Distribution system adopting AGV assisting in finding cloth from warehouse

A warehouse and cloth technology, applied in the field of AGV distribution assistance warehouse cloth finding system, can solve the problems of reducing work efficiency, time-consuming and laborious, etc., and achieve the effect of improving work efficiency, reducing manufacturing costs, and ensuring smooth and uninterrupted operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

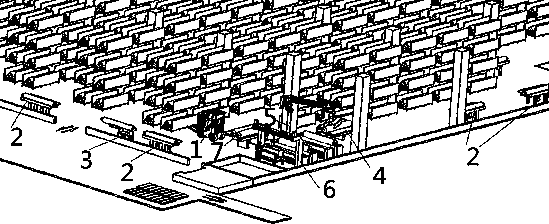

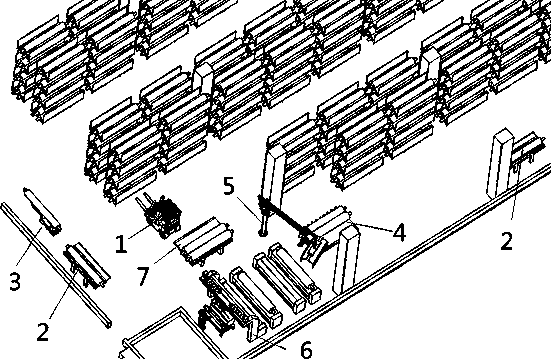

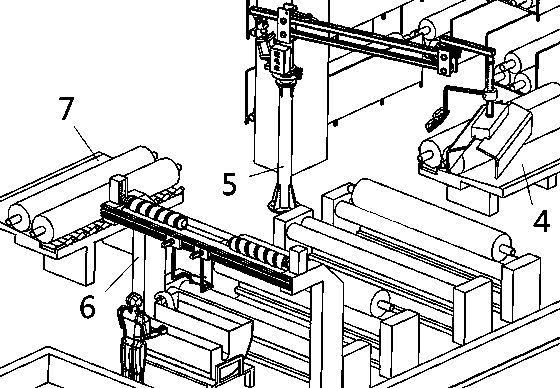

[0020] Figure 1-3 A schematic diagram of the local structure of the AGV distribution assisting warehouse cloth finding system in this embodiment is given respectively Figure 1 , two 3. Combined with reference Figure 1-Figure 3 , an AGV distribution assisting warehouse to find cloth system, used to distribute the cloth from the warehouse shelves to the shearing machine, including forklift 1, several fixed-point temporary cloth storage tables 2, AGV trolley 3, AGV cloth release table 4, clamps 5, opening The shearing machine 6 and the recycling cloth table 7, wherein, each fixed-point temporary cloth storage table 2 is respectively arranged in the row and column of the corresponding warehouse shelf, and is used for temporarily placing the cloth transported by the forklift 1 from the warehouse shelf, and the forklift 1 is used for placing the cloth Transport from the shelf to the fixed-point temporary cloth storage platform 2; the AGV cloth release platform 4 is set at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com