Disc brake device

A disc brake and suction device technology, applied in the direction of the type of brake, the brake in the axial direction, the components of the brake, etc., can solve the problems of difficult cooling of the disc brake device, unavoidable enlargement of the device, and reduced braking performance. , achieve the effect of suppressing the scattering of wear powder to the surrounding, preventing the increase in size, and preventing the reduction of the braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0161] [the first example of embodiment]

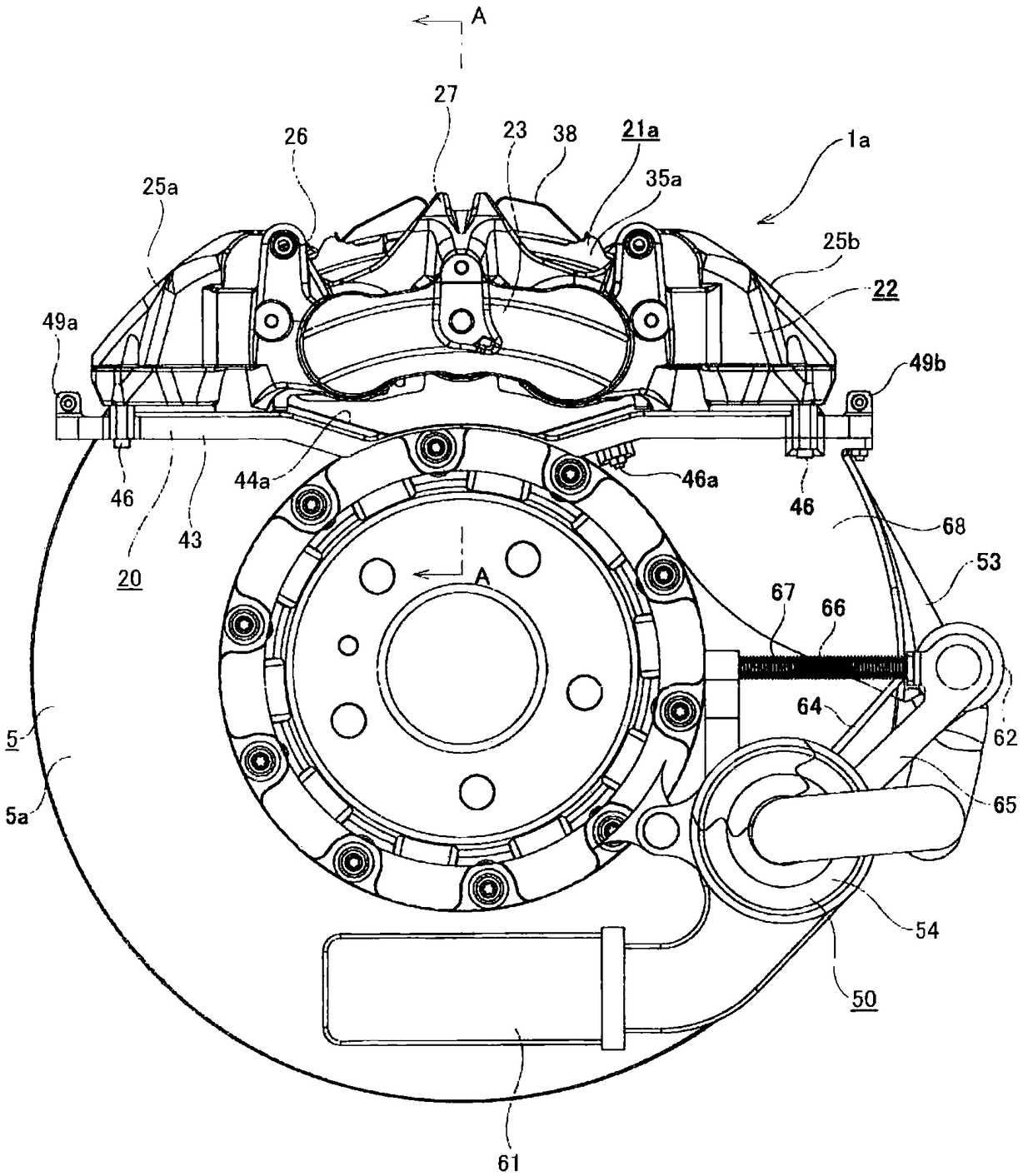

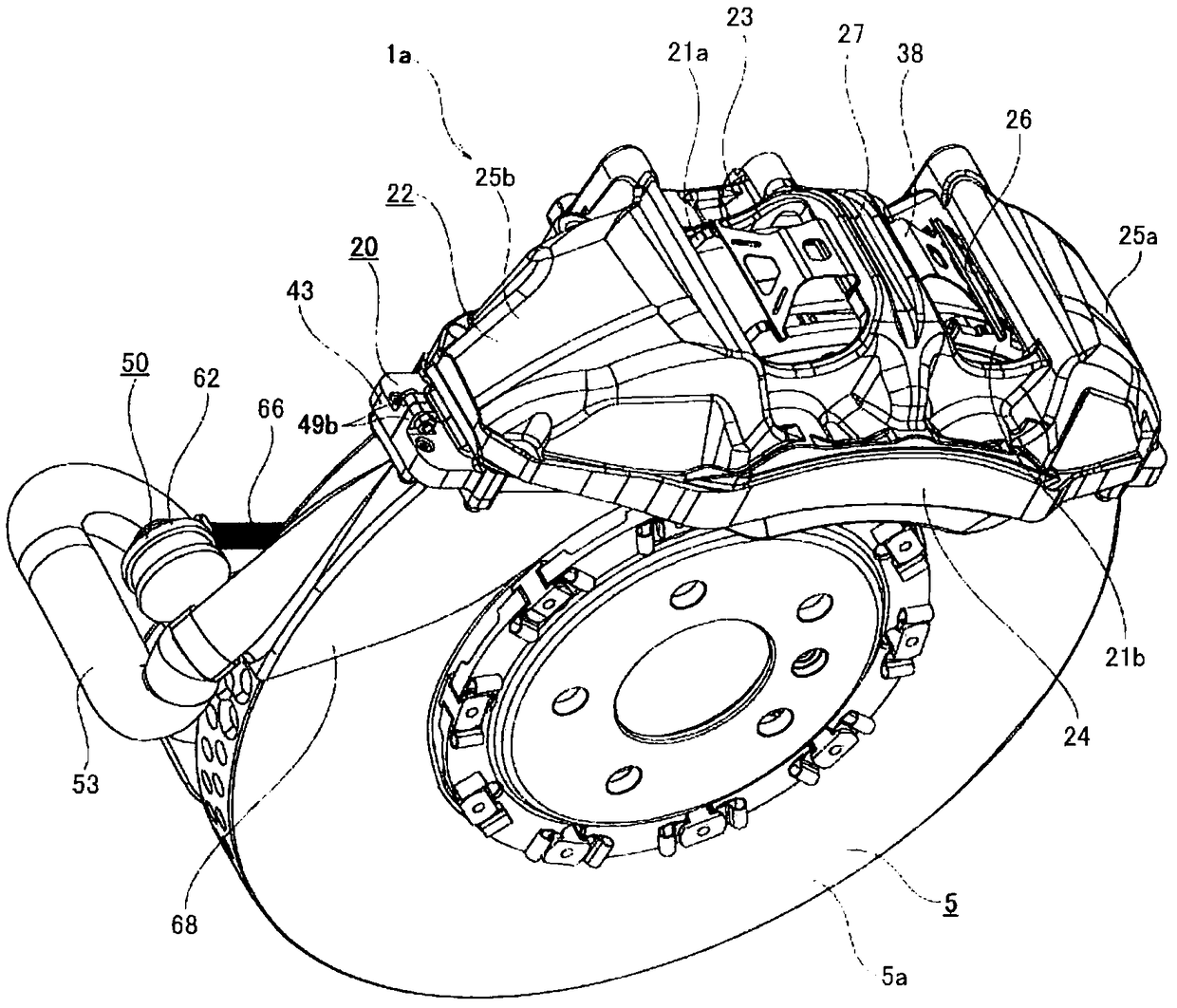

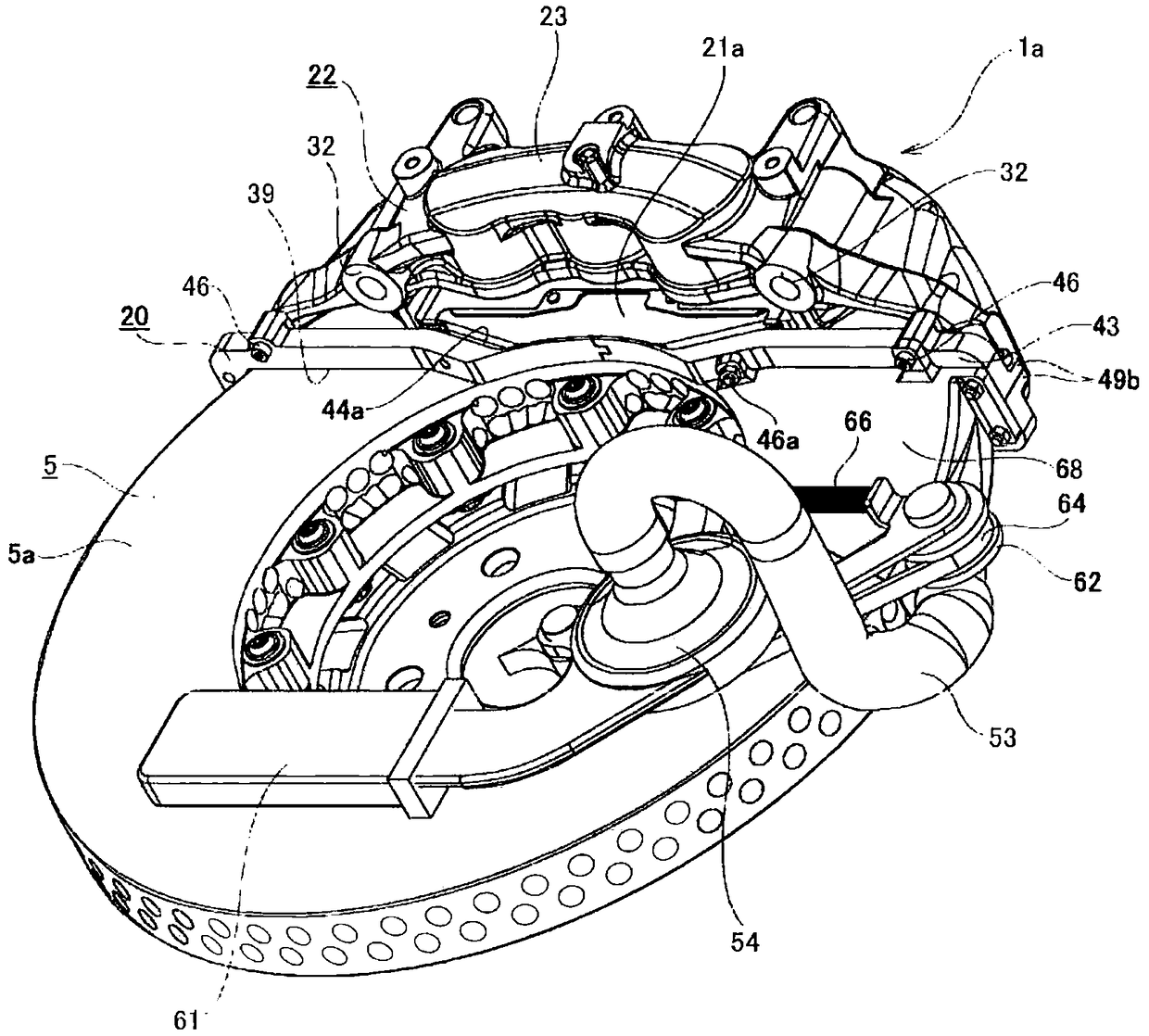

[0162] refer to Figure 1-10 A first example of an embodiment of the present invention will be described. In this first example, a case where an abrasion powder scattering preventing cover 20 is provided in an opposed-piston type disc brake device 1 a for preventing abrasion powder from scattering around the disc brake device 1 a will be described.

[0163] The disk brake device 1a of this first example is arranged axially ( figure 1 The inside and outside direction) clamped on both sides, so as to exert the braking force. In addition, the inner pad 21 a and the outer pad 21 b are axially movable supported by a caliper 22 provided so as to straddle a part of the circumferential direction of the rotor 5 from the radially outer side.

[0164] The caliper 22 is, for example, made of metal such as aluminum alloy, and has: an inner body portion 23 and an outer body portion 24 disposed on both inner and outer sides of the rotor 5; and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com