Control method of cooking utensil

A technology for cooking utensils and control methods, which is applied to cooking utensil lids, cooking utensils, timing control ignition mechanisms, etc., can solve the problems of long overall cooking time, long waiting time for opening the lid, and inability to judge the normal operation of the air pump, etc. The effect of heating waiting time, shortening cooking time, and preventing overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

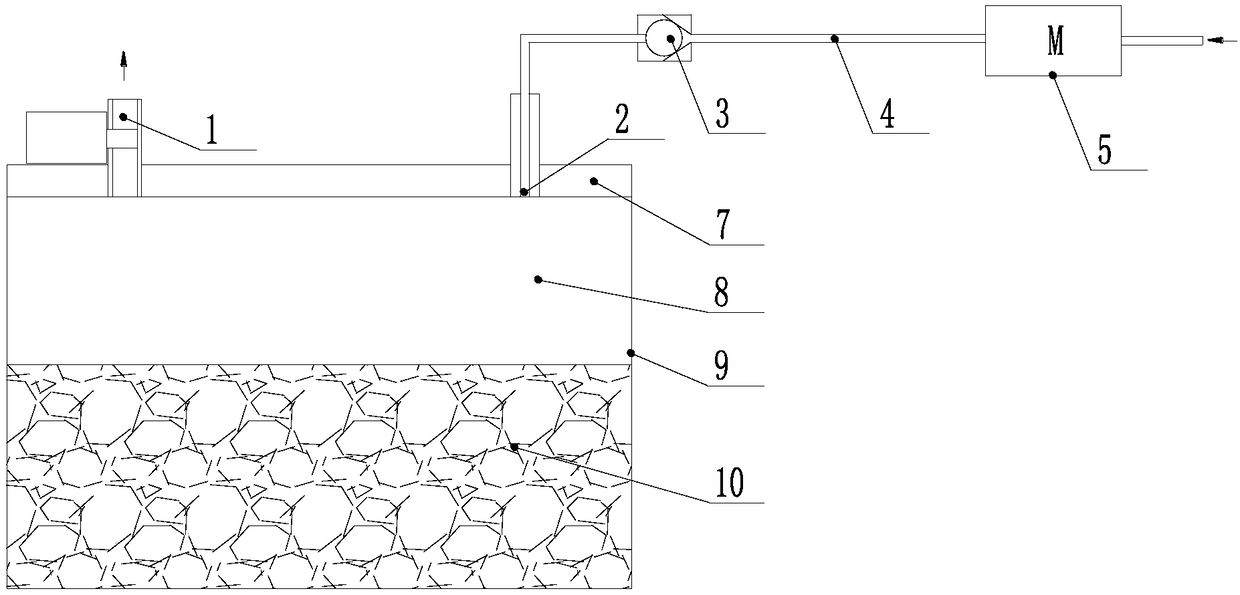

[0053] The cooking appliance of the first embodiment is an electric pressure cooker, figure 1 Shows the working schematic diagram of the electric pressure cooker for quick porridge cooking. The cooking appliance of the first embodiment includes an inner pot 9, a cooking cavity 8 is formed in the inner pot 9, and food materials 10 are contained in the cooking cavity 8. The electric pressure cooker also includes an exhaust port 1, a pressure limiting valve, an air intake port 2, a one-way valve 3, an air intake channel 4, an air pump 5, a pot cover 7 and a heating device. The air inlet 2 and the air outlet 1 are both arranged on the pot cover 7. The heating device is used for heating the cooking cavity. The aforementioned pressure limiting valve is also called an exhaust valve.

[0054] The air pump 5 is arranged on the air intake channel 4 to draw air outside the cooking appliance into the cooking cavity. The exhaust port 1 is provided with a pressure limiting valve, and the ex...

Embodiment 2

[0067] The working principle of the second embodiment is as follows:

