Parameter characterization device and detection method for surface defect of high reflection lens of laser gyro

A high-reflecting mirror, laser gyro technology, applied in the direction of using optical devices, measuring devices, scattering characteristics measurement, etc., can solve the problems of long detection time, low detection efficiency, etc., to achieve strong energy, simple implementation, fast, precise and accurate measurement. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the drawings and embodiments.

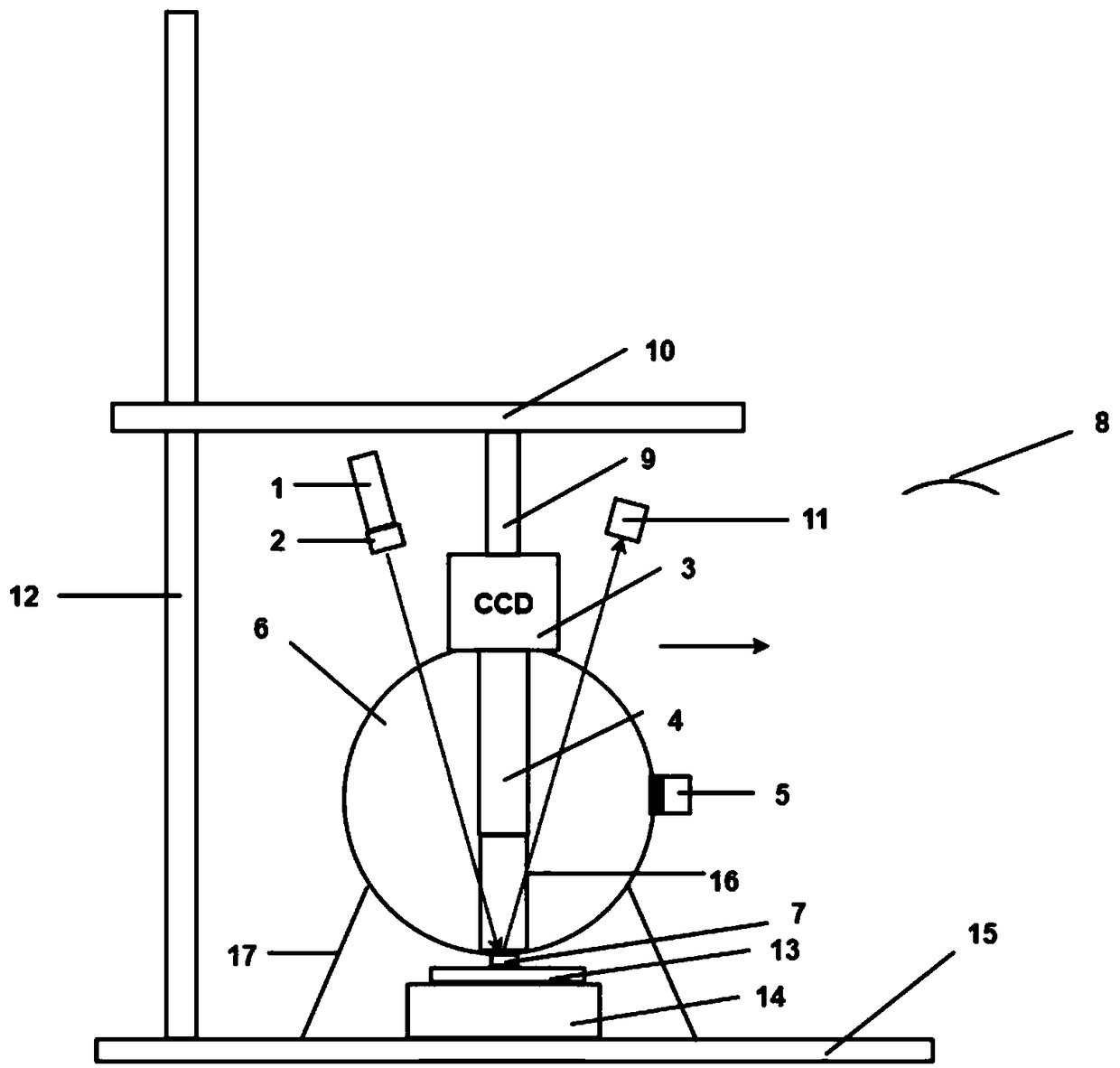

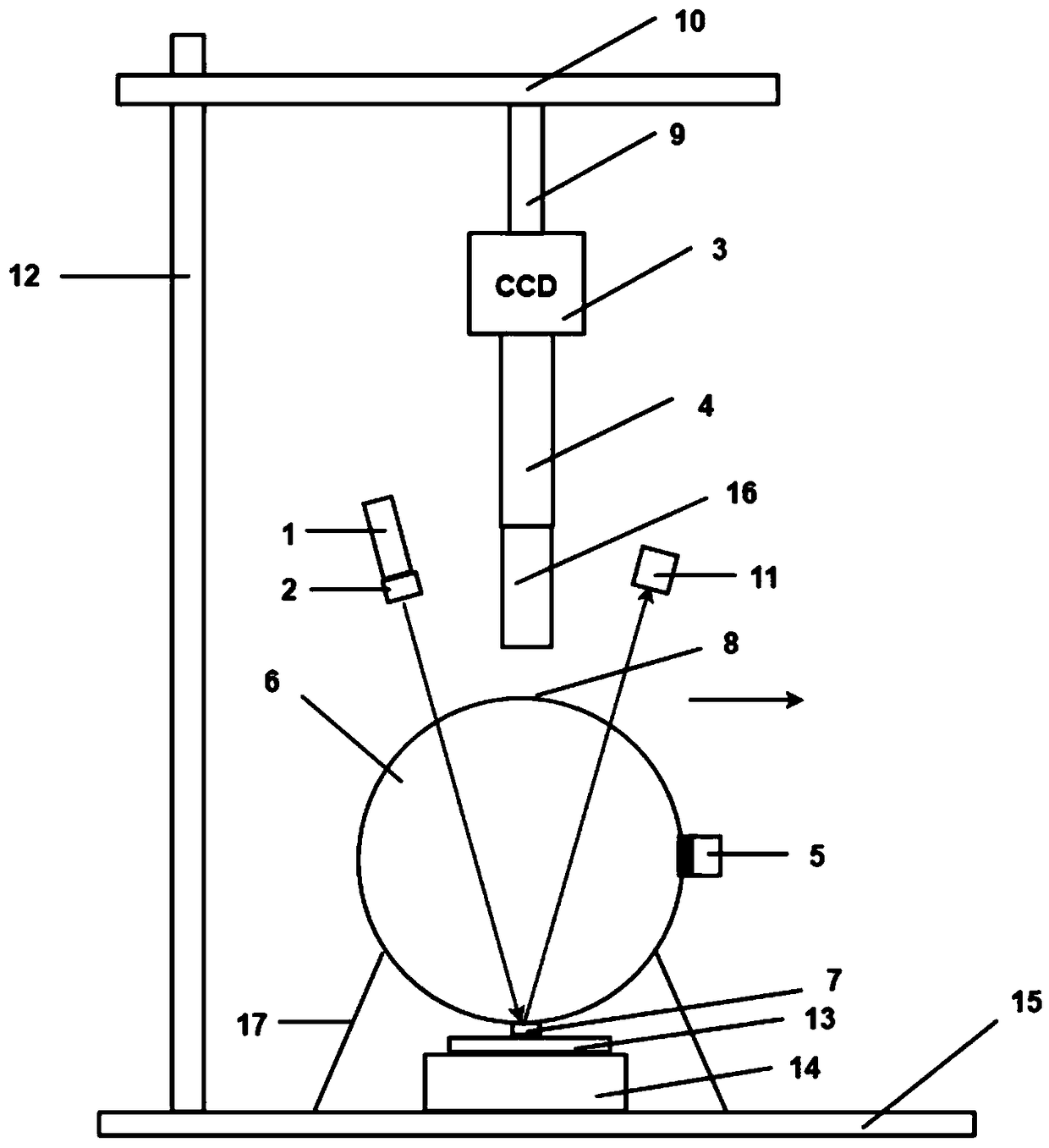

[0024] refer to figure 1 , a laser gyro high reflection mirror surface flaw parameter characterization device, composed of an integrating sphere 6, an integrating sphere detector 5, a CCD imaging component, a semiconductor laser 1 and a light trap 11. The CCD imaging assembly is composed of a CCD camera 3, a microscope lens 4 and a light-shielding cylinder 16. The inside of the light-shielding cylinder 16 is blackened, the integrating sphere 6 is provided with a movable top cover 8, and the sample to be measured 7 is clamped on the sample holder. 13 and the opposite outer wall of the upper cover 8 of the integrating sphere 6, the CCD imaging assembly is arranged directly above the sample 7 to be tested, the laser 1 and the light trap 11 are symmetrically arranged on both sides of the CCD camera 3, and the incident light of the laser 1 A beam shaping component 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com