Refining method of daclatasvir hydrochloride

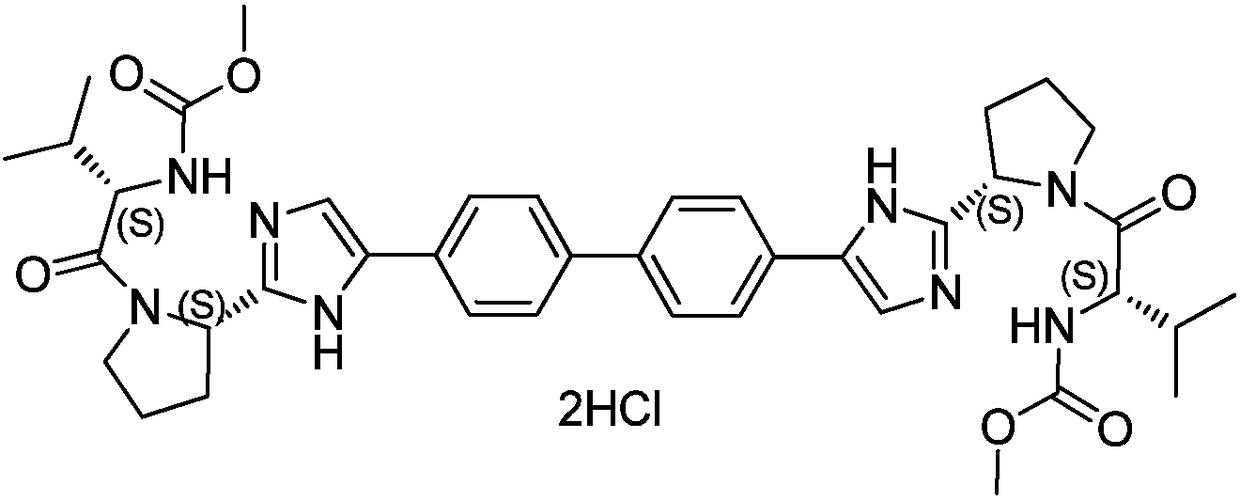

A technology of daclatasvir hydrochloride and refining method, which is applied in the field of medicine and can solve the problems of difficult scale-up production, difficult removal, low yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

