Boron-doped titanium dioxide nanofiber, preparation method for boron-doped titanium dioxide nanofiber and application of boron-doped titanium dioxide nanofiber as anode material of lithium ion battery

A technology of nanofibers and titanium dioxide, which is applied in the direction of secondary batteries, battery electrodes, negative electrodes, etc., can solve the problems of little or no research on doping, and the cycle performance needs to be improved, so as to improve the specific surface area and large specific area. The effect of surface area, favorable wetting and transport of lithium ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

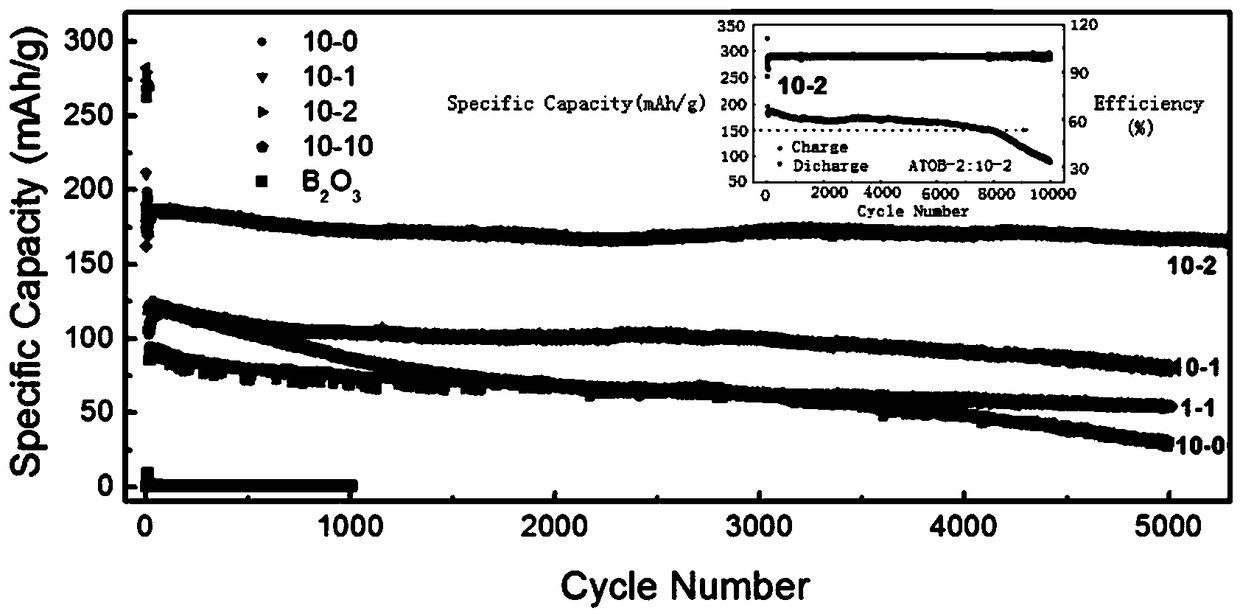

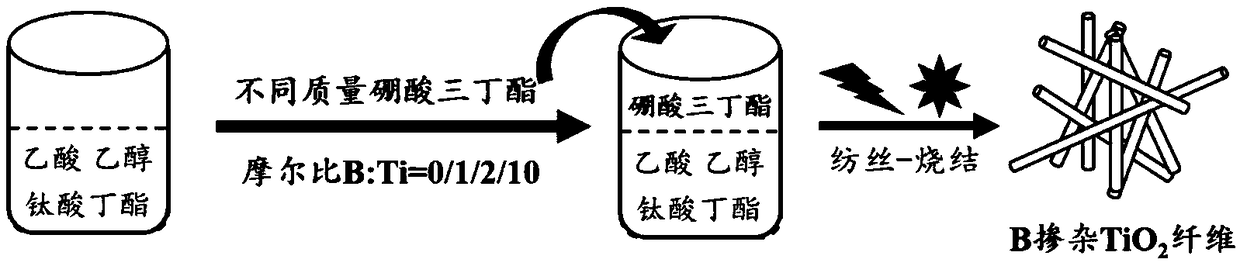

[0041] B-doped TiO according to the present invention 2 The experimental process of the preparation of nanofiber high-rate and long-cycle lithium-ion battery anode materials is as follows: figure 1 shown, including the following steps:

