Pneumatic static lateral pressure instrument and test method thereof

A static side pressure and pressure gauge technology, applied in the measurement of hydraulic/pneumatic force, etc., can solve problems such as insufficient accuracy, low test accuracy, and inaccurate force on soil samples, so as to improve work efficiency and test accuracy , the effect of uniform stress on the soil sample

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be specifically described below according to the drawings and specific embodiments of the invention.

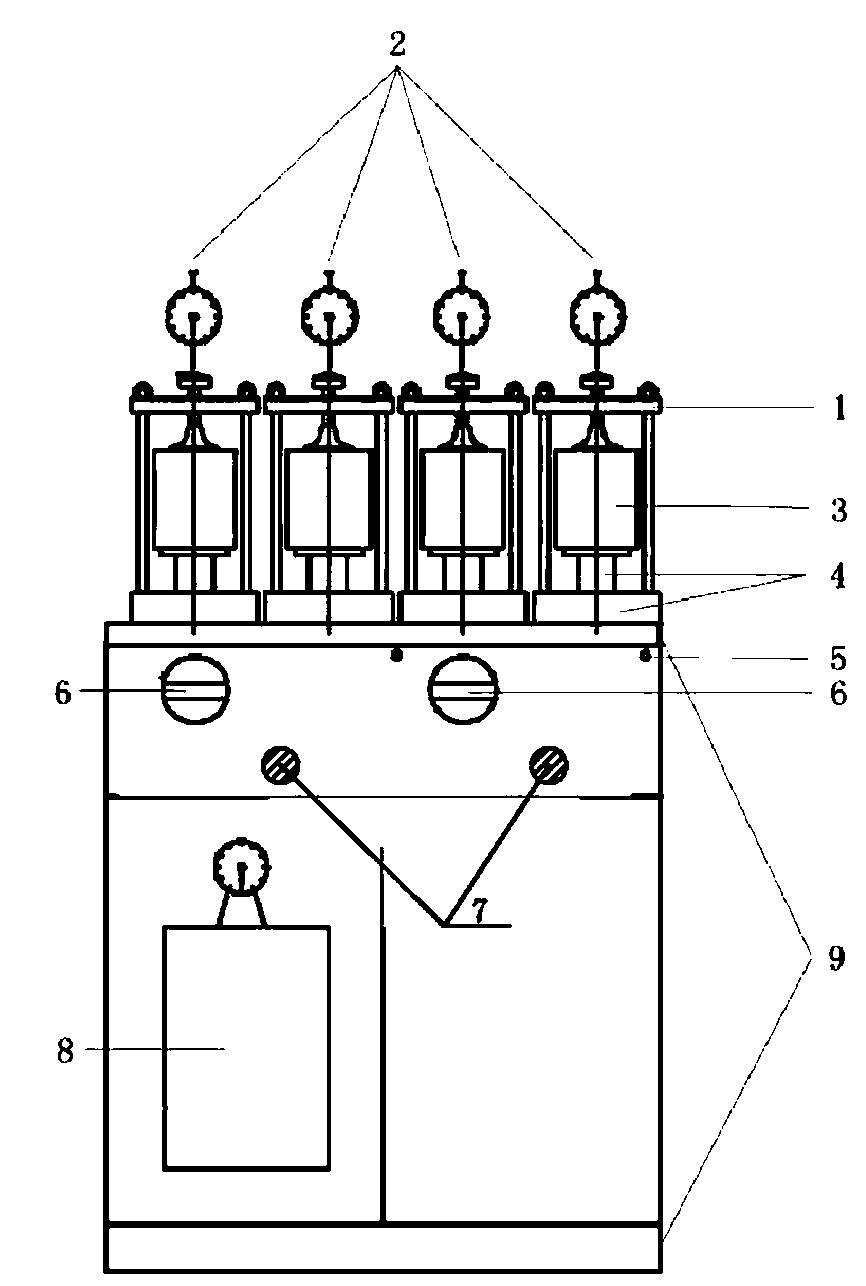

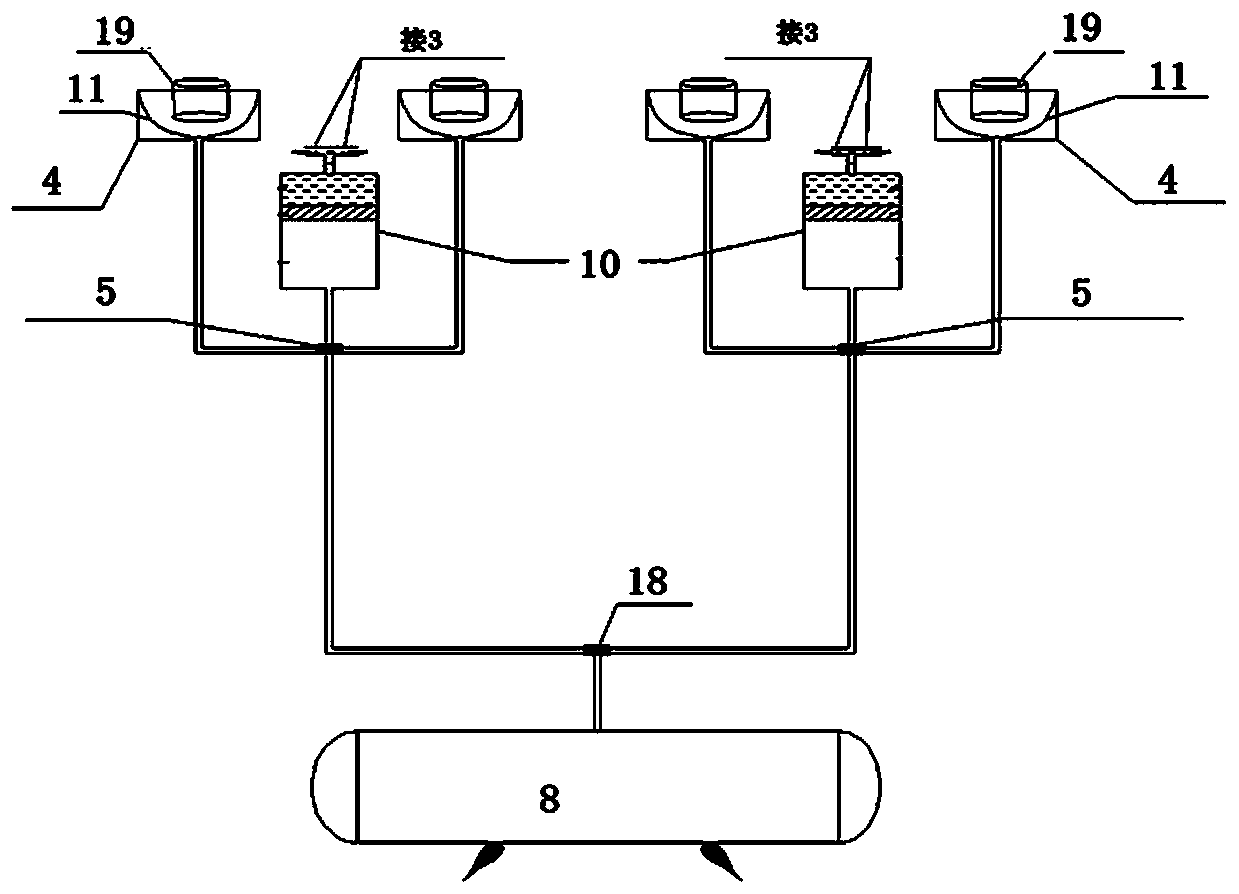

[0026] Such as figure 1 As shown, a pneumatic static side pressure instrument includes a cabinet-type operating table 9, an air compressor 8 is installed in the cabinet-type operating table 9, and an air source solenoid valve 5 is installed on the operation panel of the cabinet-type operating table 9, plus Pressure control device 6, and pressure regulating valve 7, the top of the cabinet type operation table 9 is provided with a pressurized base 4 and a piston guide rod matched with it, the pressurized base 4 is provided with a fixed frame 1, and a stationary side The pressure gauge container 3, the piston guide rod is located at the bottom of the static side pressure gauge container 3, and the displacement sensor 2 connected to the static side pressure gauge container 3 is installed on the top of the fixed frame.

