Husking machine for oil sunflowers

A technology of shelling machine and oil sunflower, which is applied in the direction of shelling, fat oil/fat production, fat production, etc. It can solve the problems of large equipment occupation area, poor shelling effect, low shelling rate, etc., and achieve low cost, The effect of high peeling rate and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

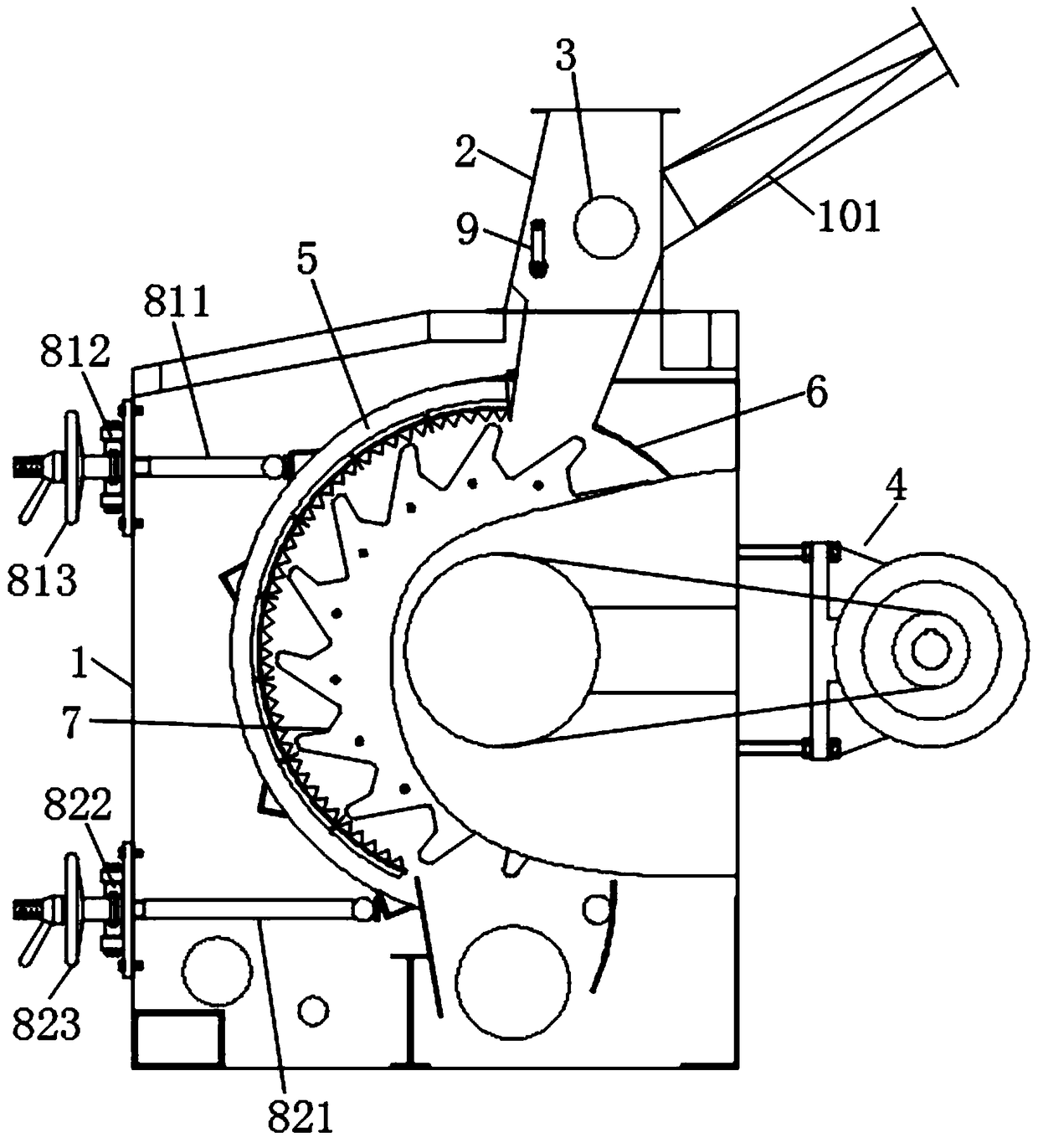

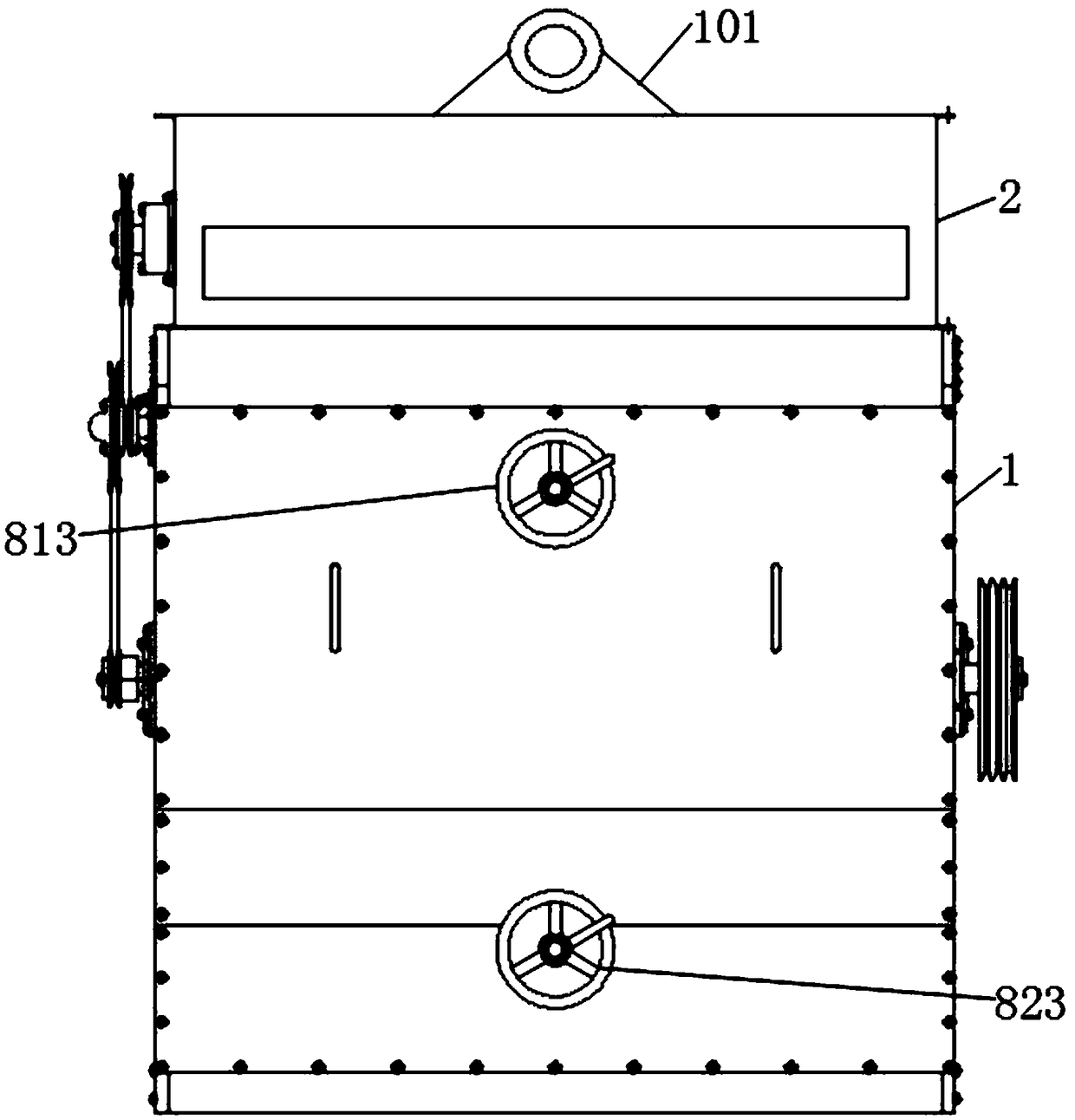

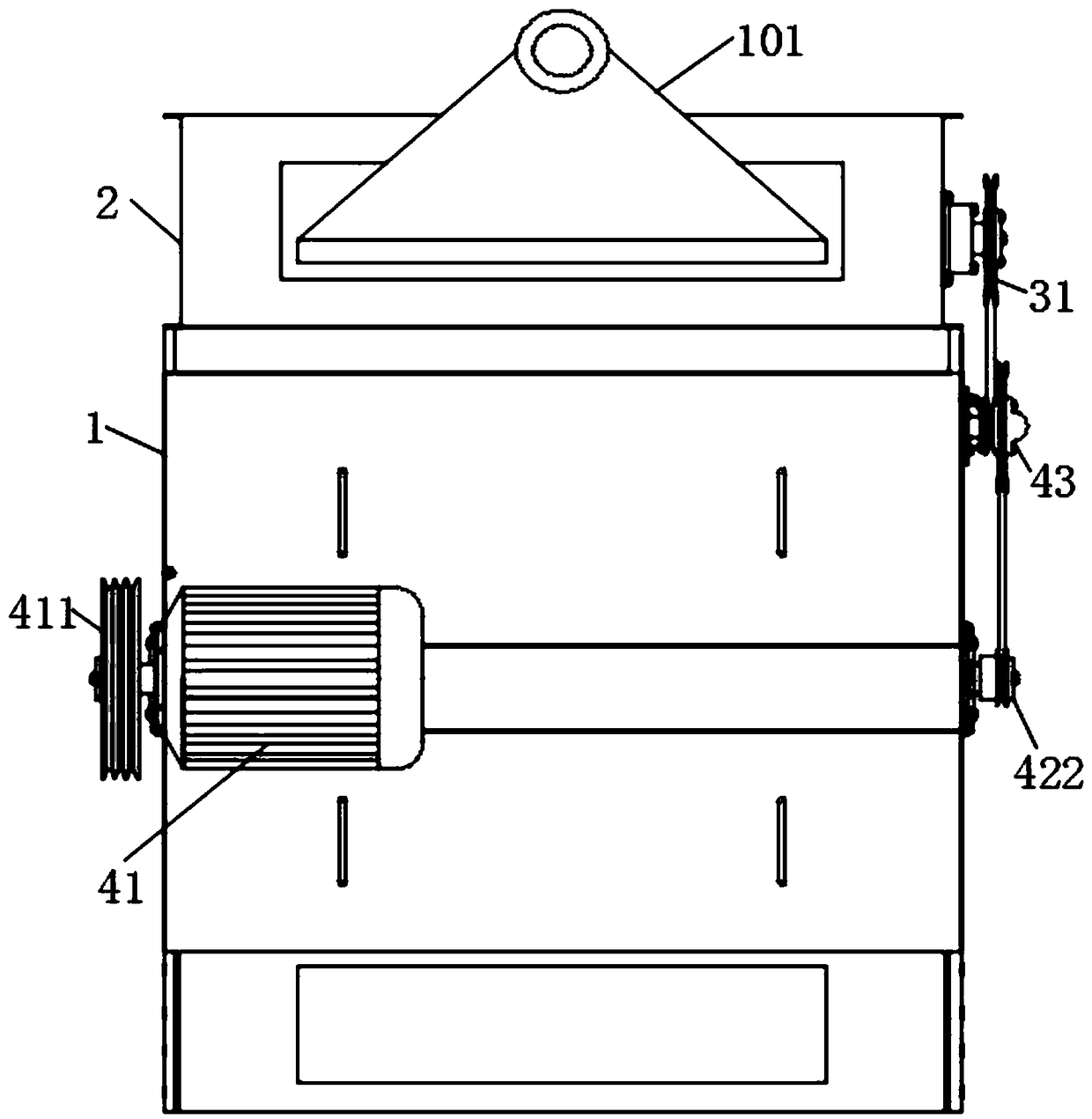

[0037] Example: such as Figures 1 to 4 As shown, the oil sunflower peeling machine of the present embodiment includes a cabinet 1, a feeding hopper 2, a feeding adjustment mechanism 3, a driving mechanism 4, and a centrifugal beating plate 7;

[0038] The top of the above-mentioned chassis 1 is provided with a feeding port, and the feeding port of the above-mentioned feeding hopper 2 is connected and communicated with the above-mentioned feeding port, and the above-mentioned feeding adjustment mechanism 3 is arranged in the above-mentioned feeding hopper 2 to evenly feed materials to the above-mentioned feeding port;

[0039] The interior of the above-mentioned cabinet 1 is located below the above-mentioned feeding port, and a cylindrical peeling chamber extending to both ends is horizontally provided. mouth, the inner wall of one side of the above-mentioned shelling chamber is set as a tooth surface;

[0040] The above-mentioned centrifugal beating plate 7 is a cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com