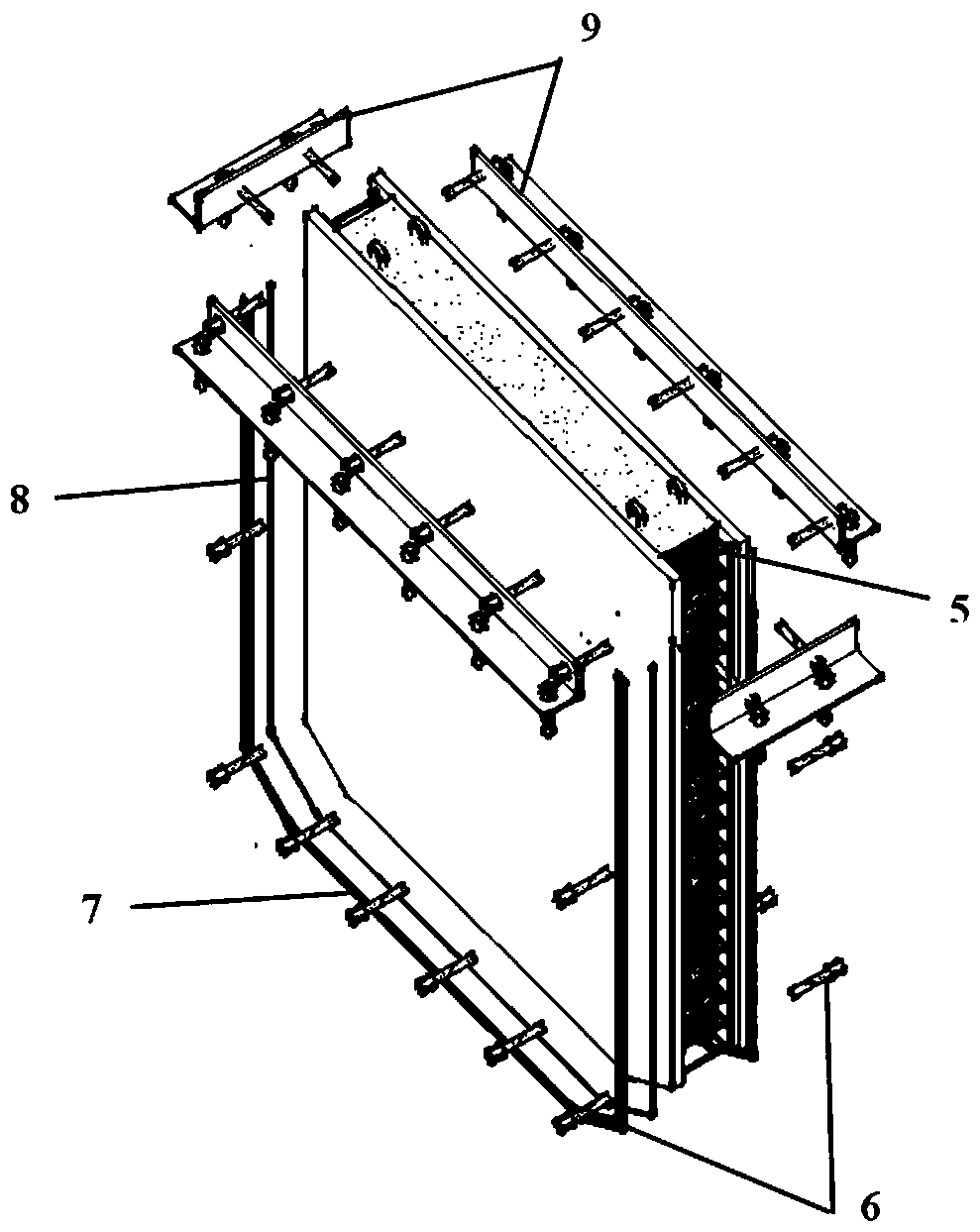

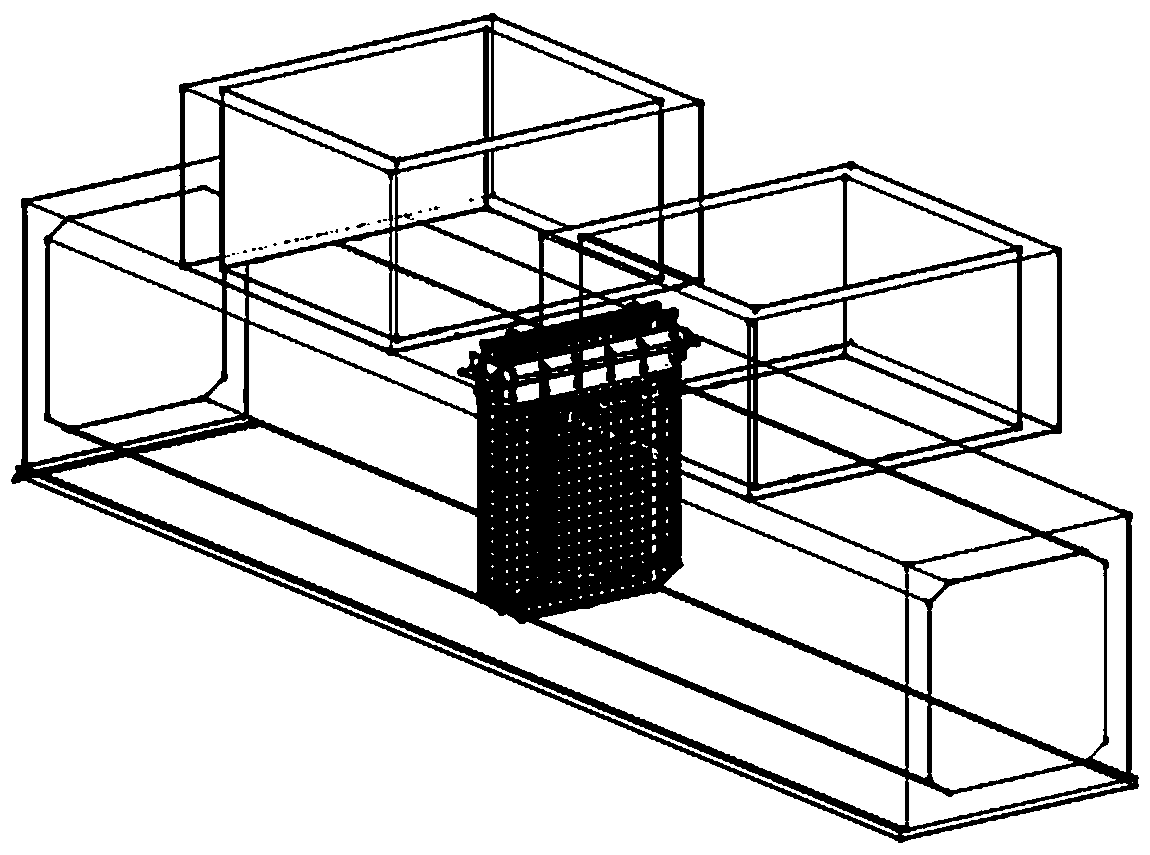

[0023] A fast partition wall for water-holding structures and pipe culverts, characterized in that the fast partition wall includes water-facing panels 1 located on both sides of the fast partition wall, and wall structural steel bars 3 and pre-filled Concrete 5, the area between the pre-filled concrete bottom and both sides between the facing panels on both sides is left to be poured, and the facing panels on both sides of the waiting area are reinforced with pull screws 6, and the upper part of the facing panel is provided with a ring-shaped water stop Pressing plate 9, flexible water-stop measures 7 are arranged on the inner side of the bottom and both side edges of the panel facing the water.

[0024] Further, the annular water-stop pressure plate 9 includes angle steel arranged around the upper part of the quick partition wall, and the side flanges of the angle steel are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com