Pull-tab system of vacuum suction molding machine

A technology of vacuum forming and pulling tabs, applied in the field of tabbing systems, can solve the problems of fast servo motor running speed, inability to perform precise adjustment, production of defective products, etc., to reduce labor costs, reduce labor participation in the process, and respond quickly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

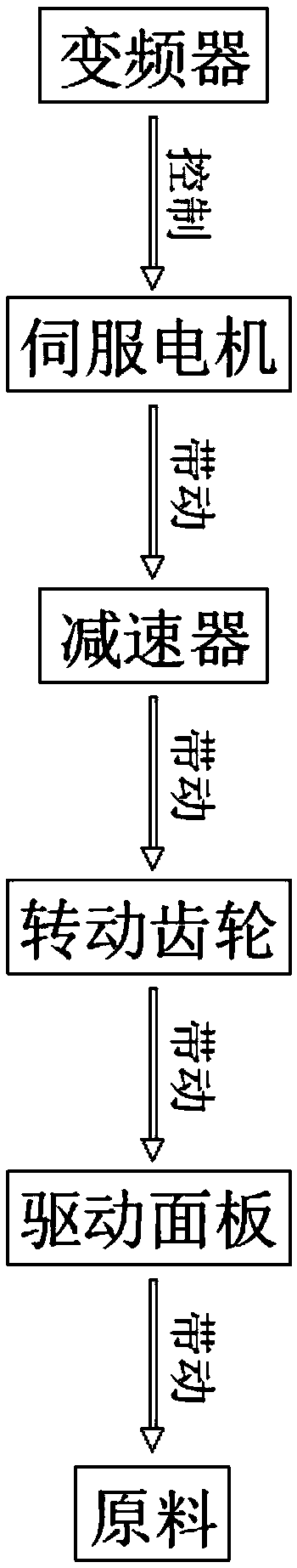

[0026] As a preferred embodiment of the present invention: the frequency converter in step 1 is based on frequency conversion technology and microelectronics technology to change the AC frequency of the power supply to control the servo motor operation, and the model of the frequency converter is S7-1500PLC, and the frequency converter replaces manual adjustment. When the motor is adjusted, it is more precise, has the advantages of fast response and precise adjustment, and reduces manual participation in the process, reduces labor costs, and reduces waste of raw materials, making the probability of waste products lower.

Embodiment 2

[0028] As a preferred embodiment of the present invention: the speed reducer in step 2 plays the role of matching speed and transmission torque between the servo unit and the rotating shaft, and the speed reducer is composed of a transmission gear and a worm, which is convenient for the speed reducer to reduce the transmission speed of the servo motor. Speed, to prevent waste products caused by too fast servo motor speed.

Embodiment 3

[0030] As a preferred embodiment of the present invention: the rotating shaft in step 3 is connected with the transmission gear in the reducer through the connecting gear, the connecting gear is meshed with the transmission gear in the reducer, and the speed of the servo motor is related to the transmission in the reducer After the gear is connected to the worm, the rotating speed has been reduced, and the transmission gear transmits the reduced rotating speed to the connecting gear, and the connecting gear can drive the rotating shaft to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com