High-purity graphite powder and preparation method thereof

A technology of high-purity graphite powder and graphite powder, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as inability to remove high melting point carbides, and achieve high practical value and significant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

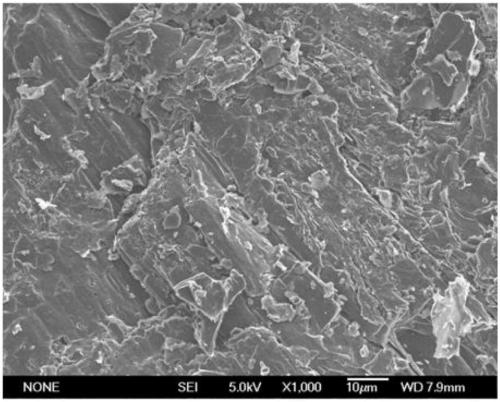

Embodiment 1

[0028] A preparation method of high-purity graphite powder, comprising the steps of:

[0029] S1. Take petroleum coke (purity: 99.85%) with a particle size D50 of 0.5-0.8mm in a graphite boat with a size of φ52×360mm, and put it into GP-0512 graphite with an inner cavity size of φ60×1200mm for purification In the equipment, feed Ar (purity ≥ 99.999%) to purge for 10 minutes, with a flow rate of 20L / h, so that the pressure in the purification equipment is 1.5KPa;

[0030] S2. When the temperature rises to 1600°C, CCl is introduced 4 , the heating rate is 10°C / min, the flow rate is 150L / h, the heat preservation is 2h, and the Ar flow rate is increased to 200L / h;

[0031] S3. Heat up to 2200°C and start feeding CHClF 2 , the heating rate is 1°C / min, the flow rate is 100L / h, the heat preservation is 2h, and the CCl in step S2 is maintained 4 and Ar flow constant;

[0032] S4, heating up to 2800°C to stop feeding CCl 4 and CHClF 2 , the heating rate was 1°C / min, the temperatu...

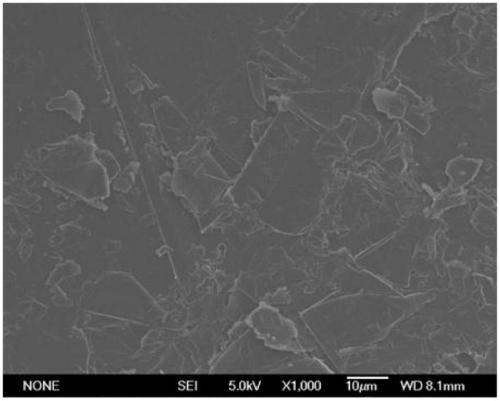

Embodiment 2

[0035] A preparation method of high-purity graphite powder, comprising the steps of:

[0036] S1. Take flake graphite (purity: 99.5%) with a particle size D50 of 0.5-1.0mm in a graphite boat with a size of φ52×360mm, and put it into the graphite purification equipment GP-0512 with an inner cavity size of φ60×1200mm after loading. , feed Ar (purity ≥ 99.999%) to purge for 5 minutes, flow rate 20L / h, so that the pressure in the purification equipment is 1.7KPa;

[0037] S2. Raise the temperature to 1650°C and start to feed CCl 4 , the heating rate is 15°C / min, the flow rate is 100L / h, the heat preservation time is 0.5h, and the Ar flow rate is increased to 200L / h;

[0038] S3. Heat up to 2300°C and start feeding CHClF 2 , heating rate 3°C / min, flow rate 100L / h, heat preservation 2h, maintain CCl in step S2 4 and Ar flow constant;

[0039] S4. Heating up to 2850°C and stopping the introduction of CCl 4 and CHClF 2 , the heating rate was 3°C / min, the temperature was kept for...

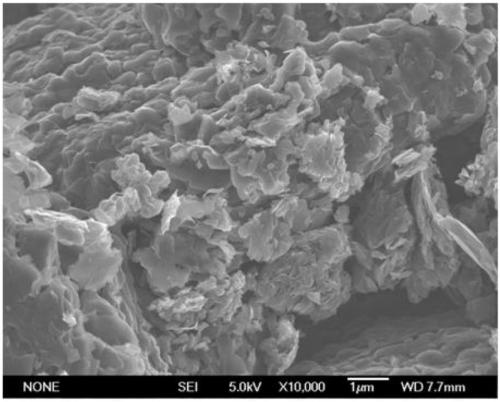

Embodiment 3

[0042] S1. Take microcrystalline graphite (purity: 99.7%) with a particle size D50 of 0.5-1.0mm in a graphite boat with a size of φ52×360mm, and put it into a graphite purification equipment with an inner cavity size of φ60×1200mm after loading. In 0512, pass Ar (purity ≥ 99.999%) to purge for 10 minutes, with a flow rate of 20L / h, so that the pressure in the purification equipment is 1.8KPa;

[0043] S2. When the temperature rises to 1700°C, CCl is introduced 4 , the heating rate is 13°C / min, the flow rate is 200L / h, the heat preservation is 1h, and the Ar flow rate is increased to 200L / h;

[0044] S3. Heat up to 2300°C and start feeding CHClF 2 , heating rate 2°C / min, flow rate 75L / h, heat preservation 1.5h, maintain CCl in step S2 4 and Ar flow constant;

[0045] S4. Heating up to 2850°C and stopping the introduction of CCl 4 and CHClF 2 , the heating rate was 2°C / min, the temperature was kept for 0.8h, the Ar flow rate was reduced to 25L / h, and the temperature was low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com