Improved hybrid energy-storage single tank

An improved, heat storage technology, applied in the direction of heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the difference between effective heat storage and heat release, low heat storage and heat release efficiency of heat storage tanks, and investment costs. higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

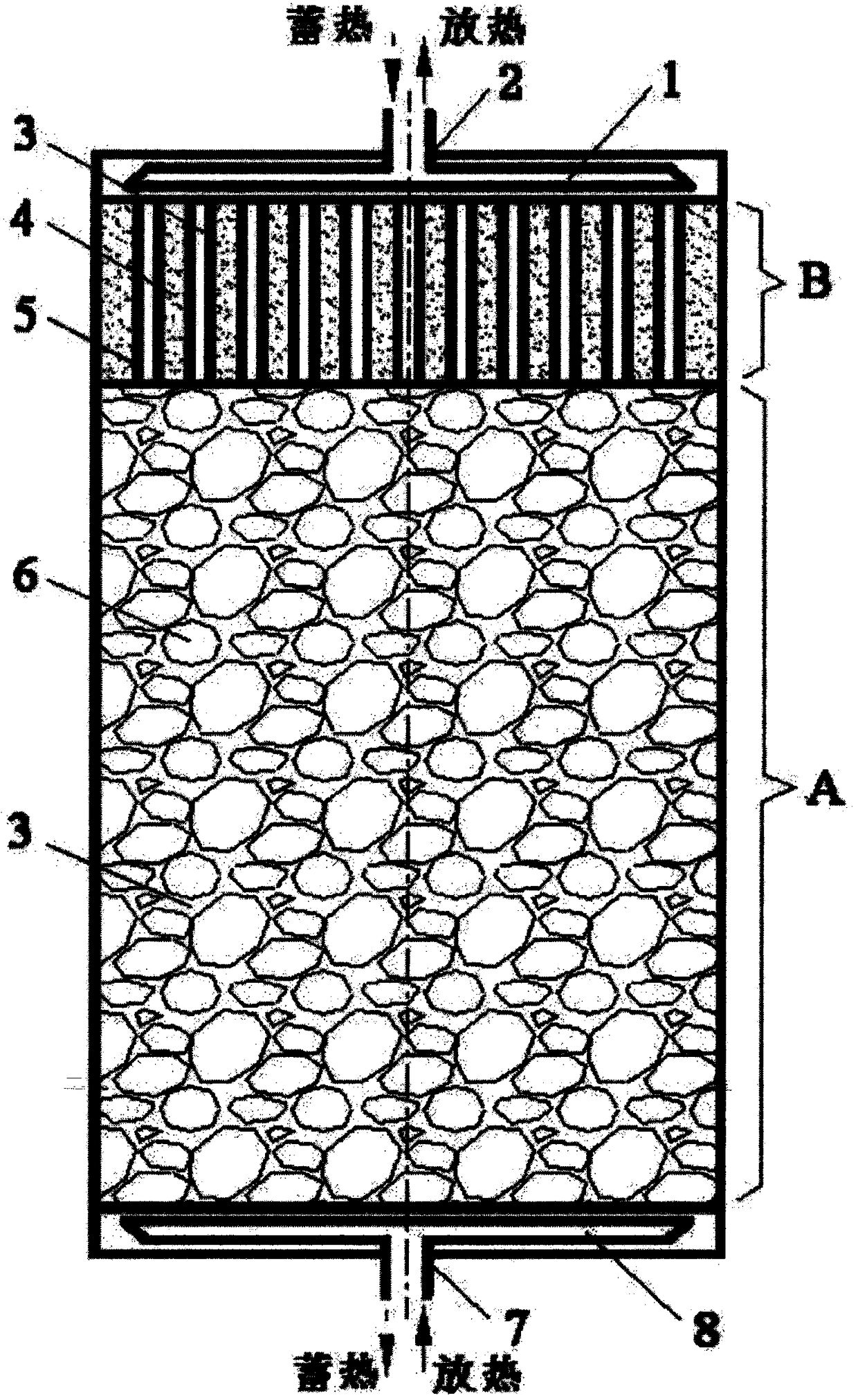

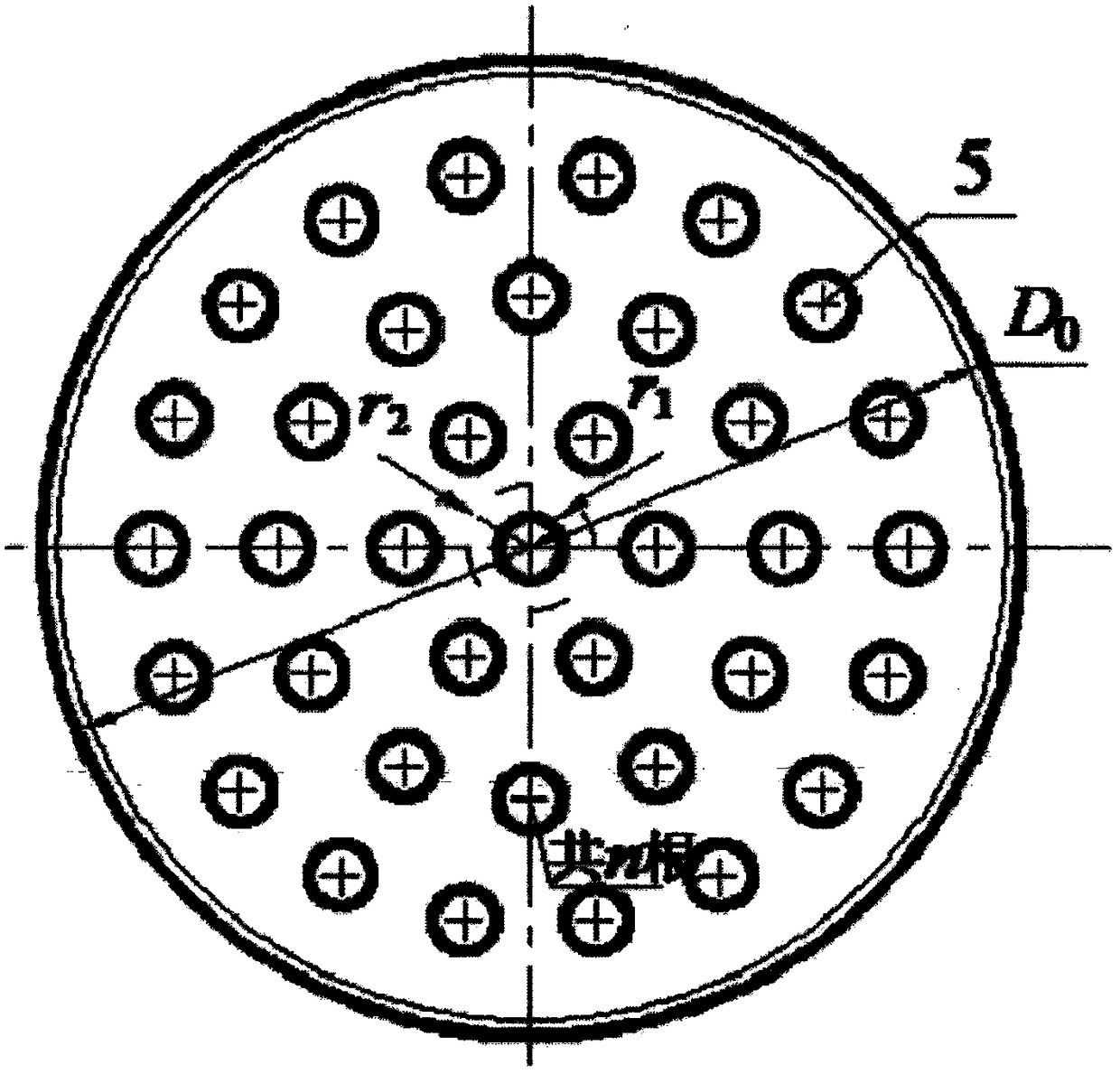

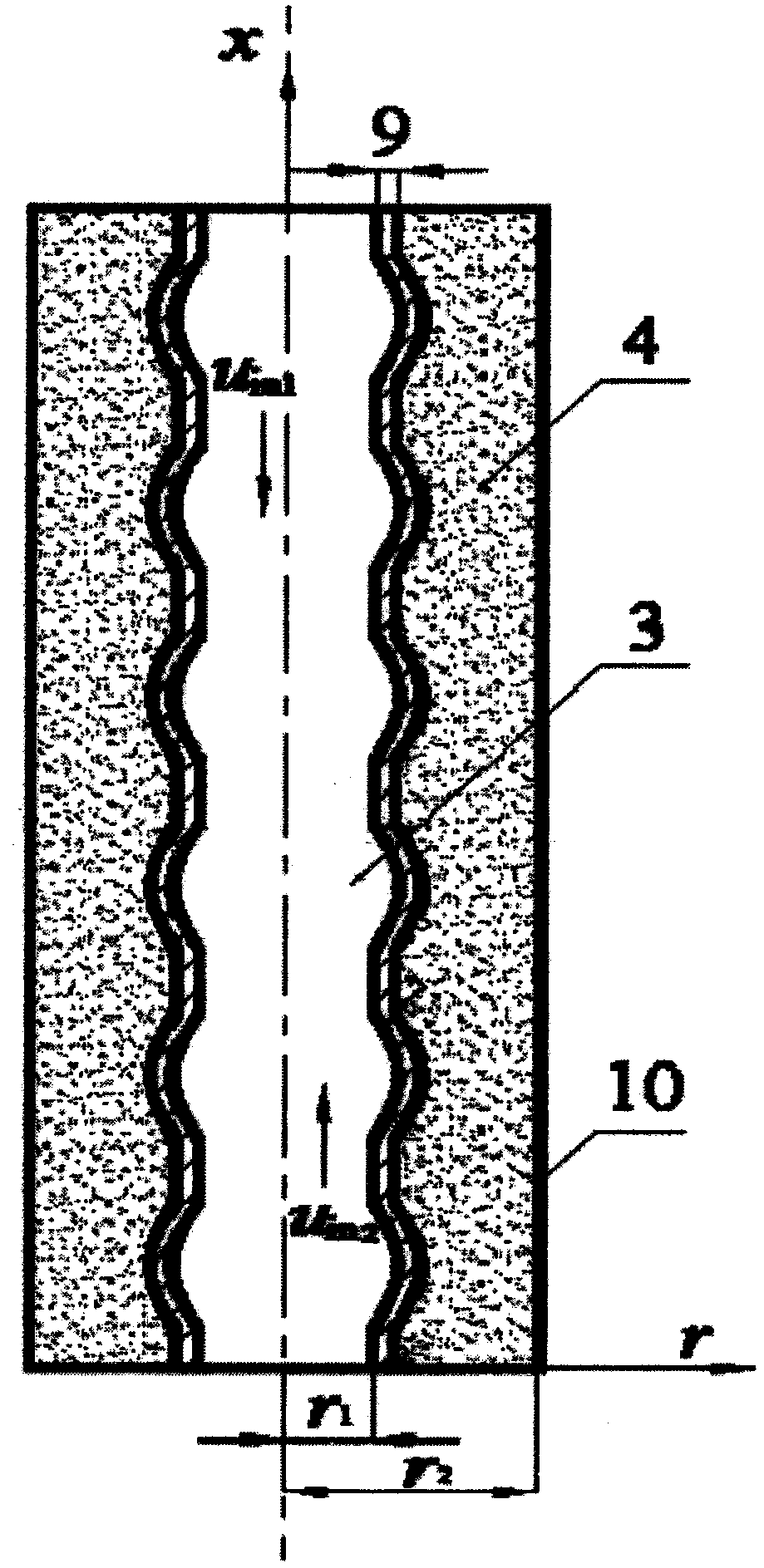

[0019] Such as figure 1 As shown, an improved hybrid heat storage single tank of the present invention includes a phase change heat accumulator B, a thermocline heat storage single tank A, molten salt 3, a phase change heat storage material 4, and a shell-and-tube heat exchanger Pipeline 5, porous medium packing 6, diffuser 1 on the upper side and diffuser 8 on the lower side. The phase change heat accumulator B is closely connected up and down with the thermocline heat storage single tank A, and the thermocline heat storage single tank A is filled with a large amount of porous medium filler 6, the shell and tube heat exchanger pipe 5 and the phase change heat storage material 4 are all arranged in the phase change heat accumulator B, the upper side diffuser 1 is installed on the upper part of the phase change heat accumulator B and is externally connected to the top inlet 2 of the tank body, and the lower side diffuser 8 is installed in the thermocline heat storage single tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com