Pressure finger and contact finger assembly tool

An assembly tooling and contact finger technology, which is applied in the connection/disconnection direction of the connecting device, can solve the problems of the elastic retaining ring 17 popping up, endangering the safety of the operator, and low assembly efficiency, so as to achieve firm and reliable disassembly, high safety, The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

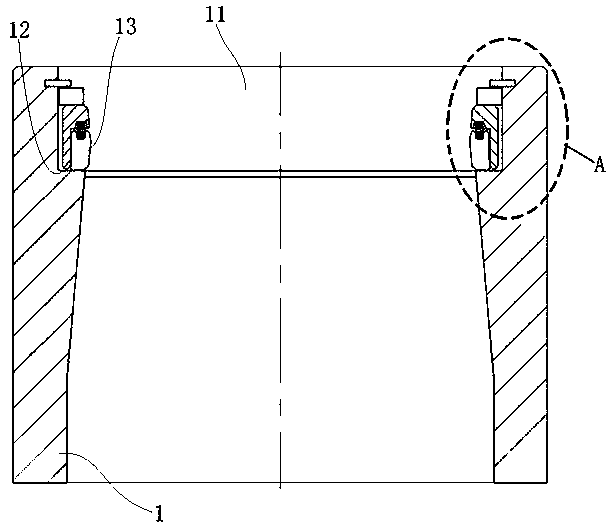

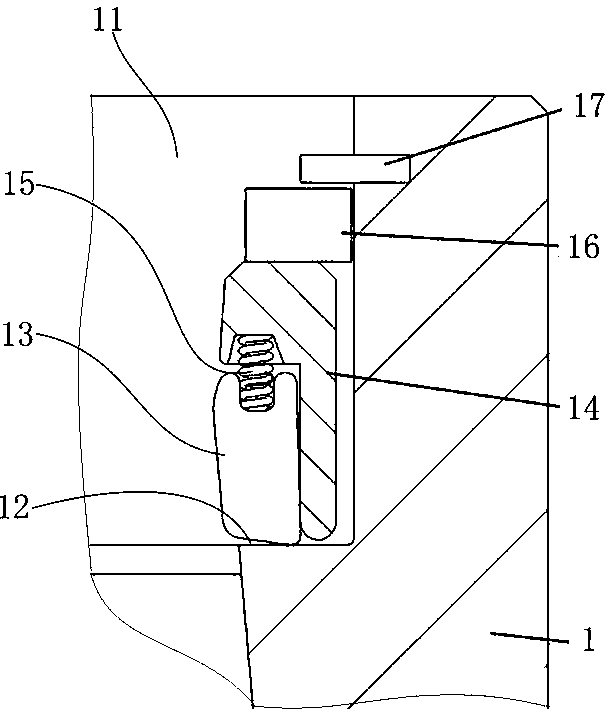

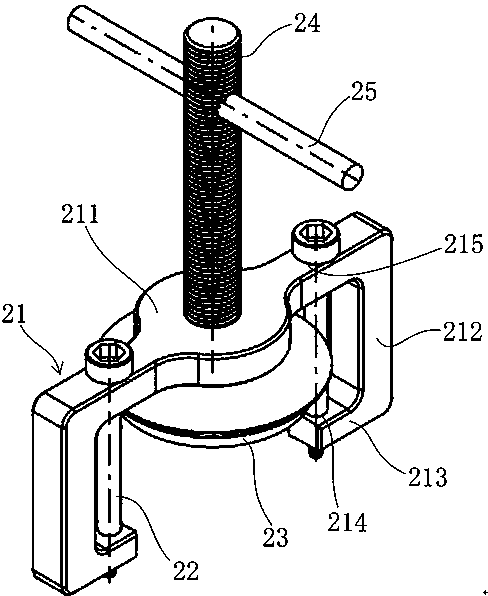

[0025] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] Specific embodiments of the finger-pressing and contact-finger assembly tooling of the present invention, such as Figure 3-7 As shown, the finger-contact finger assembly tool 2 includes a support frame 21 with an open end. The support frame 21 is in an inverted U shape and includes a top wall 211 and a side wall 212. The bottom edge of the side wall 212 is provided with an inward edge 213. A connecting hole 214 for connecting the end surface process hole of the GIL conductor 1 through a bolt 22 is provided on the edge 213, and a piercing hole 215 for the bolt 22 is provided on the top wall 211 coaxially with the connecting hole 214. A long bolt 22 is respectively arranged at the turning edge 213 and the corresponding top wall 211, and the long bolt 22 is coaxially pierced through the penetration hole 215 of the top wall 211 and the connecting hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com