A kind of positive electrode active material and preparation method thereof, positive electrode and lithium ion battery

A positive electrode active material, a positive electrode technology, applied in the field of lithium ion battery positive electrode, positive electrode active material and its preparation, can solve the problems of manganese dissolution, poor conductivity, etc., and achieve the effects of reducing manganese dissolution, isolating contact, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present application also proposes a method for preparing a positive electrode active material, which includes: mixing a lithium manganese iron phosphate material with a carbon material attached to the surface and a molybdenum source, and then mixing it under an atmosphere of reducing gas and nitrogen, or under an atmosphere of ammonia. Sintering to obtain the above positive electrode active material. Preferably, the sintering temperature is 500-800° C., and the sintering time is 2-48 hours, so as to further optimize the coating layer. Preferably, the reducing gas is hydrogen. The reducing gas and nitrogen can form a mixed atmosphere, and the manganese iron phosphate lithium material with carbon materials attached to the surface can also be used to mix with the molybdenum source and then pass through the high-temperature reducing gas and nitrogen in turn. The present invention preferably combines the reducing gas and nitrogen to form a mixture Atmosphere: the lithiu...

Embodiment 1

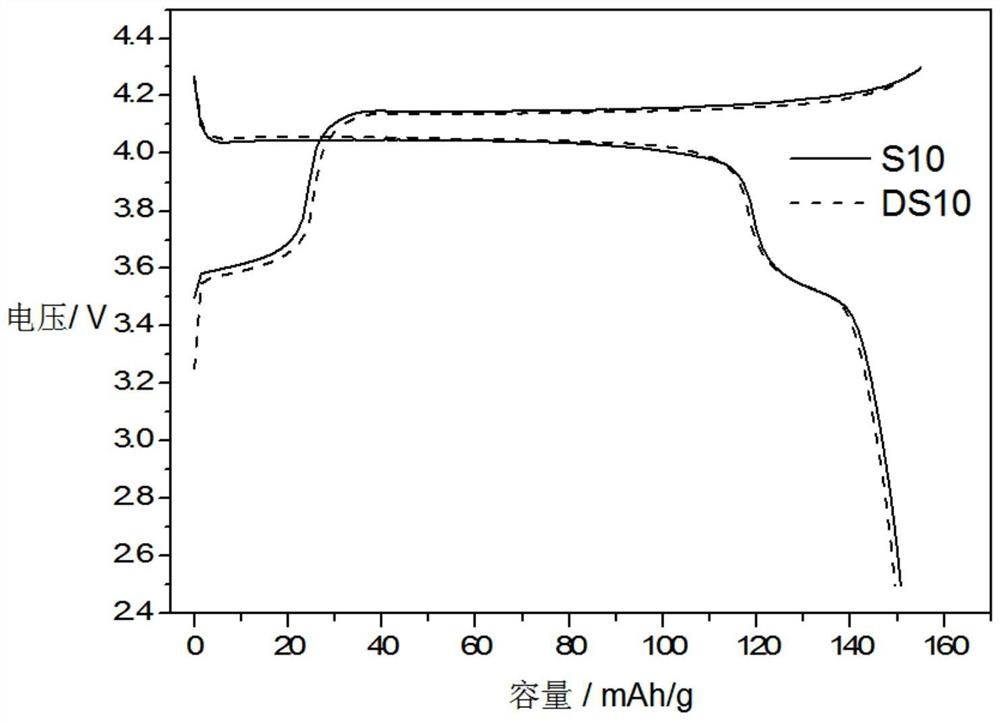

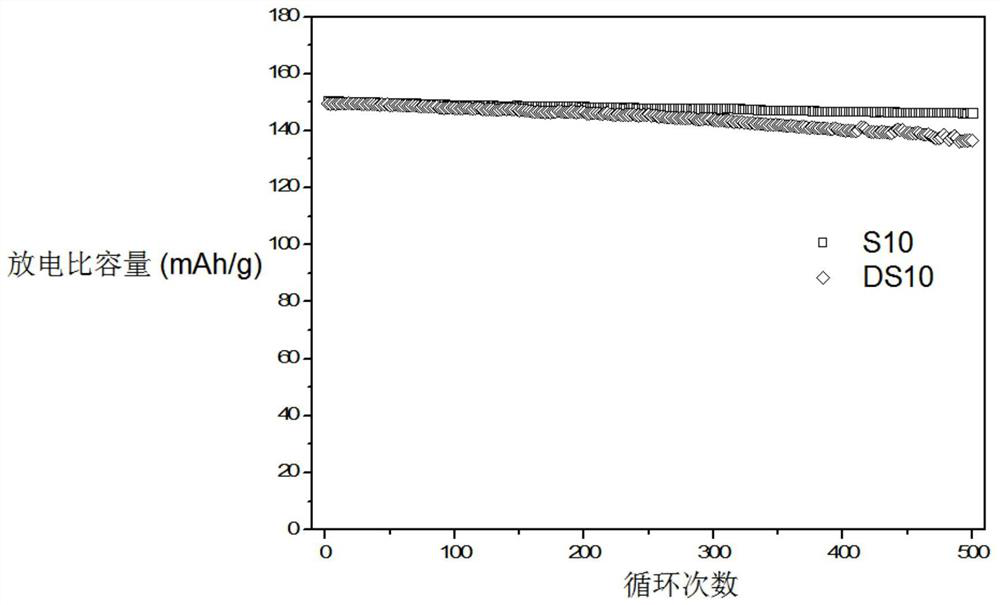

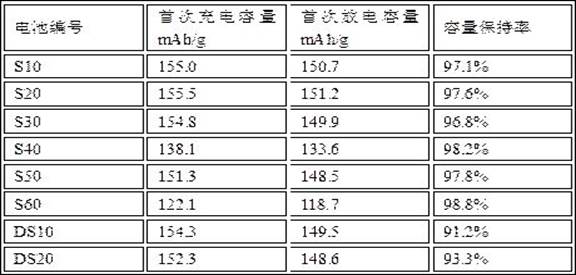

