Automatic torque changing cloth rolling method for cloth rolling machine

The technology of a cloth rolling machine and cloth rolling roller is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., which can solve the problems of uneven weight of cloth, affecting the effect of spreading cloth, and difficulty in mass production of system cost. To achieve the effect of improving the quality of the cloth, reducing the bad cloth and constant tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

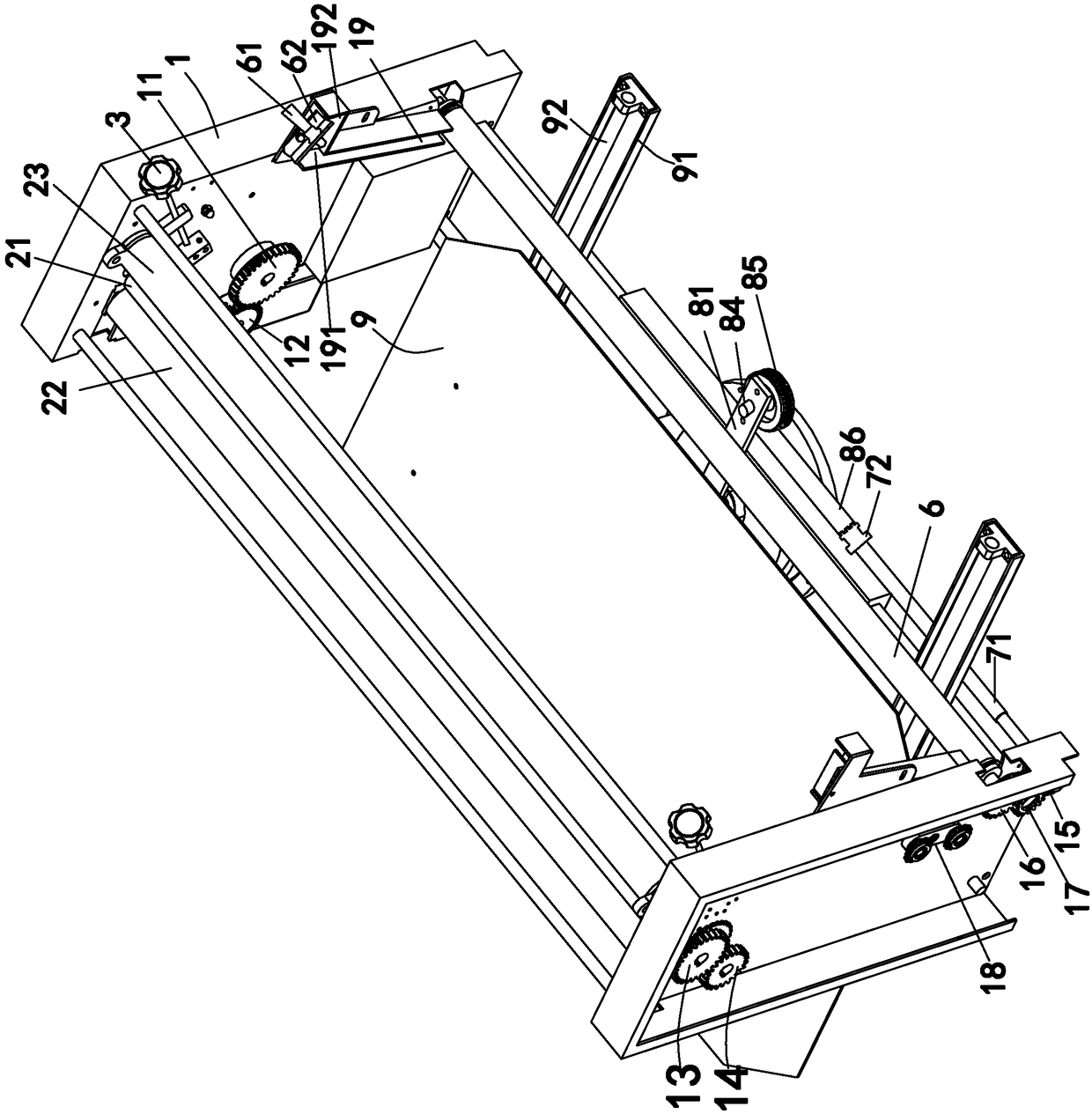

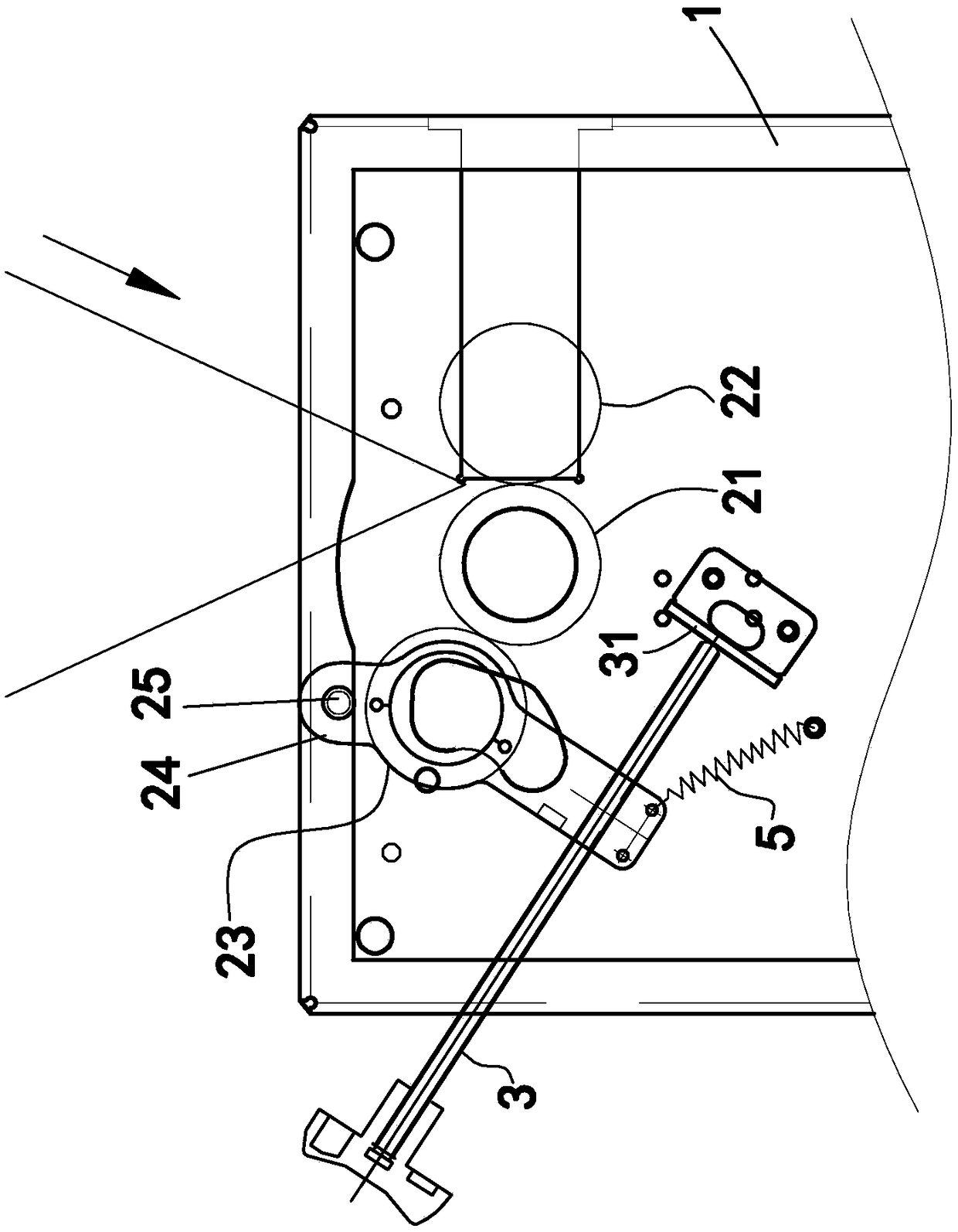

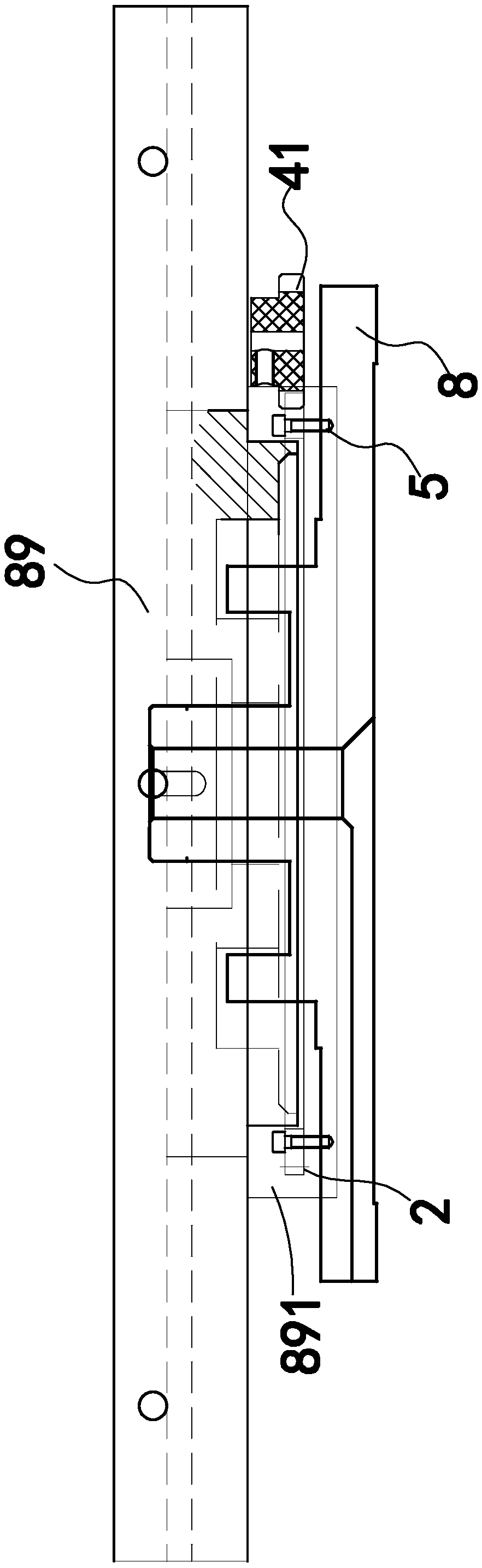

[0021] Such as Figure 1 to Figure 4 , the automatic variable-torque cloth rolling method of the cloth rolling machine of the present invention, the specific steps are:

[0022]1) First, install a proximity switch on the inside of the frame (not shown in the figure) of the large circular knitting machine, and install a servo motor and servo motor drive chip on the rotary frame of the cloth winding machine, and the servo motor is controlled by the PLC control system Rotate the output torque, and then the servo motor drives the pulling roller group and the cloth rolling roller group. The servo motor, the servo motor drive chip, and the proximity switch are electrically connected to the PLC control system. When the cloth winding machine rotates, when the metal detector approaches the switch When close to the sensing area, the proximity switch can send out electrical instructions quickly without contact, without pressure, without sparks, so as to provide control instructions to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com