Shaft end oil seal structure of gearbox

A gearbox and oil seal technology, which is applied to belts/chains/gears, transmission parts, mechanical equipment, etc., can solve problems such as fluid leakage, reduced service life of gears and bearings, economic losses for users, etc., and prevent lubricating oil leakage , reduced shaft end and axial dimension, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

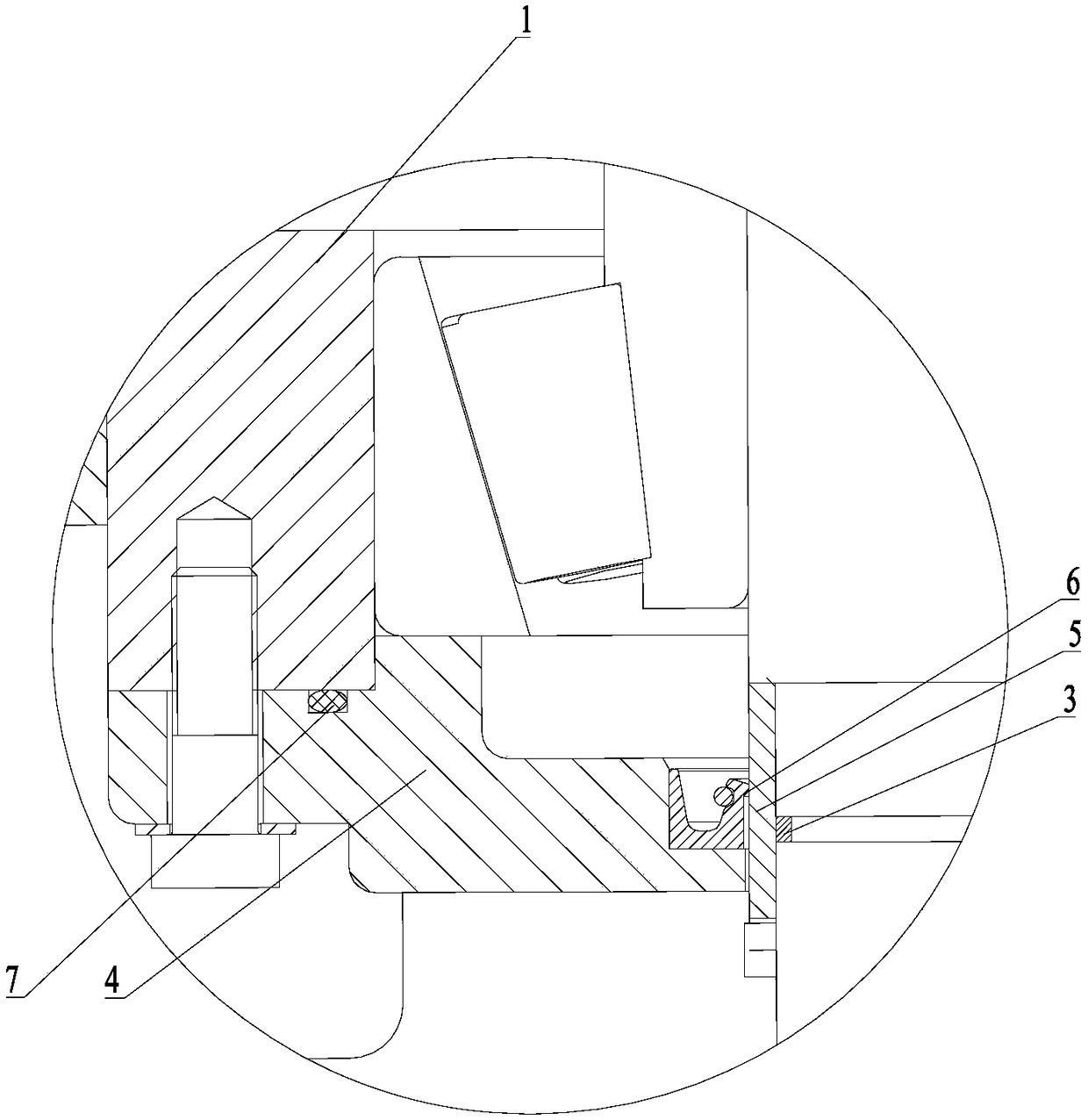

