Insulator cleaning device and method

A technology for cleaning devices and insulators, applied in cleaning methods and utensils, cleaning methods using gas flow, chemical instruments and methods, etc., can solve the problems of large space occupation, insignificant cleaning effect, collision of insulator bodies, etc., and achieves practicability Strong, high industrial application value, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0031] Embodiments of the present invention provide an insulator cleaning device and method.

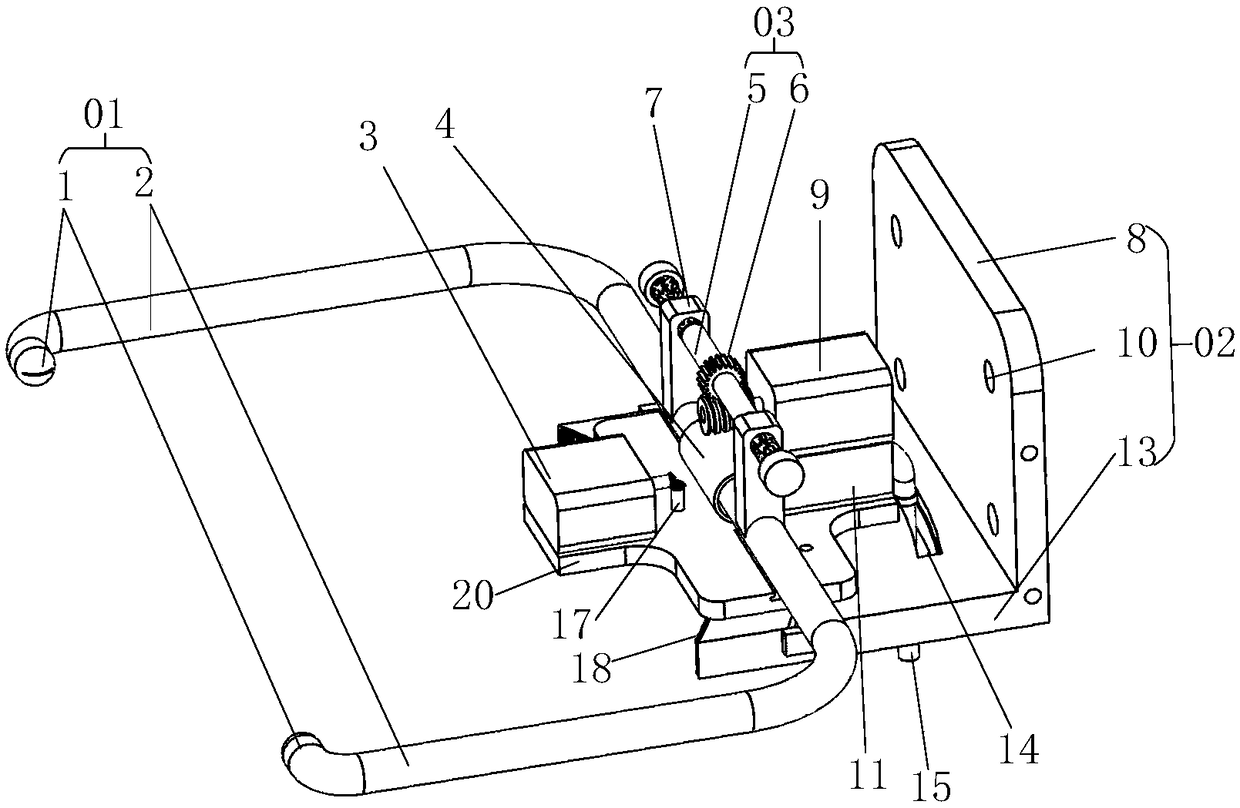

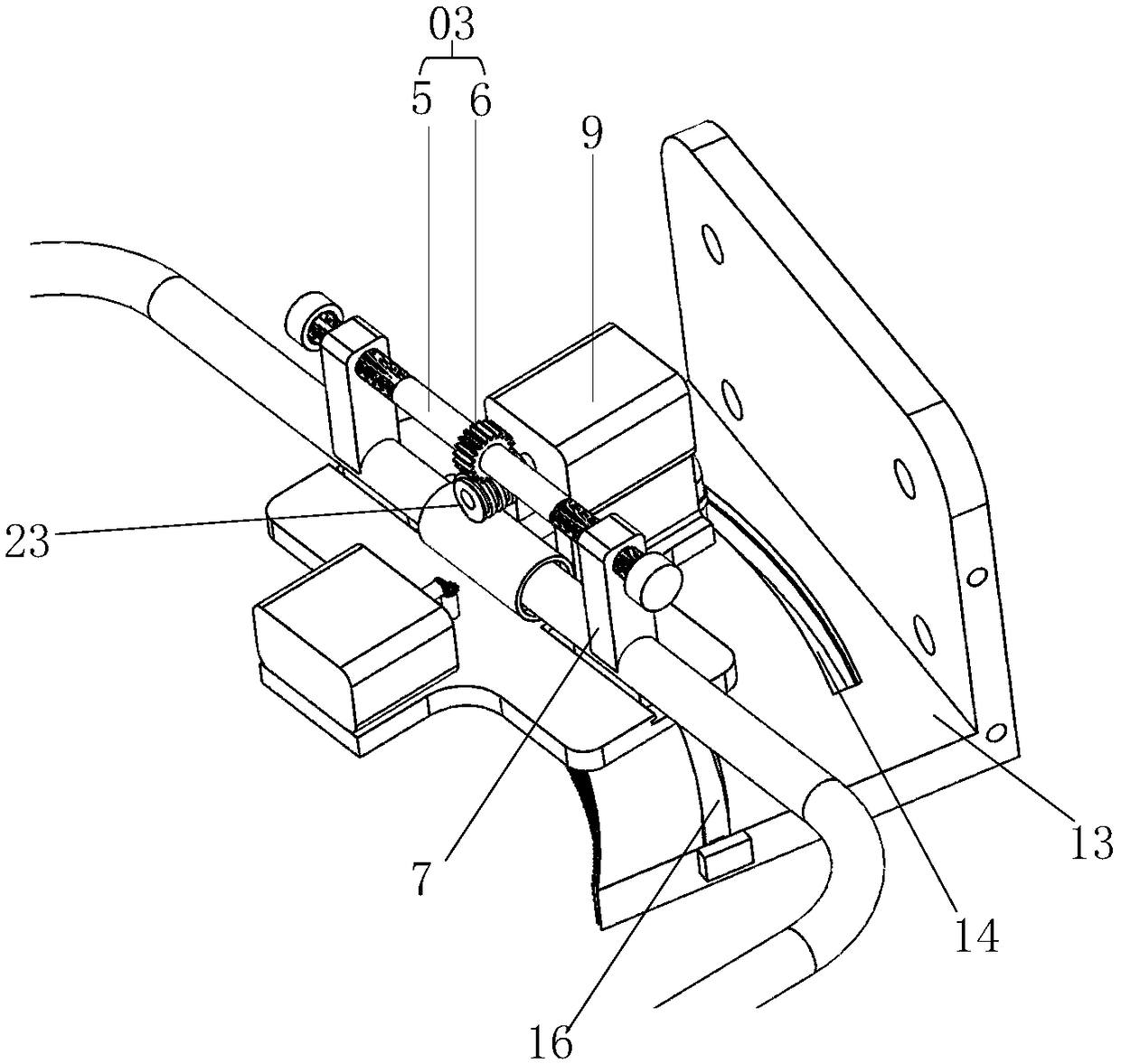

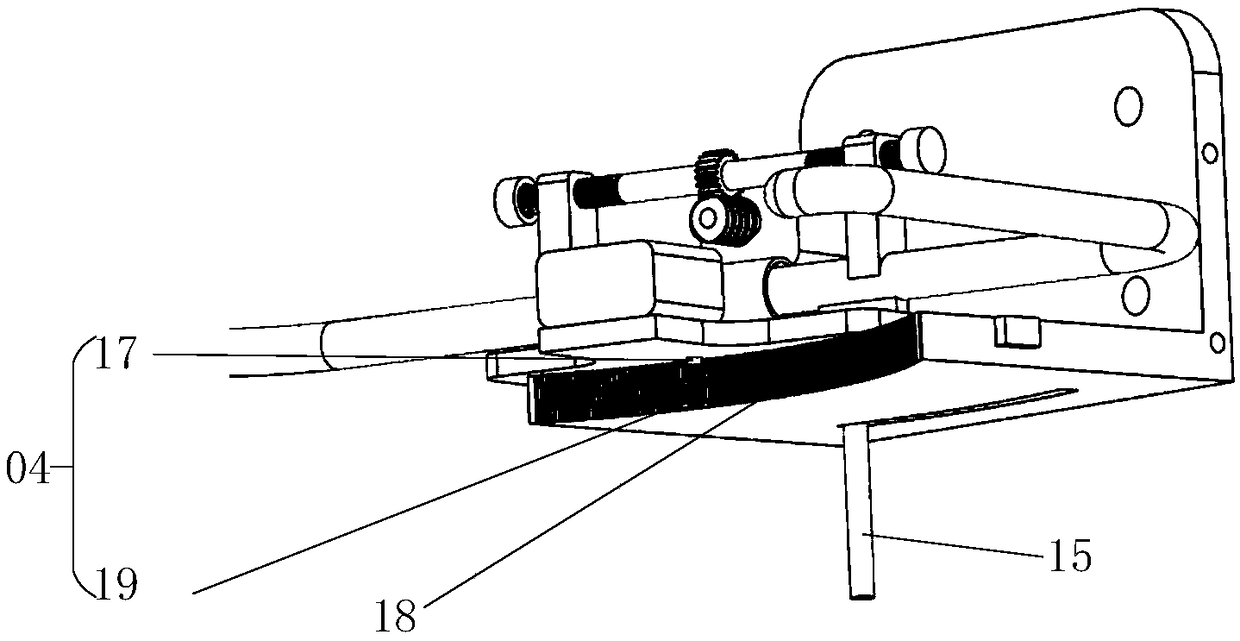

[0032] Please refer to figure 1 , figure 1 It is a schematic diagram of the hardware of the insulator cleaning device in the embodiment of the present invention, including: cleaning mechanism 01, base 02, first transmission mechanism 03, second transmission mechanism 04, first motor 9, second motor 3, telescopic tube 4, two A fixed frame 7, a solenoid valve 11, a motor fixing plate 20, a rotating rack 18 and an air inlet connecting pipe 15.

[0033] The cleaning mechanism 01 includes: two relatively high-pressure linear nozzles 1, two L-shaped hollow tubes 2, one end of the two L-shaped hollow tubes 2 is respectively provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com