[0028] LiH 2 PO 4 , MnCO 3 , FeC 2 o 4 Mix with glucose according to the molar ratio of 1:0.8:0.2:0.092, place in a stirring ball mill and mix and grind for 8 hours; place the precursor prepared by fully mixing and grinding in a corundum crucible; put the crucible into a tube furnace, and pass through Ar Gas, heating from room temperature, the heating rate is 5 ° C / min, the temperature is raised to 700 ° C for 10 h, and then naturally cooled to room temperature to obtain LiMn 0.8 Fe 0.2 PO 4 / C material. LiMn 0.8 Fe 0.2 PO 4 / C and MoO 3 Mix according to the mass ratio of 96:5.6, place in a stirring ball mill, add ethanol, and wet mix and grind for 6 hours; dry the precursor prepared by fully mixing and grinding and place it in a corundum crucible; put the crucible in a tube furnace, and Into H containing 10% hydrogen by volume 2 / N 2 Mixed gas, heating from room temperature with a heating rate of 5°C / min, raising the temperature to 700°C for 15 hours, and then ...

Embodiment 2

[0030] LiH 2 PO 4 , MnCO 3 , FeC 2 o 4 Mix with glucose according to the molar ratio of 1:0.9:0.1:0.046, place in a stirring ball mill and mix and grind for 8 hours; place the precursor prepared by fully mixing and grinding in a corundum crucible; put the crucible into a tube furnace, and pass Ar Gas, heating from room temperature, the heating rate is 5 ° C / min, the temperature is raised to 700 ° C for 10 h, and then naturally cooled to room temperature to obtain LiMn 0.9 Fe 0.1 PO 4 / C material. LiMn 0.9 Fe 0.1 PO 4 / C and MoCl 5 Mix according to the mass ratio of 95:13.3, add water and stir for 1 hour, then spray dry, and place the obtained powder in a corundum crucible; put the crucible in a tube furnace, feed ammonia gas, and start heating from room temperature at a heating rate of 5°C / min, heated to 550°C for 20h, and then naturally cooled to room temperature to obtain a carbon content of 1wt.%, Mo 2 LiMn with 5wt.% N content 0.9 Fe 0.1 PO 4 / C / Mo 2 N c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap