A fuel cell stack system and starting method

A fuel cell stack and valve body technology, which is applied to fuel cells, fuel cell groups, circuits, etc., can solve the problems of poor infrared characteristics, uneven temperature rise, and low energy utilization rate of the system, and achieve good infrared characteristics and temperature rise. Uniform, simple scheme effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

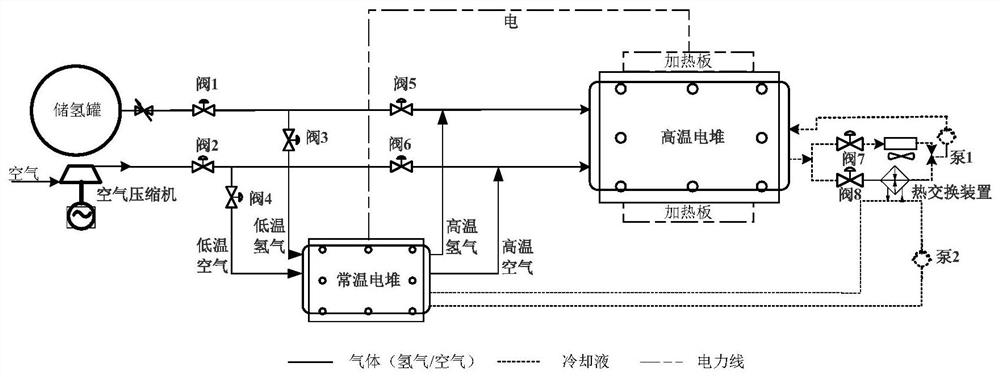

[0055] During the start-up process of the high-temperature stack, open valve 1, valve 2, valve 3, and valve 4, and close valve 5 and valve 6, so that low-temperature hydrogen and low-temperature air first pass through the normal-temperature stack reaction. The working temperature of the normal-temperature stack is low, and the starting performance is good. After the hydrogen and air react in the normal-temperature stack, the high-temperature stack is heated in the following three ways: (1) Inside the normal-temperature stack, hydrogen reacts electrochemically with the air to output electric energy , supplied to the electric heating plate installed inside and at the end of the high-temperature stack, and the high-temperature stack is heated through the resistance thermal effect; (2) The excess coefficient of hydrogen and air passing through the inside of the normal-temperature stack is large, and after the reaction, the electrochemical reaction The heat generated will heat the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com