Complete set of thermodynamic calculation method suitable for Claus oven

A thermal calculation and a complete set of technologies, applied in chemical instruments and methods, sulfur preparation/purification, chemical process analysis/design, etc., can solve problems such as difficult to obtain design solutions, difficult to predetermine appropriate size and thermal parameters, and no thermal balance , to achieve the effect of convenient modification and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

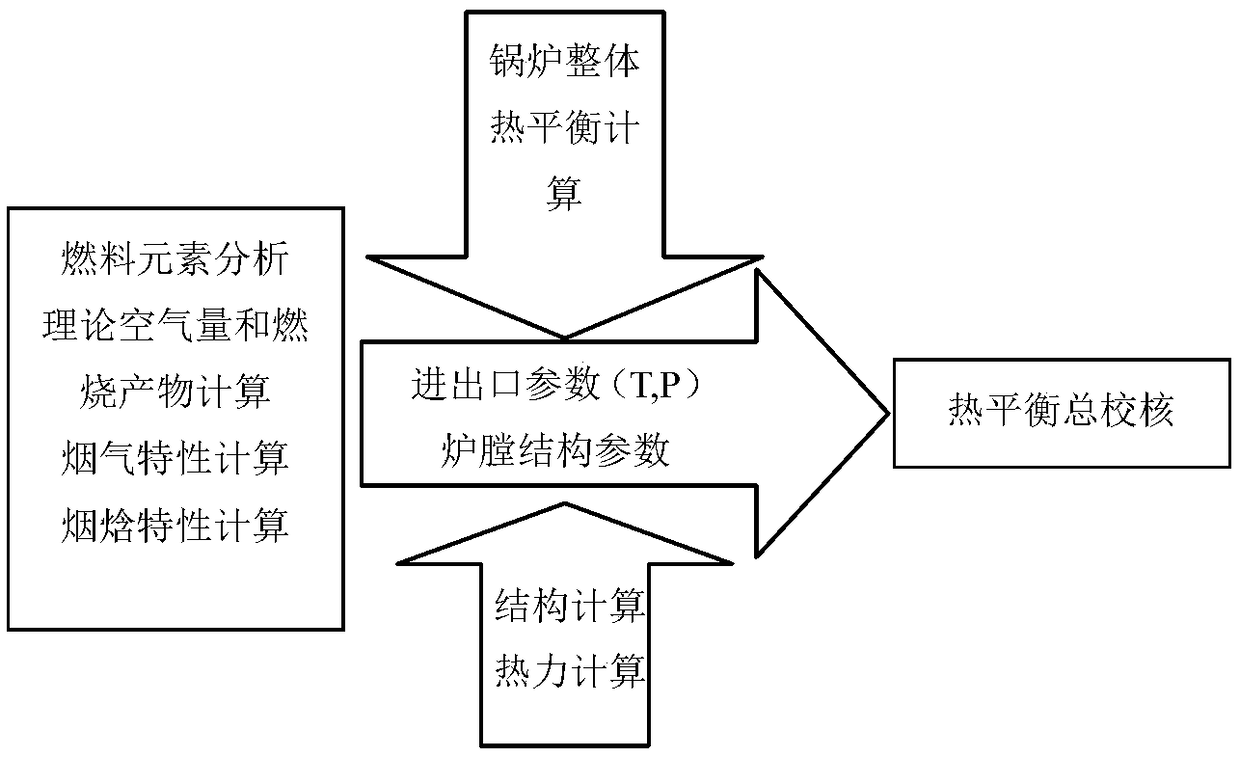

[0032] Such as figure 1 Shown is the physical model of the thermal calculation of the Claus furnace, including all the calculation content. In this embodiment, a complete set of thermal calculation method suitable for the Claus furnace includes the following steps:

[0033] Step 1: First, calculate the thermophysical properties of the Claus furnace fuel. The fuel of the Claus furnace mainly includes gas and acid gas. The combustion of gas plays the role of furnace preheating, and the subsequent working conditions are mainly acid gas. Combustion; based on the assumption of complete reaction of acid gas, analysis of acid gas composition (mol%): H 2 O accounted for 6.96%, CO 2 41.58%, COS 0.01%, H 2 S accounted for 58.68%, CH 4 0.22%, CH 4 S accounts for 0.01%. Among them, methanol sulfur and hydroxyl sulfur are small in content, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com