Device for folding side edge of K film color-printing packaging bag

A folding device, packaging bag technology, applied in the directions of packaging, transportation and packaging, bag making operations, etc., can solve the problems of reducing the production efficiency and product quality of packaging bags, damaged edge sealing of packaging bags, and difficult operation, etc. and shaking, the product is tightly sealed, and the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

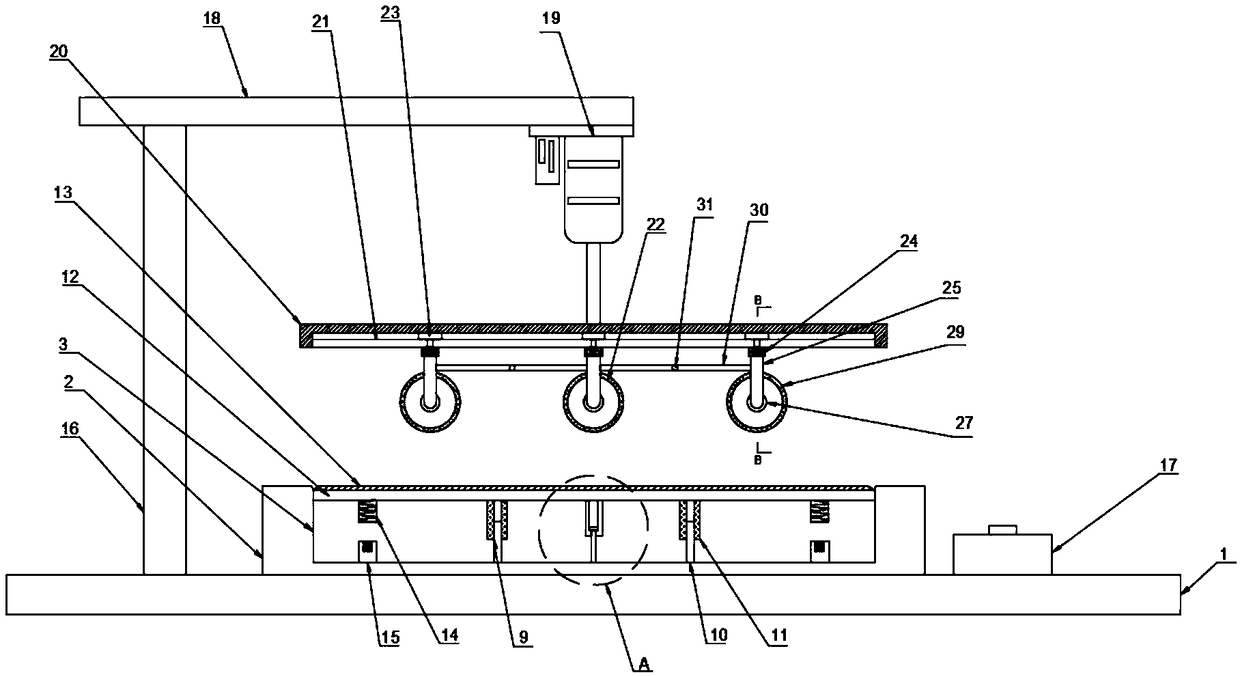

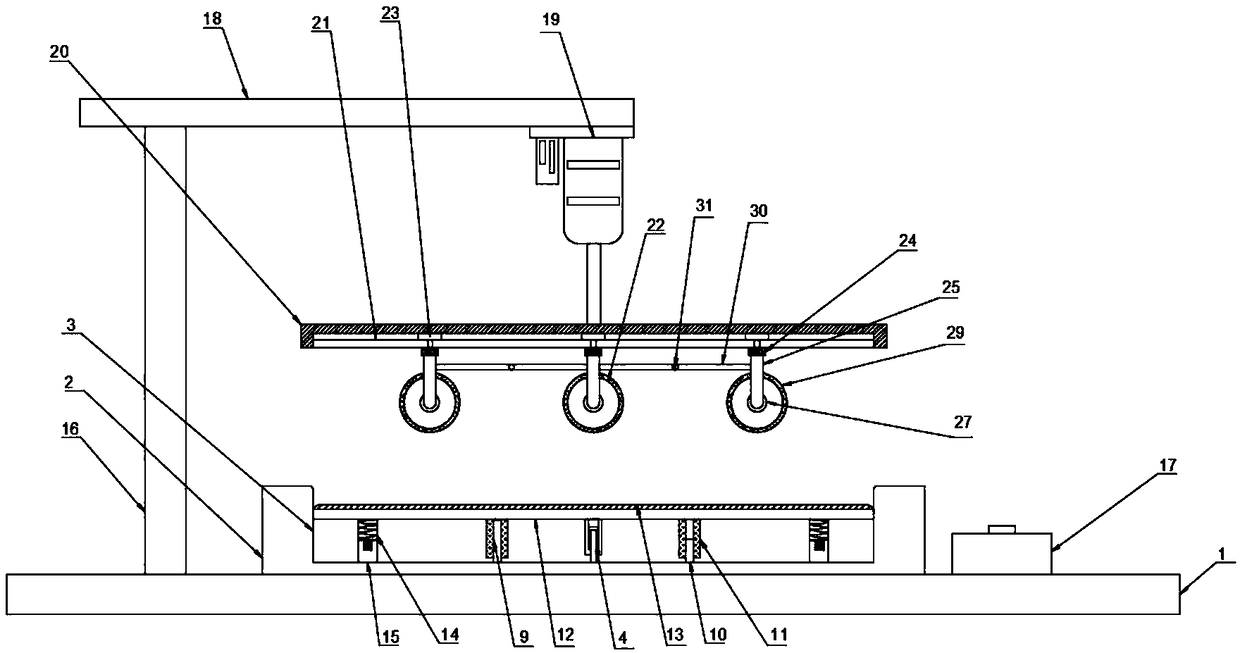

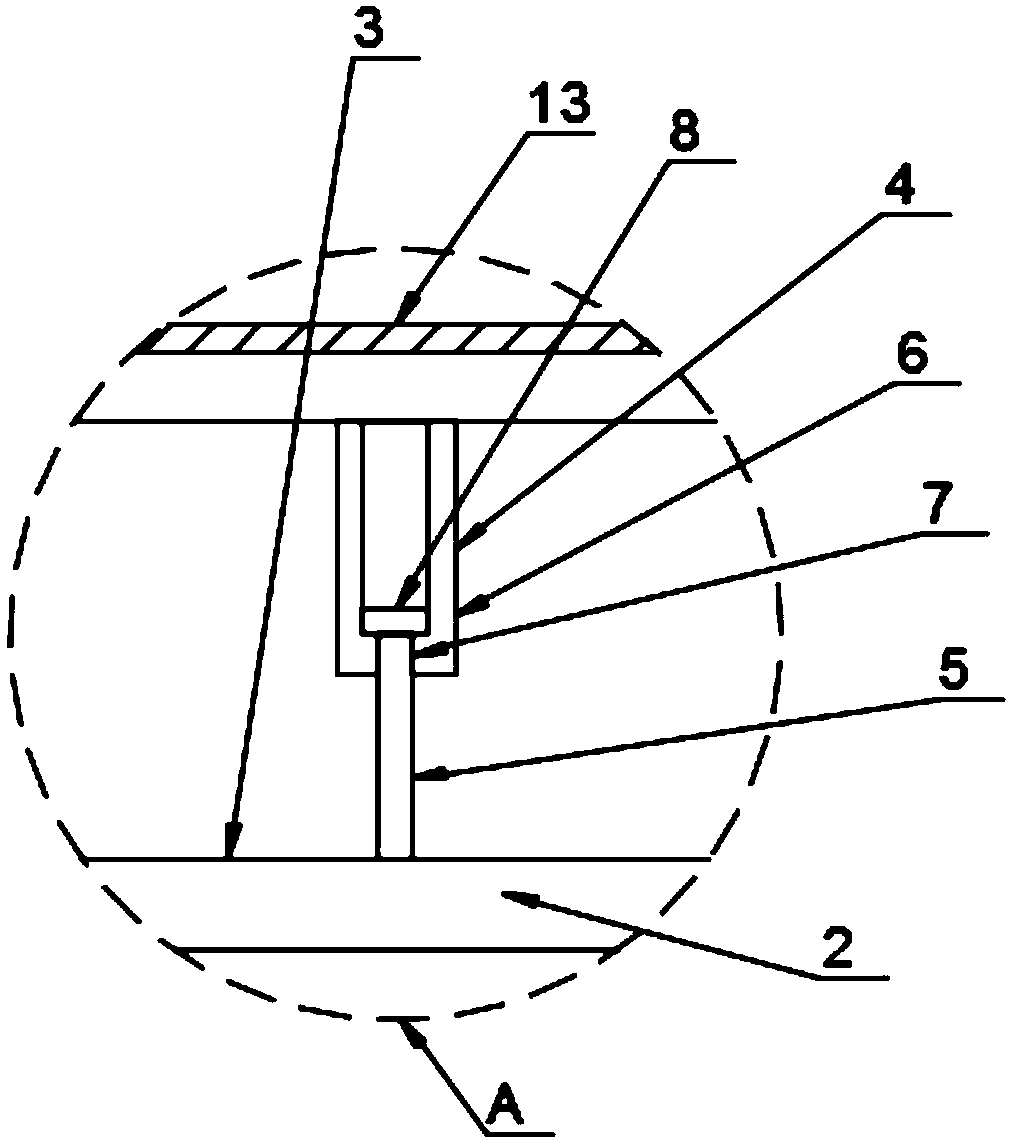

[0029] Such as Figure 1-5 The shown side folding device for K-film color printing packaging bags includes a base plate 1, a workbench 2 is provided on the top of the base plate 1, and a working groove 3 is opened on the top of the workbench 2, and the inside of the working groove 3 is The bottom of the cavity is provided with a limiting device 4, the limiting device 4 includes a limiting rod 5, the outer wall of the limiting rod 5 is provided with a limiting tube 6, and the bottom end of the limiting tube 6 is provided with a limiting hole 7. The top of the limit rod 5 is provided with a limit block 8, and both sides of the limit device 4 are provided with an auxiliary device 9, and the auxiliary device 9 includes a first connecting rod 10, and the outer wall of the first connecting rod 10 is provided with a connecting rod. Pipe 11, the top of the working tank 3 is provided with a folding table 12, the top of the folding table 12 is provided with a rubber pad 13 and the botto...

Embodiment 2

[0033] Such as Figure 1-5 As shown, a side folding device for K-film color printing packaging bags, the control device 17 is provided with a control button, and the control device 17 is provided with a PID controller inside, and the PID controller is arranged on the electric telescopic rod 19 and the input end of the electromagnet 14, the bottom end of the limit rod 5 is fixedly connected with the bottom wall of the working tank 3, and the top end of the limit tube 6 is fixedly connected with the bottom of the folding table 12.

[0034]The limit rod 5 is plugged into the limit hole 7, the outer wall of the limit rod 5 fits the inner wall of the limit hole 7, and the inner diameter of the limit tube 6 is larger than that of the limit hole 7 and the limit rod 5. Diameter, the outer wall of the limiting block 8 is attached to the inner wall of the limiting tube 6, the limiting rod 5 is flexibly connected to the limiting tube 6, the bottom end of the first connecting rod 10 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com