Self-repairing ultra-sensitive conductive electronic skin sensor material and preparation method thereof

A conductive electronic and self-repairing technology, which is applied in the measurement of the properties and forces of piezoelectric resistance materials, can solve the problem of single function, and achieve the effects of sensitive conductivity, good biocompatibility, and excellent chemical crosslinking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Preparation of anthocyanin-coated graphene oxide:

[0021] First, weigh 0.1 g of graphene oxide and add it to 100 ml of water. After being dispersed evenly by ultrasonic treatment, add 0.05 g of anthocyanin, and adjust the pH value of the solution to 8. Stir and react at 60°C for 8 hours; finally, at 20,000 rpm The graphene oxide / anthocyanin complex is obtained by separating in a centrifuge.

[0022] (2) Preparation of self-healing ultrasensitive conductive electronic skin sensor materials:

[0023] Add 0.15 g of graphene oxide / anthocyanin complex into 20 ml of glycerin / water solution (the volume ratio of glycerol to water is 9:1), disperse evenly by ultrasonic treatment, then add 3 g of polyvinyl alcohol (PVA), heat The PVA was completely dissolved at 95°C; finally, 5 ml of 5wt% borax solution was added dropwise to prepare a self-healing ultrasensitive electronic skin sensor material.

Embodiment 2

[0025] (1) Preparation of anthocyanin-coated graphene oxide:

[0026] First, weigh 0.2 g of graphene oxide and add it to 100 ml of water. After being dispersed evenly by ultrasonic treatment, add 0.1 g of anthocyanin, and adjust the pH value of the solution to 8. Stir and react at 60°C for 8 hours; finally, at 20,000 rpm The graphene oxide / anthocyanin complex is obtained by separating in a centrifuge.

[0027] (2) Preparation of self-healing ultrasensitive conductive electronic skin sensor materials:

[0028] Add 0.3 g of graphene oxide / anthocyanin complex into 20 ml of glycerin / water solution (the volume ratio of glycerol to water is 9:1), disperse evenly by ultrasonic treatment, then add 6 g of polyvinyl alcohol (PVA), heat The PVA was completely dissolved at 95°C; finally, 5 ml of 5wt% borax solution was added dropwise to prepare a self-healing ultrasensitive electronic skin sensor material.

Embodiment 3

[0030] (1) Preparation of anthocyanin-coated graphene oxide:

[0031] First, weigh 0.3 g of graphene oxide and add it to 100 ml of water. After being dispersed evenly by ultrasonic treatment, add 0.15 g of anthocyanin, and adjust the pH value of the solution to 8, and stir and react at 60°C for 8 hours; finally, at 20,000 rpm The graphene oxide / anthocyanin complex is obtained by separating in a centrifuge.

[0032] (2) Preparation of self-healing ultrasensitive conductive electronic skin sensor materials:

[0033] Add 0.45 g of graphene oxide / anthocyanin complex into 20 ml of glycerin / water solution (the volume ratio of glycerol to water is 9:1), disperse evenly by ultrasonic treatment, then add 9 g of polyvinyl alcohol (PVA), heat The PVA was completely dissolved at 95°C; finally, 5 ml of 5wt% borax solution was added dropwise to prepare a self-healing ultrasensitive electronic skin sensor material.

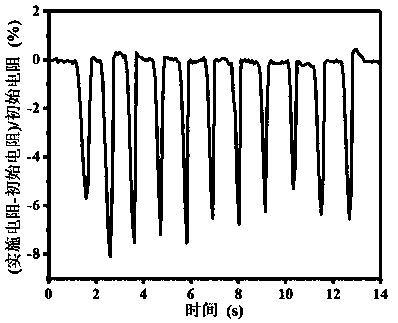

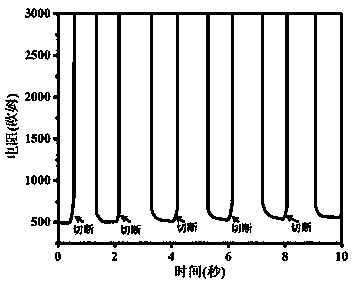

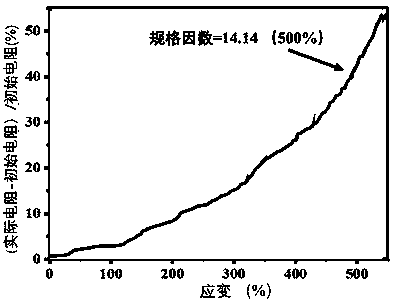

[0034] Performance Testing

[0035] This self-healing ultrasensitive con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com