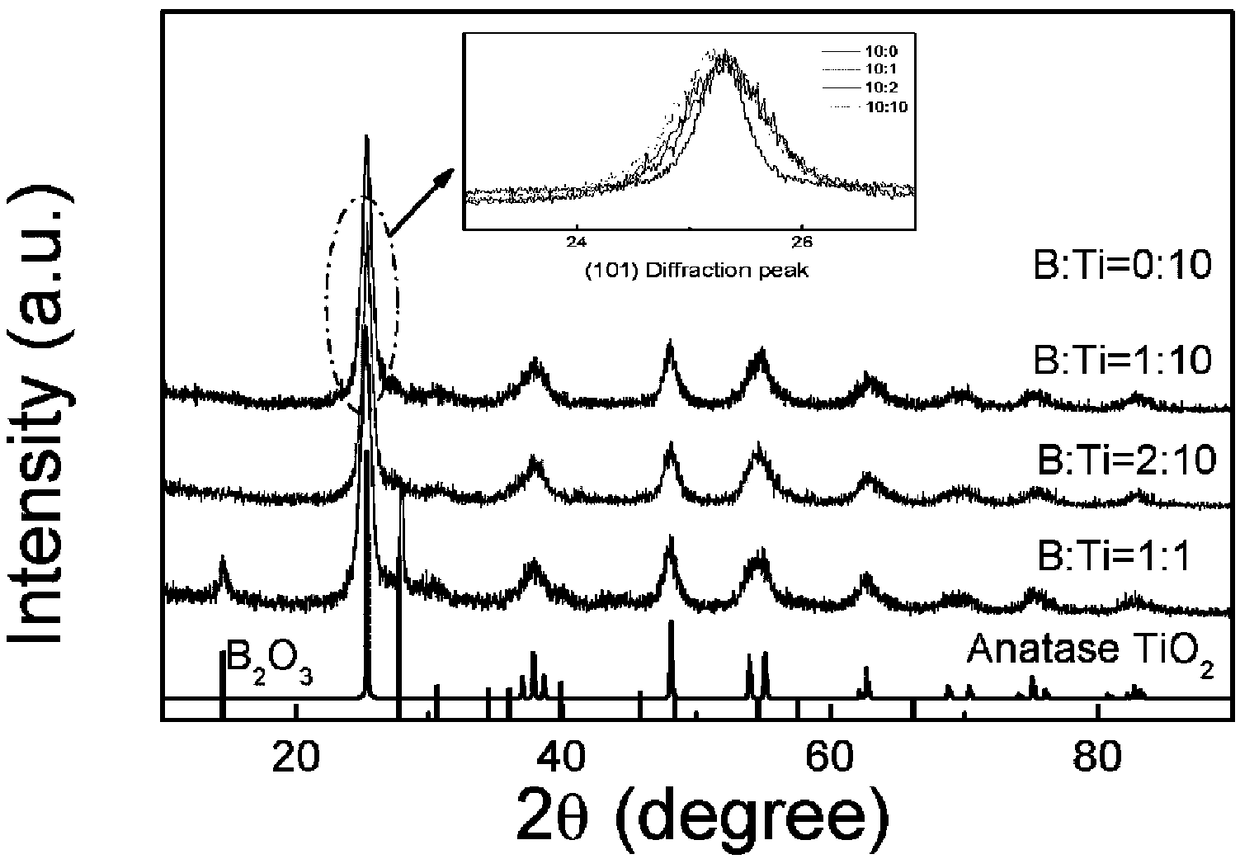

[0042] (1) Mix ethanol, acetic acid, tetrabutyl titanate and tributyl borate uniformly to obtain precursor mixed solution A, wherein the mass ratio of ethanol, acetic acid and tetrabutyl titanate is 10:3:4, wherein titanium The molar ratios to boron are 10:0, 10:1, 10:2, 10:10, respectively.

[0043] (2) Add polyvinylpyrrolidone into precursor liquid A and stir to completely dissolve to obtain a mixed liquid, wherein the ratio of polyvinylpyrrolidone to precursor liquid A is 0.05 g / mL.

[0044] (3) Put the mixed solution in (2) in an electrospinning machine at a temperature of 30° C. and an ambient humidity of 20%, apply a voltage of 19 kV, and spin at a speed of 3 mL / h to obtain nanofibers.

[0045] (4) Dry the polymer nanofibers at 80°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com