Intelligent proportioning and weighing control system and control method thereof

A control system and intelligent batching technology, which is applied in the program control, electrical program control, weighing and other directions of the sequence/logic controller, can solve problems such as line faults, low degree of automation, and complicated fault handling, and meet the requirements of production Process requirements, convenient real-time monitoring, and the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

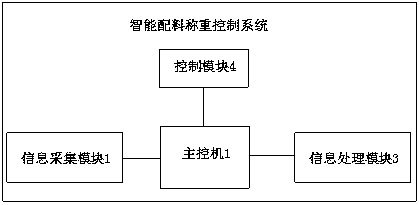

[0055] see figure 1 Shown is a schematic structural view of the first embodiment of an intelligent ingredient weighing control system of the present invention, including:

[0056] A main control machine 1 for setting formula parameters required for batching, the formula parameters including raw material names and raw material weights;

[0057] It is used to detect the weight of various raw materials in the silo and generate raw material information, and send the raw material information to the information collection module 2 of the weighing instrument in real time, and the raw material information includes the name of the raw material and the weight of the raw material;

[0058] Connected to the main control machine 1 and the signal acquisition module 2 respectively, the signal processing module 3 is used to control the weight of raw materials and generate control signals according to the recipe parameters and raw material information, and the control signals are used to repre...

Embodiment approach 2

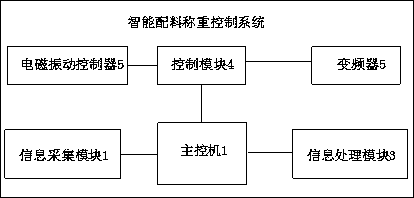

[0063] see figure 2 Shown is a schematic structural diagram of the second embodiment of an intelligent ingredient weighing control system of the present invention. The difference between this embodiment and Embodiment 1 is that the automatic ingredient control system also includes:

[0064] Connected with the control module 4, it is an electromagnetic vibration controller 5 used to control the sequence of raw material delivery.

[0065] It should be noted that different ingredient formulations have different feeding sequences, and the electromagnetic vibration controller 5 can effectively control the feeding sequence.

[0066] It is connected with the control module 4 and is used for controlling the frequency converter 6 of the material conveying speed.

[0067] The user can directly set and observe the feeding frequency through the frequency converter 6, which is convenient for the user to operate.

Embodiment approach 3

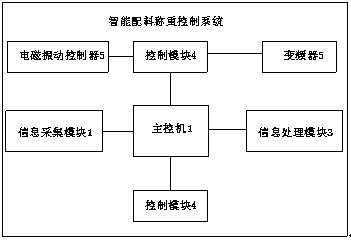

[0069] see image 3 Shown is a schematic structural diagram of the third embodiment of an intelligent batching and weighing control system of the present invention. The difference between this embodiment and the second embodiment is that the automatic batching control system also includes:

[0070] Including an alarm module 7, the control module 4 sends an alarm signal to the signal processing module 3 according to the abnormal operation of each valve, and the signal processing module 3 displays the alarm signal through the main control computer 1.

[0071] The setting of the alarm module 7 facilitates understanding of faults.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com