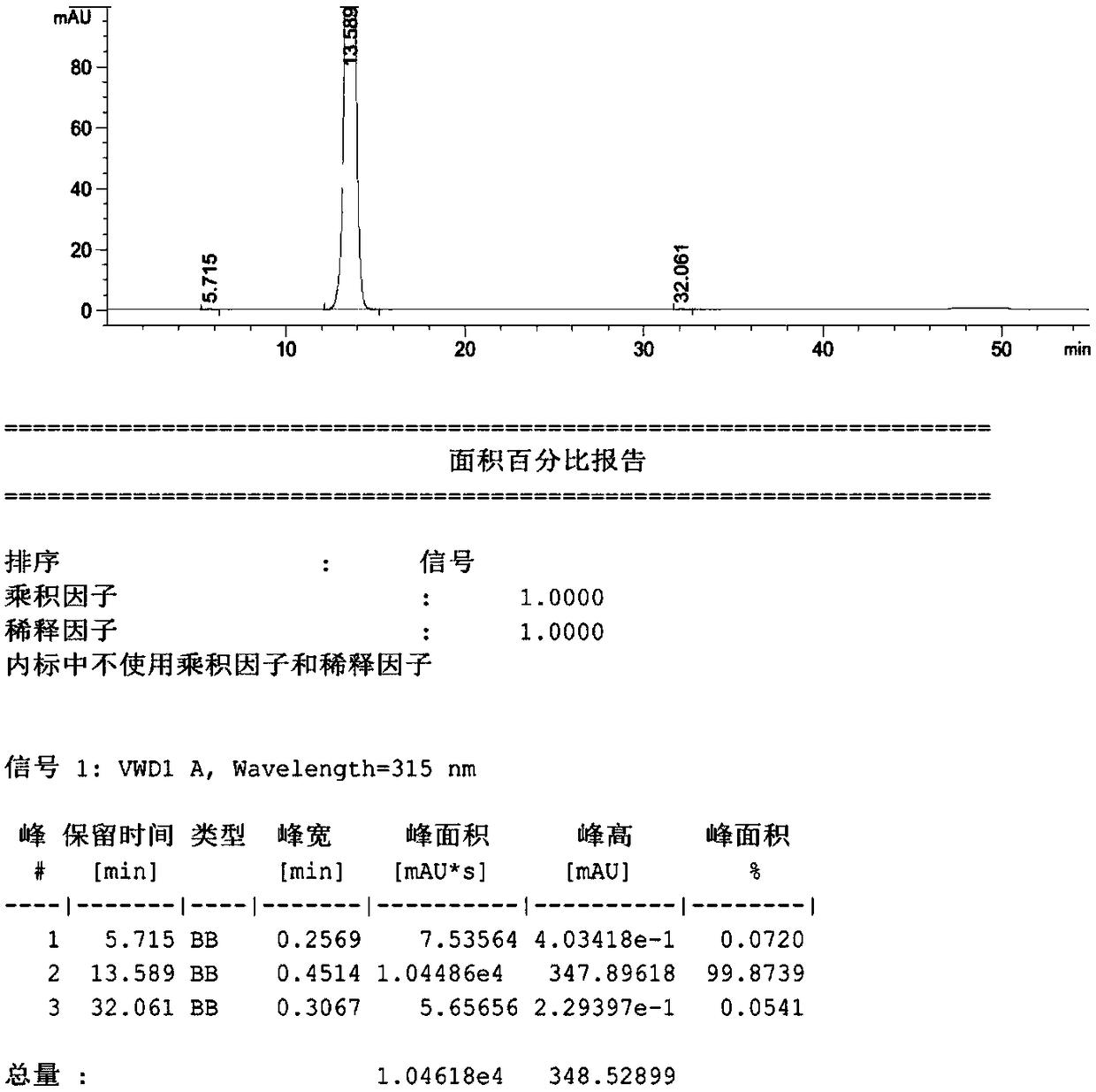

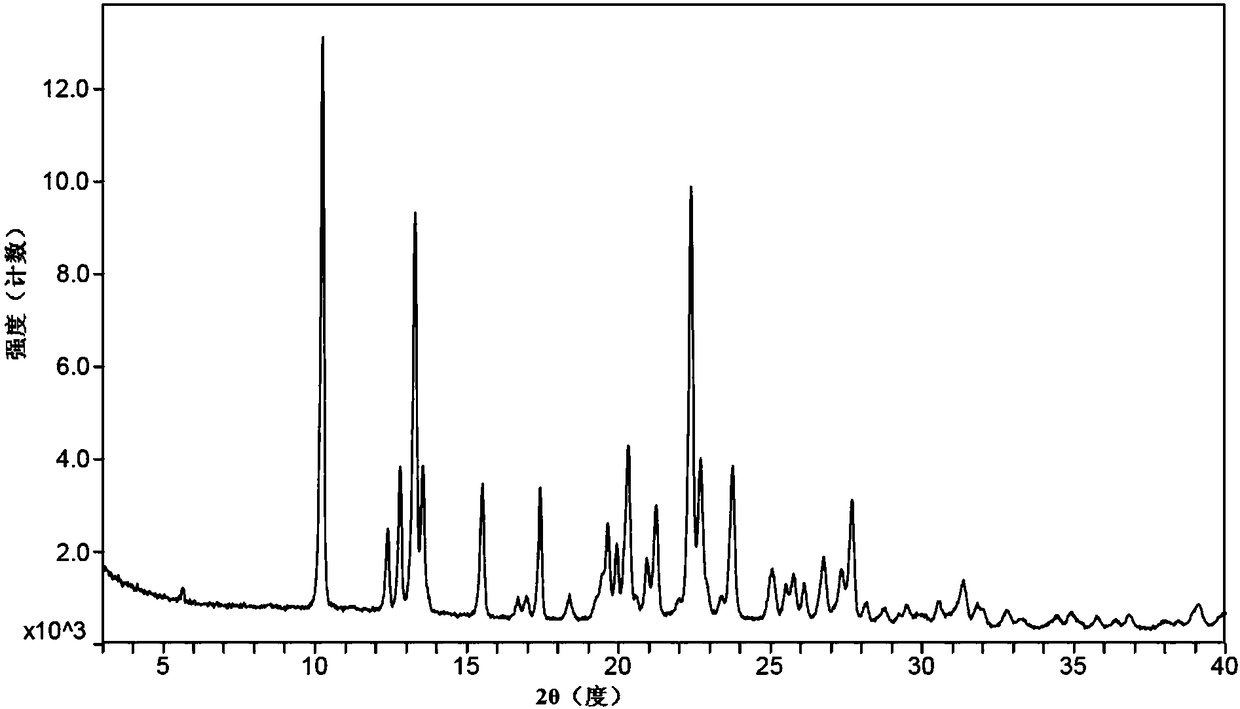

Embodiment 1

[0031] 10 g of crude daclatasvir hydrochloride was dissolved in 45 ml of methanol and stirred at 60°C until dissolved. Add 0.4g of activated carbon, stir at 60°C for 30 minutes, filter while it is hot, add a mixed solvent of 50ml of acetone and 50ml of isopropanol dropwise to crystallize the filtrate when it is heated to 60°C, and crystallize at 20-30°C for 2 hours after the addition is completed, filter , and the filter cake was vacuum-dried at 50° C. to obtain 8.7 g of off-white solid, with a yield of 87%, a chromatographic purity of 99.87%, a maximum heterogeneity of 0.07%, and an isomer of 0.05%.

Embodiment 2

[0033] 10 g of crude daclatasvir hydrochloride was dissolved in 50 ml of methanol and stirred at 58°C until dissolved. Add 0.8g of activated carbon, stir at 65°C for 30 minutes, filter while it is hot, add a mixed solvent of 50ml of acetone and 50ml of isopropanol dropwise to crystallize the filtrate when the temperature is raised to 60°C, and crystallize at 20-30°C for 2 hours after the addition is completed, filter , and the filter cake was vacuum-dried at 50° C. to obtain 8.6 g of a white solid, with a yield of 86%, a chromatographic purity of 99.70%, a maximum heterogeneity of 0.07%, and an isomer of 0.07%.

Embodiment 3

[0035] 10 g of crude daclatasvir hydrochloride was dissolved in 60 ml of methanol and stirred at 55°C until dissolved. Add 0.4g of activated carbon, stir at 65°C for 30 minutes, filter while it is hot, add a mixed solvent of 50ml of isopropanol and 50ml of acetone to crystallize the filtrate when it is heated up to 60°C, and crystallize at 20-30°C for 2 hours after the addition is complete, and filter , and the filter cake was vacuum-dried at 50° C. to obtain 8.5 g of white solid, with a yield of 85%, a chromatographic purity of 99.87%, and a maximum single heterogeneity of 0.07%. Isomers: none.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com