Automatic detection equipment for short shaft parts

An automatic detection and parts technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of high labor intensity, low efficiency, and low automation level of operators, and achieve the effects of saving manpower, improving production efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

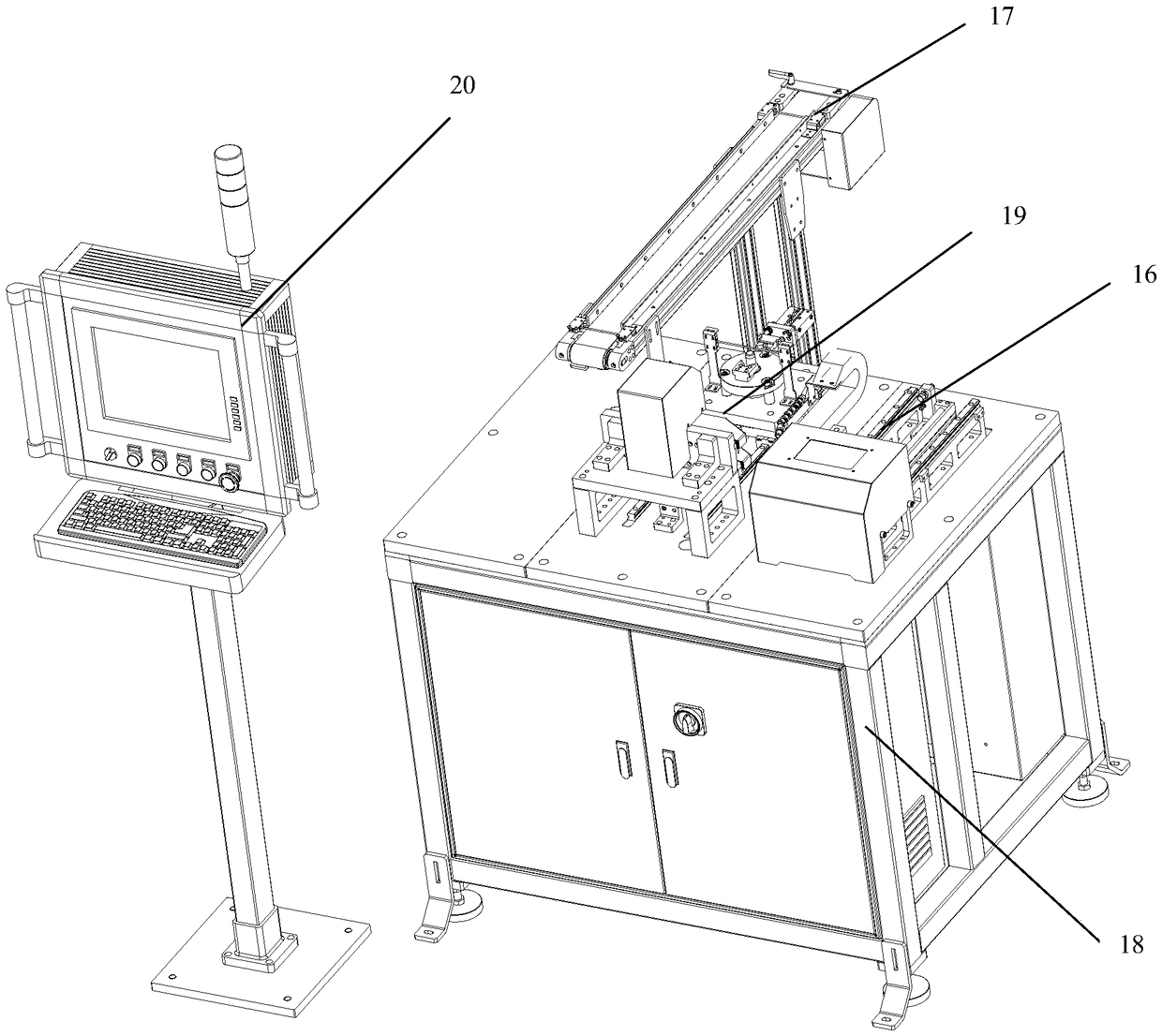

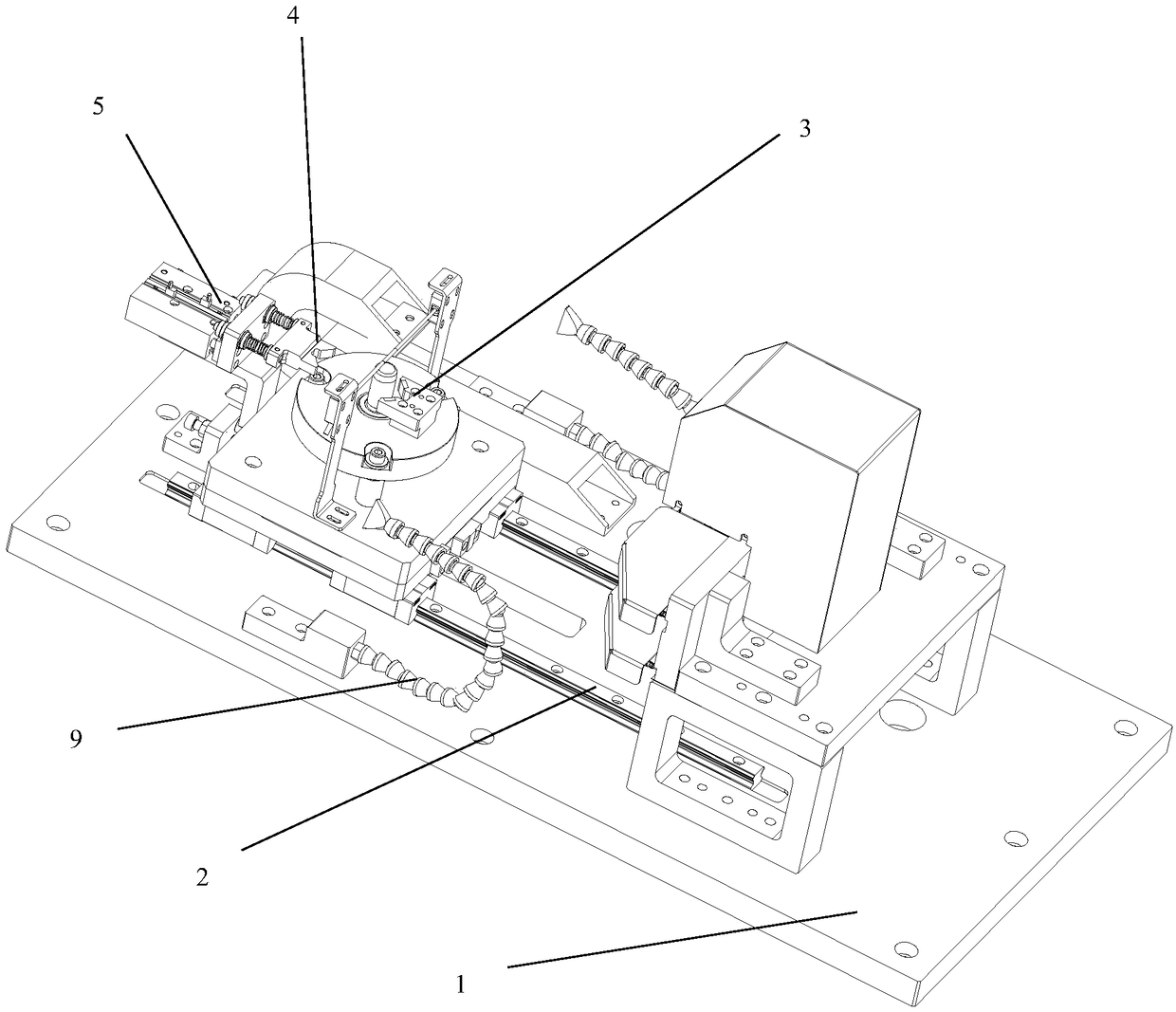

[0028] The invention is mainly aimed at a complete set of automatic detection equipment developed for short shaft parts. The whole set of equipment consists of three parts: automatic detection part, automatic sorting part and automatic calibration part. Each part is of modular design and can be configured and used separately. The automatic detection department can automatically position and measure parts, saving workers' operation time. The automatic sorting department can screen the measured workpieces, reject unqualified ones directly, and pass the qualified ones to the next process. Automatic calibration can automatically calibrate the sensor and measuring head, saving workers' operation time.

[0029] The overall component assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com