Evaporation cooling device

An evaporative cooling and condenser technology, used in evaporators/condensers, refrigerators, refrigeration components, etc., can solve problems such as condenser coil corrosion, and achieve energy saving, long service life, and high commercialization potential. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

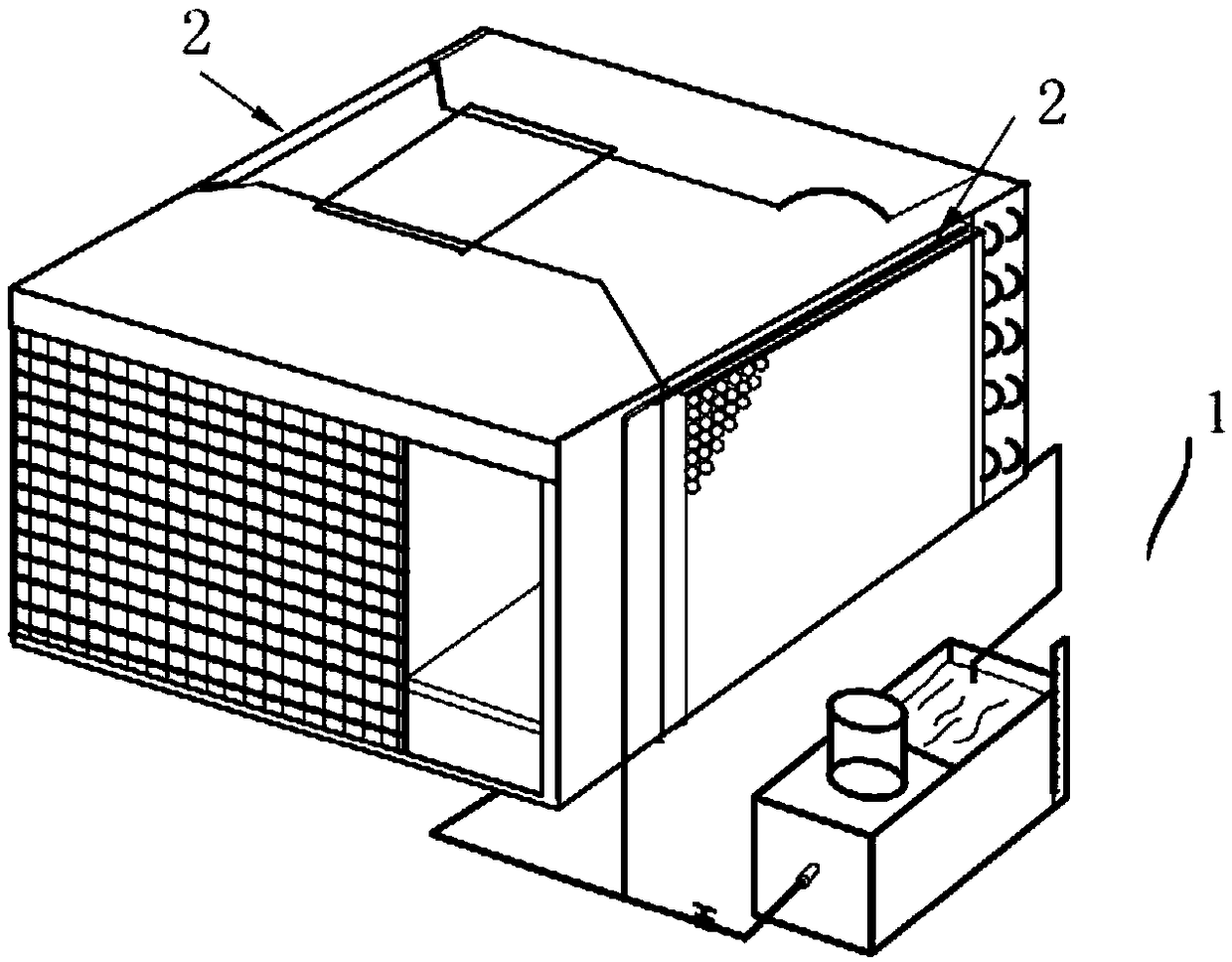

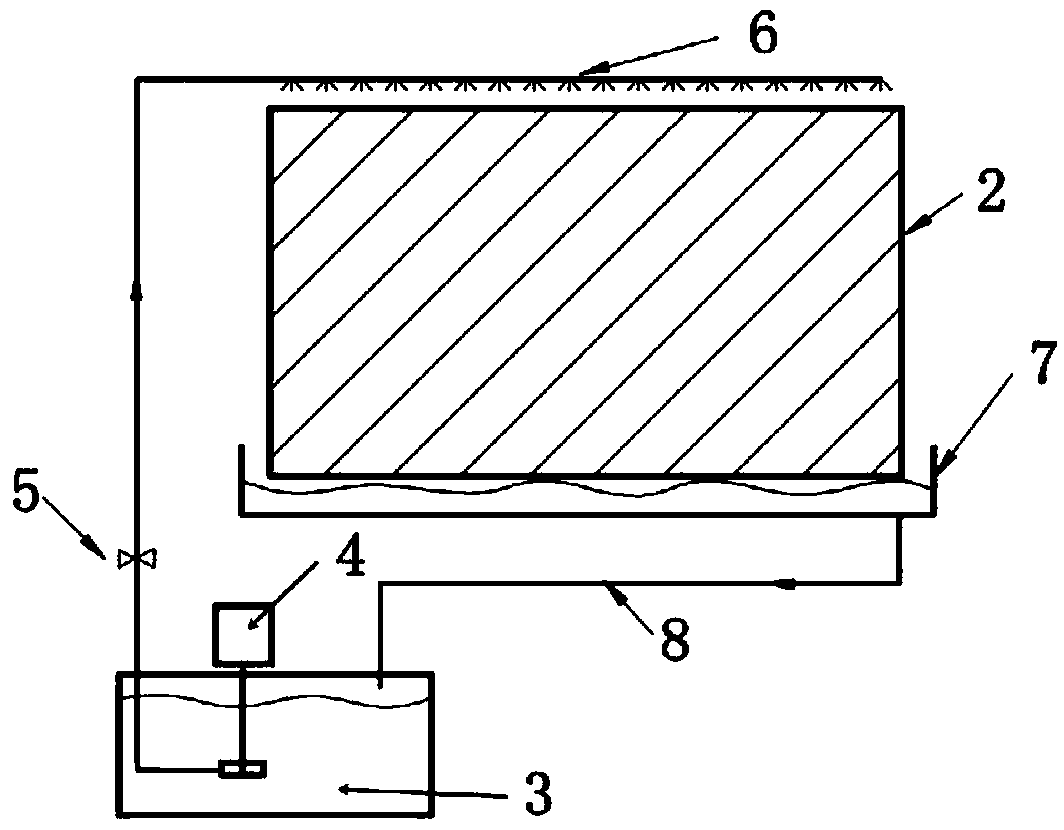

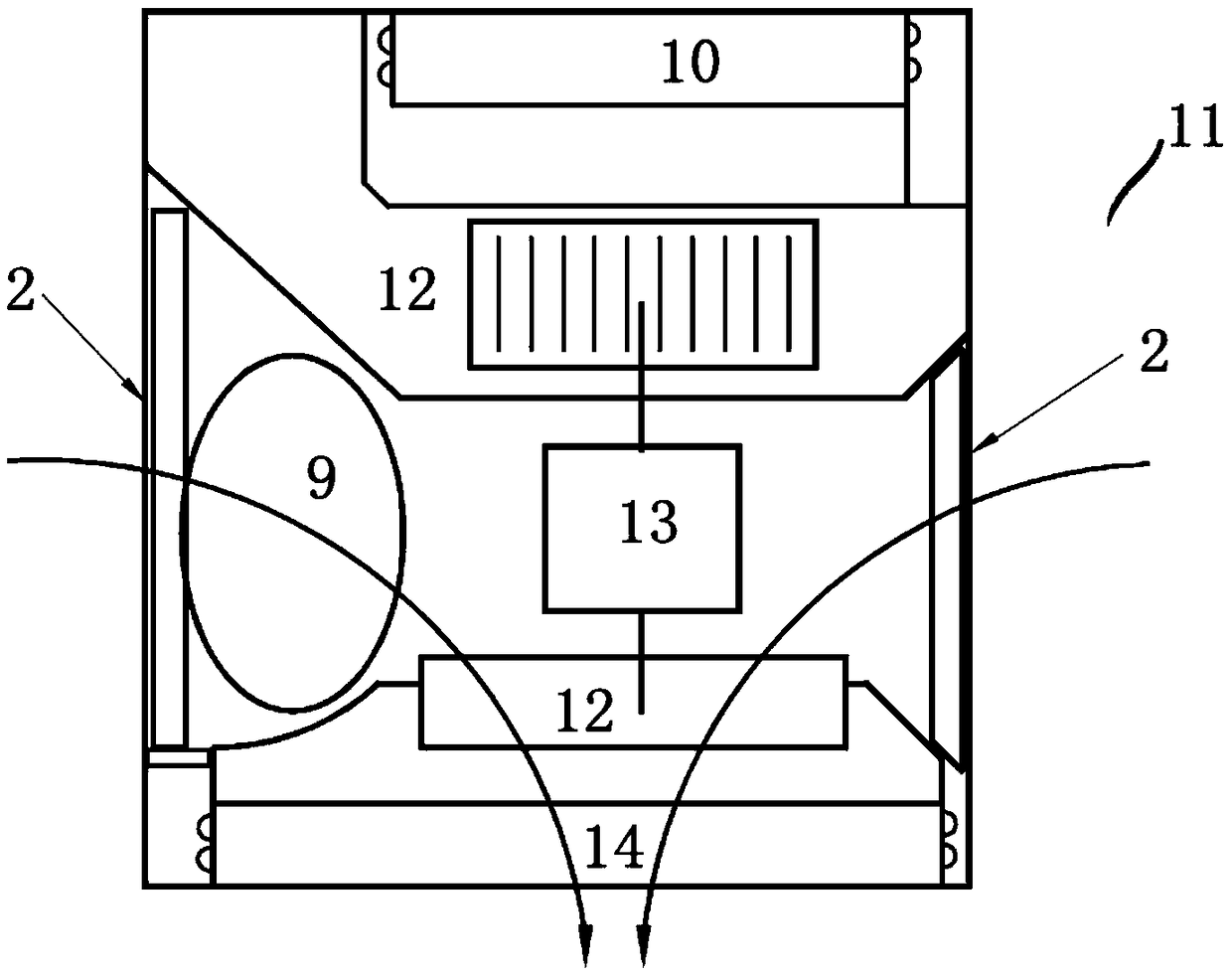

[0015] The evaporative cooling device 1 in this embodiment includes an evaporative medium pad 2 and a water circulation system. Such as figure 1 As shown, in the refrigeration system, two evaporating medium pads are arranged in the air channel above the condenser. In this embodiment, the evaporating medium pad is arranged on both sides of the refrigeration system, and the evaporating medium pad covers 3 / 4 of the side wall area. In this embodiment, the shape of the evaporating medium pad is rectangular, and the shape of the evaporating medium pad can also be adjusted according to the air channels formed in the refrigeration system, for example, it is a curved plate. The thickness of the evaporating medium pad is preferably 3-4 cm. The evaporative media pad of the present invention provides the maximum area available for cooling without in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com