Packing opening structure adopted in machining process

A technology of mechanical processing and stuffing port, applied in shrimp/lobster processing, grain processing, etc., can solve problems such as poor functionality, single structure of feeding port, pale feeding port, etc., and achieve the effect of improving functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

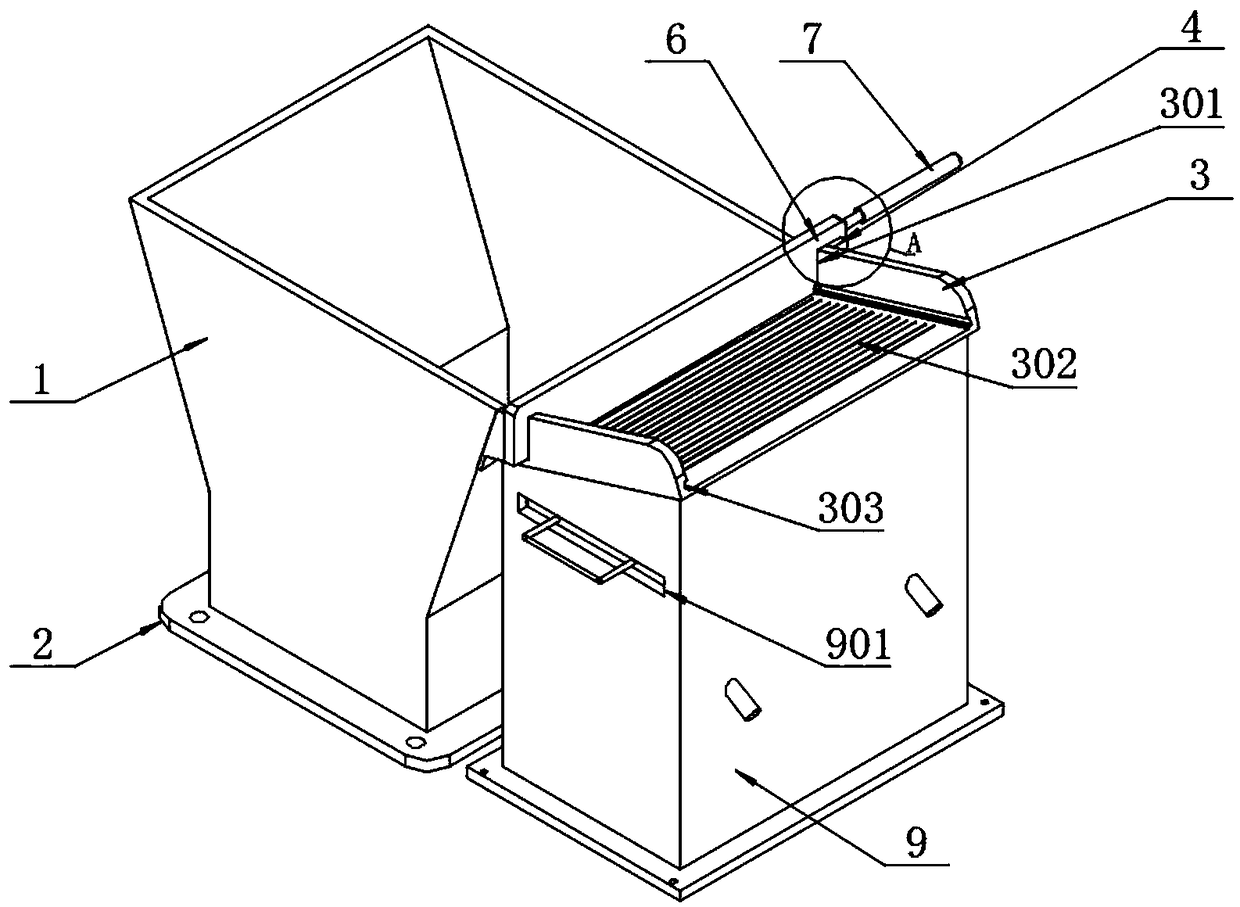

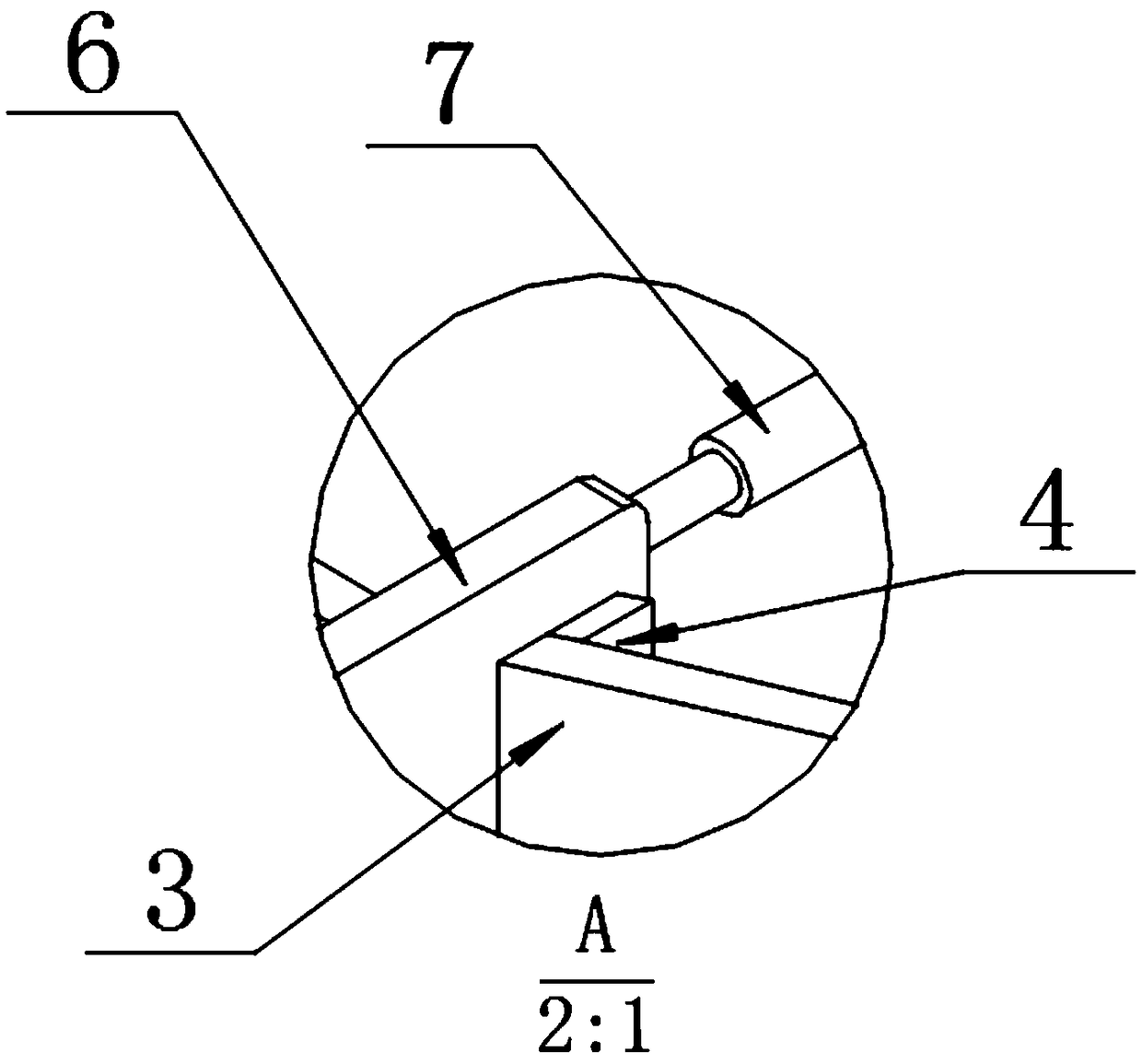

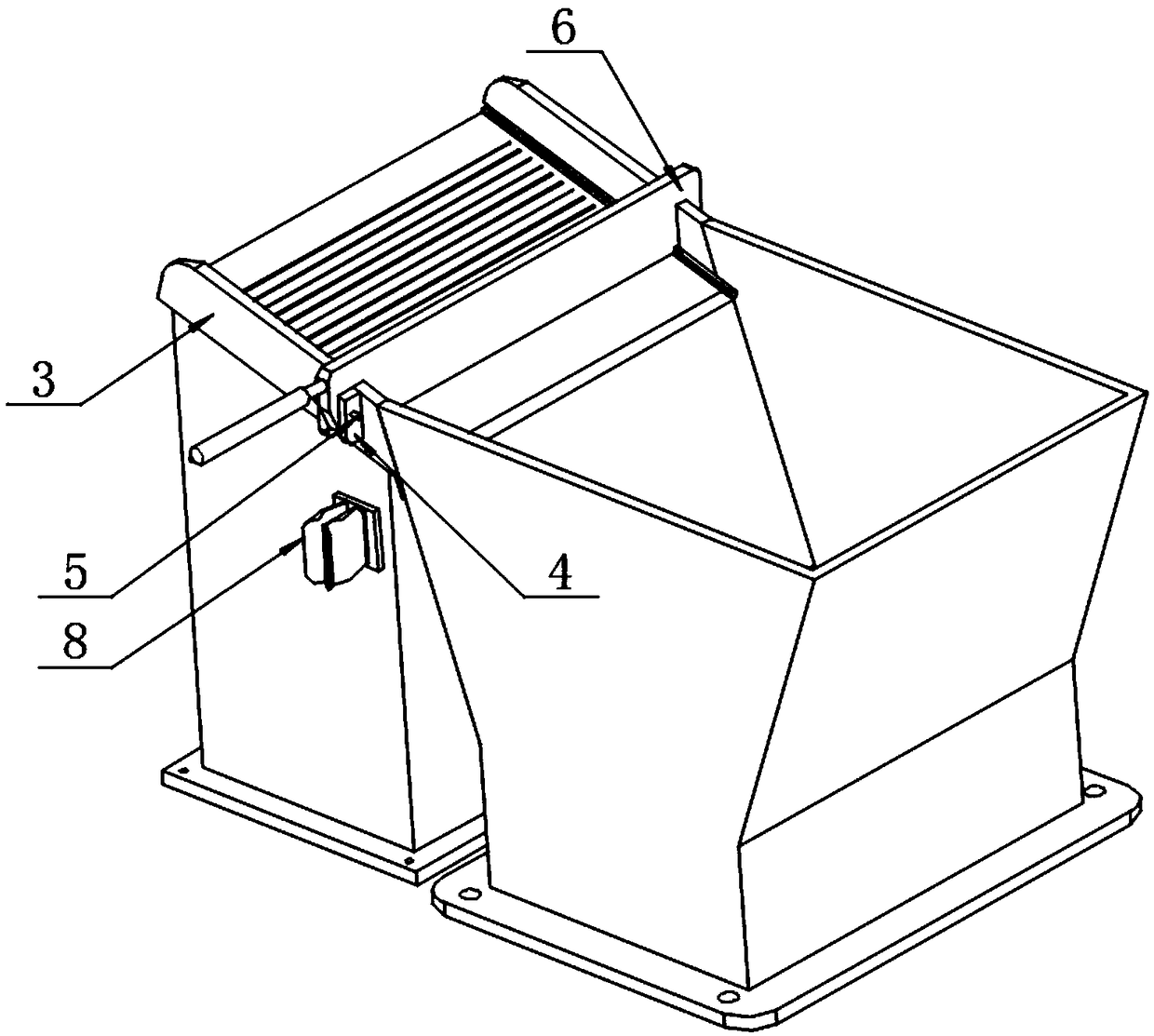

[0031] as attached figure 1 To attach Figure 8 Shown:

[0032] The invention provides a filling port structure in the process of mechanical processing, which includes: a feeding port 1, a mounting ring 2, a filling groove 3, a turning groove 301, a drain groove 302, a slot 303, a rotating plate 4, a rotating shaft 5, Baffle plate 6, trigger lever 7, pressure seat 8, support pipe 9, hand pull groove 901, support seat 10, sewage pipe 11, sewage collection cabin 12, filter seat 13 and pull rod 14; the bottom end of the feed inlet 1 There is a ring of installation ring 2 with installation holes for fixed connection with the feed place of mechanical equipment, and a filling groove 3 with a bracket structure is connected to the right side of the top opening of feed inlet 1 by oblique welding; The rotating plate 4 is two pieces, they are all welded on the rear end surface of the filling groove 3, and through the cooperation of the two filling grooves 3 and the rotating shaft 5, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com