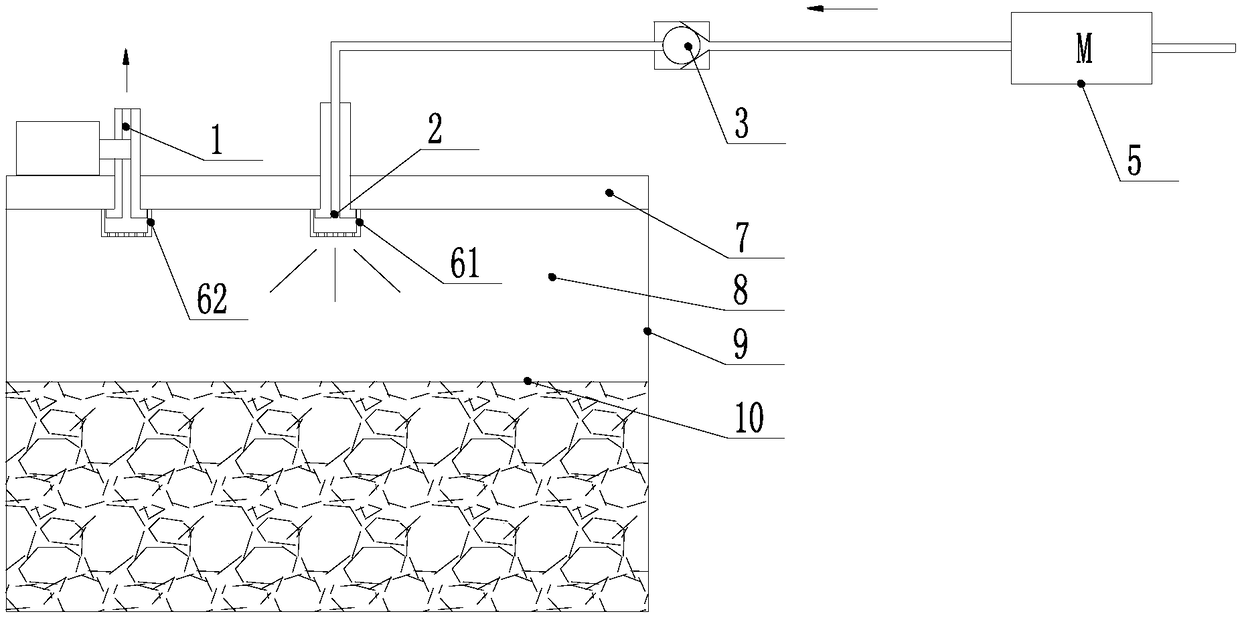

[0068] When the ingredients 10 are cooked in the closed cooking cavity 8 composed of the pot cover 7 and the inner pot 9, and the air pump 5 adds cold air to the closed cavity through the one-way valve 3, the air intake from the air inlet 2 passes through the air inlet cap 61 sprays the intake air to the surface of the food material 10 in the inner pot 9 so that the largest area has a cooling effect and reduces foam generation and overflow. At the same time, at the end of the discharge and the cooking process, the foam generated on the surface of the food material 10 cannot easily enter the air inlet 2 and the air outlet 1, thereby reducing the risk of overflow and facilitating cleaning.

[0069] Since the air intake cap 61 is provided at the air inlet as a guide part, the guide part disperses and / or changes the direction of the airflow at the air inlet, so the guide part can disperse the air intake above the fo...

Embodiment 4

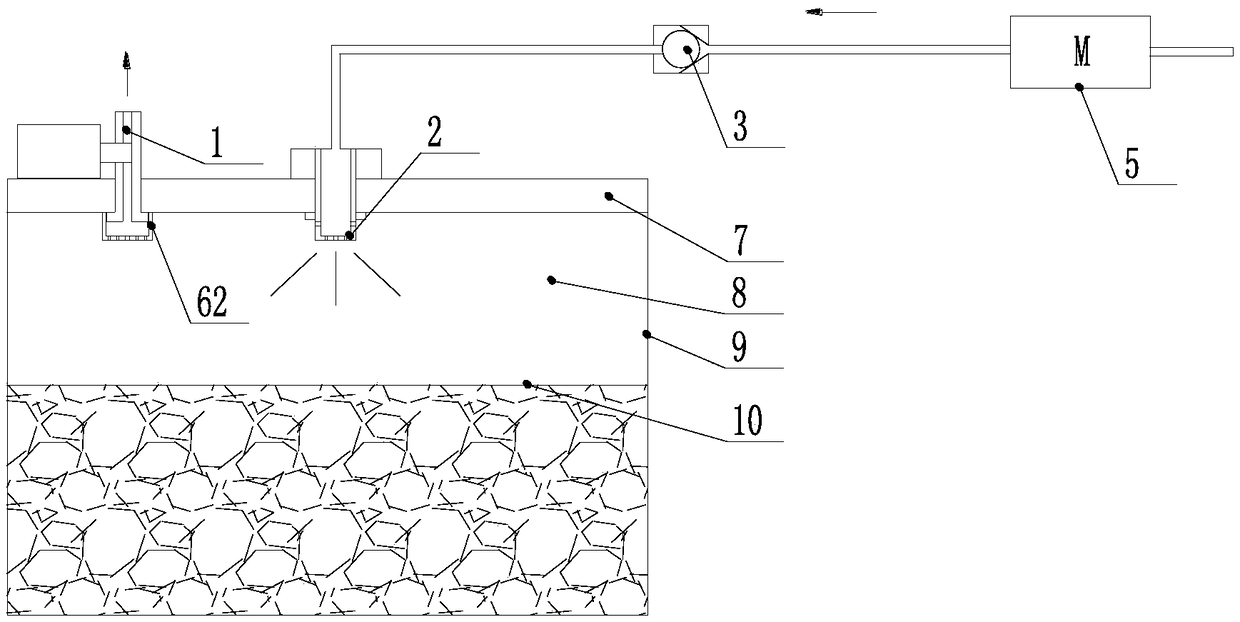

[0074] The cooking appliance of the fourth embodiment is also an electric pressure cooker, which facilitates the frequent removal and cleaning of the inner lid of the lid 7. The one-way valve 3 is arranged at the communication point between the air intake passage 4 and the cooking cavity. The one-way valve 3 of the fourth embodiment is arranged at a separable position of the inner cover, which can be cleaned and prevents the food material in the inner cavity of the electric pressure cooker from entering the air inlet channel 4.

[0075] The electric pressure cooker of the fourth embodiment includes an inner pot 9, a cooking cavity 8 is formed in the inner pot 9, and food materials 10 are contained in the cooking cavity 8. The electric pressure cooker also includes an exhaust port 1, an intake port 2, a one-way valve 3, an intake passage 4, an air pump 5, an intake cap 61, an exhaust cap 62 and a pot cover 7. A pressure limiting valve is installed at the exhaust port 1.

[0076] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com