An Industrial Online Optical Microscopic Imaging System

An imaging system and optical microscopy technology, applied in optics, microscopes, optical components, etc., can solve problems such as human errors, misjudgments, and damage to the health of operators, and achieve the effects of stable work, timely image acquisition, and adjustable brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

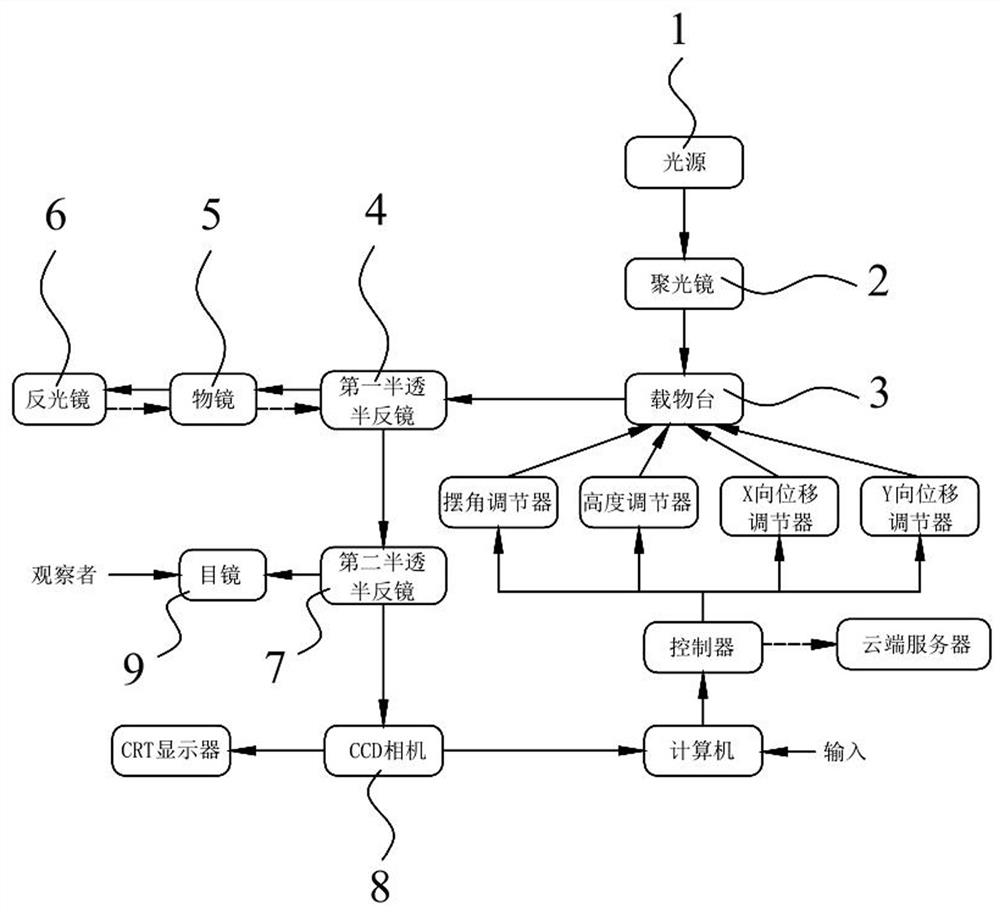

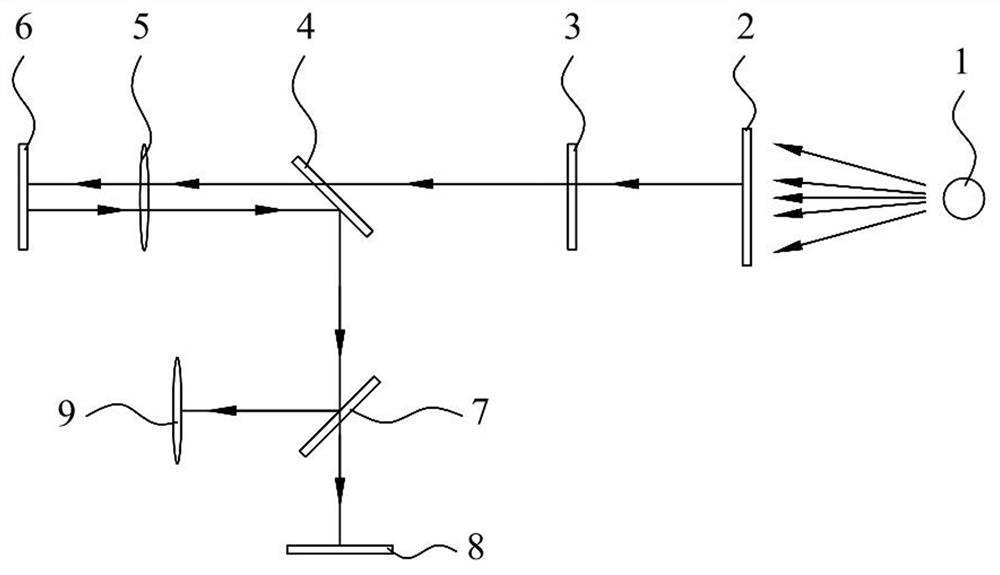

[0020] An industrial on-line optical microscopic imaging system includes a computer, a CRT display, a controller, an imaging system, and an imaging adjustment module. The imaging system includes a light source 1, a condenser lens 2, an object stage 3, a half-transparent mirror, and an objective lens 5, mirror 6, eyepiece 9, CCD camera 8, wherein, half-mirror is divided into first half-mirror 4 and second half-mirror 7; Described imaging adjustment module comprises swing angle regulator , Z-direction displacement regulator, X-direction displacement regulator, Y-direction displacement regulator, described swing angle regulator comprises the first motor, the first transmission box, the rotating shaft, the output shaft of the first mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com