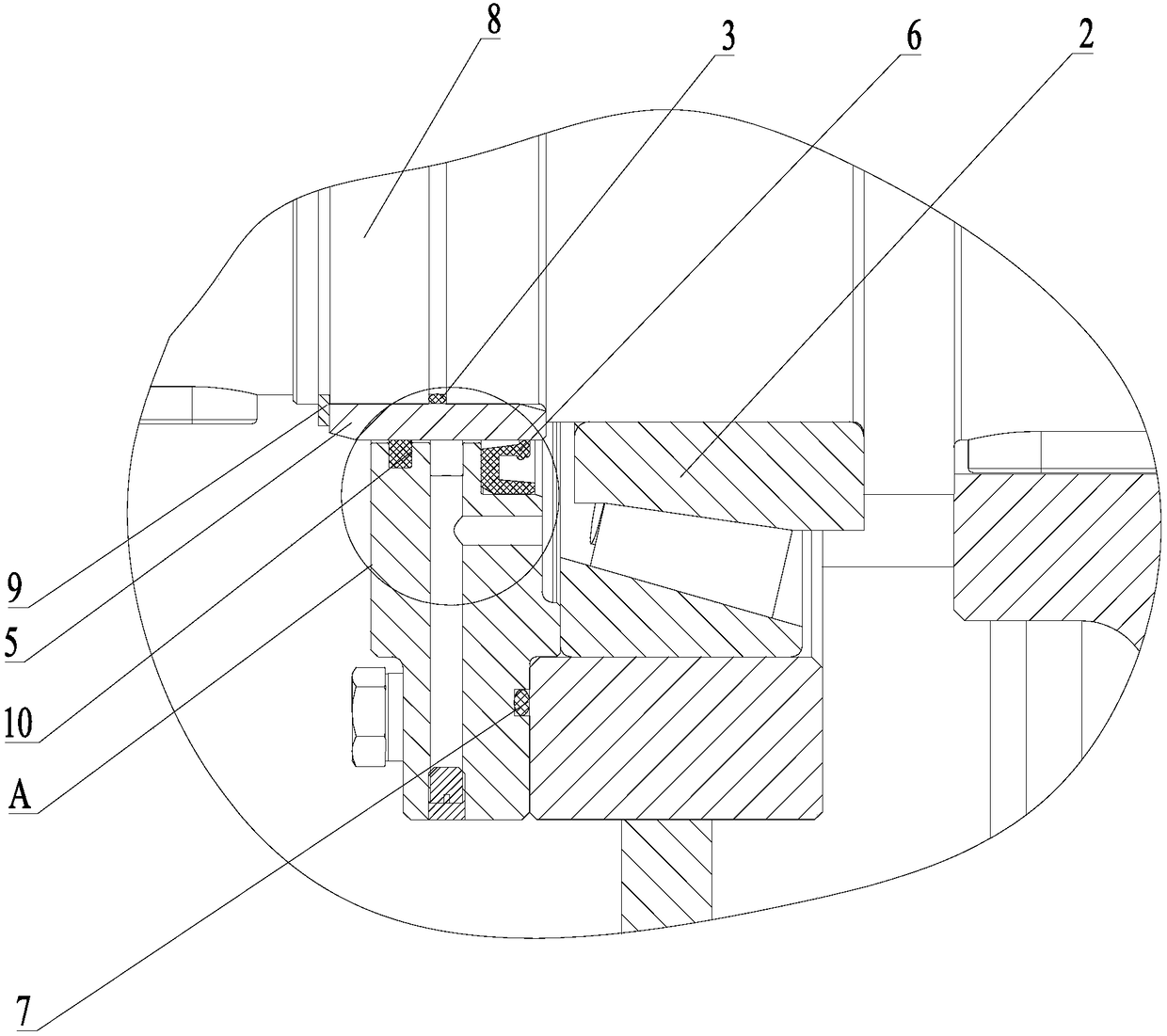

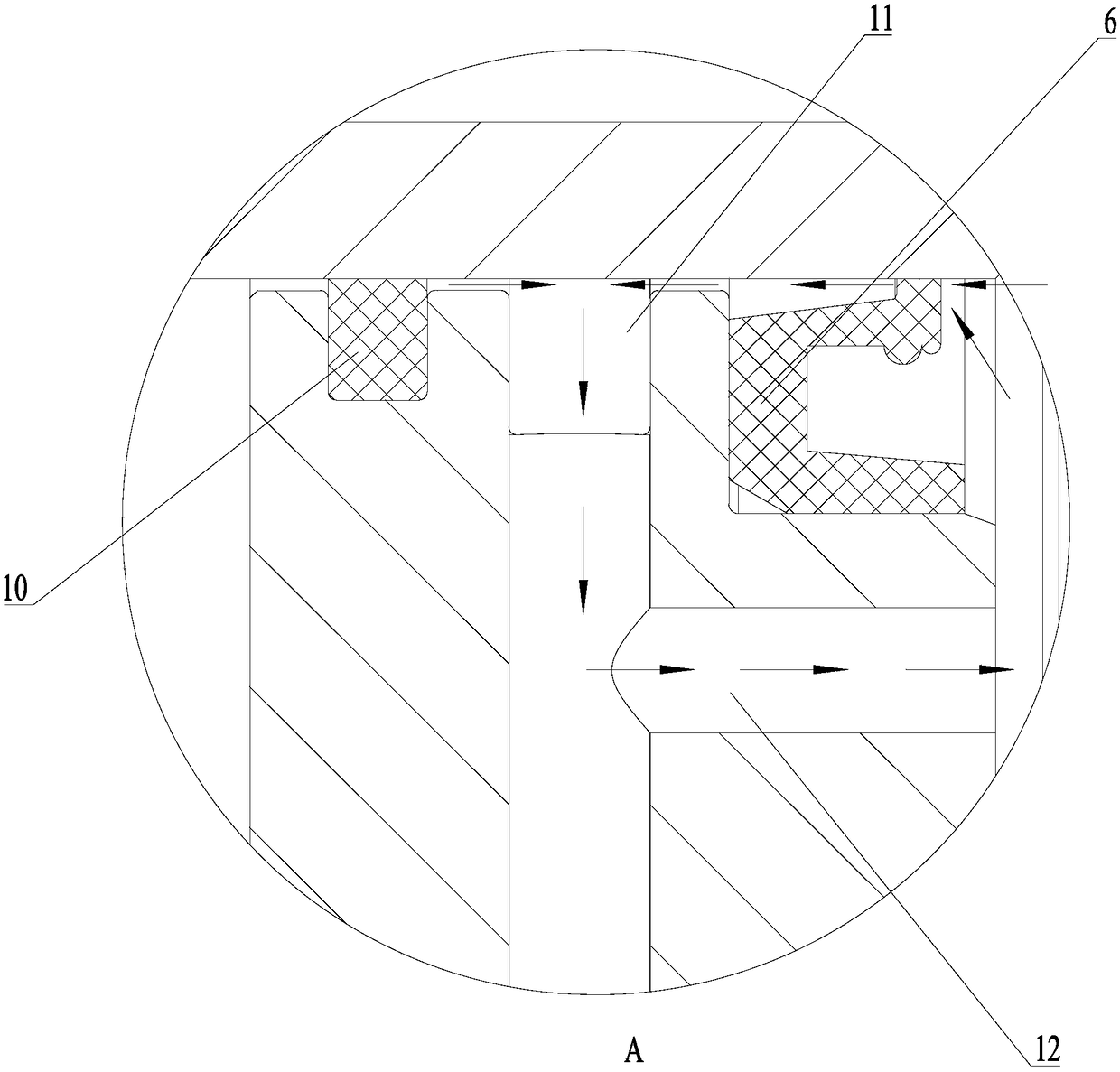

[0019] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

[0020] A shaft end oil seal structure of a gearbox, comprising an oil seal assembly located at the shaft end of a rotating shaft of a gearbox, the oil seal assembly includes a dynamic oil seal assembly and a static oil seal assembly, the dynamic oil seal assembly and the static oil seal assembly are interspersed and arranged, the A wear-resistant ring is sleeved on the rotating shaft. The dynamic oil seal assembly is installed on the gearbox cover and is located outside the wear-resistant ring. The dynamic oil seal assembly includes a first dynamic oil seal and a second dynamic oil seal. The first dynamic oil seal is arranged away from the shaft end of the rotating shaft and close to the bearing of the gearbox, and the second dynamic oil seal is arranged close to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com