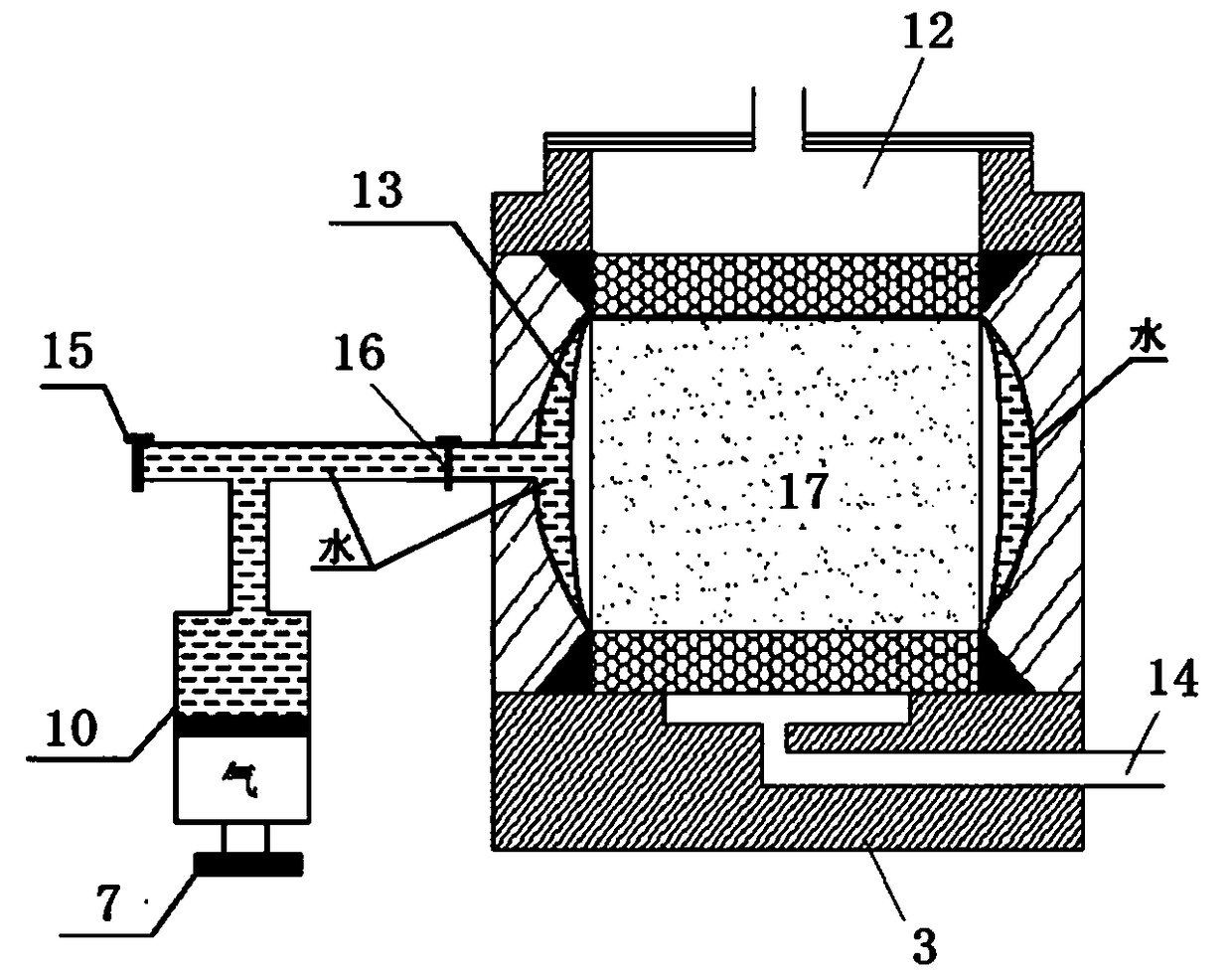

[0027] figure 2 Shown is a sche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com