Experimental system and method for simulating explosion shock wave and single fragment composite load

An explosion shock wave and composite load technology, used in instruments, measuring devices, scientific instruments, etc., can solve the problem of inability to simulate the coupling effect of shock waves and fragments, and achieve the effect of strong repeatability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

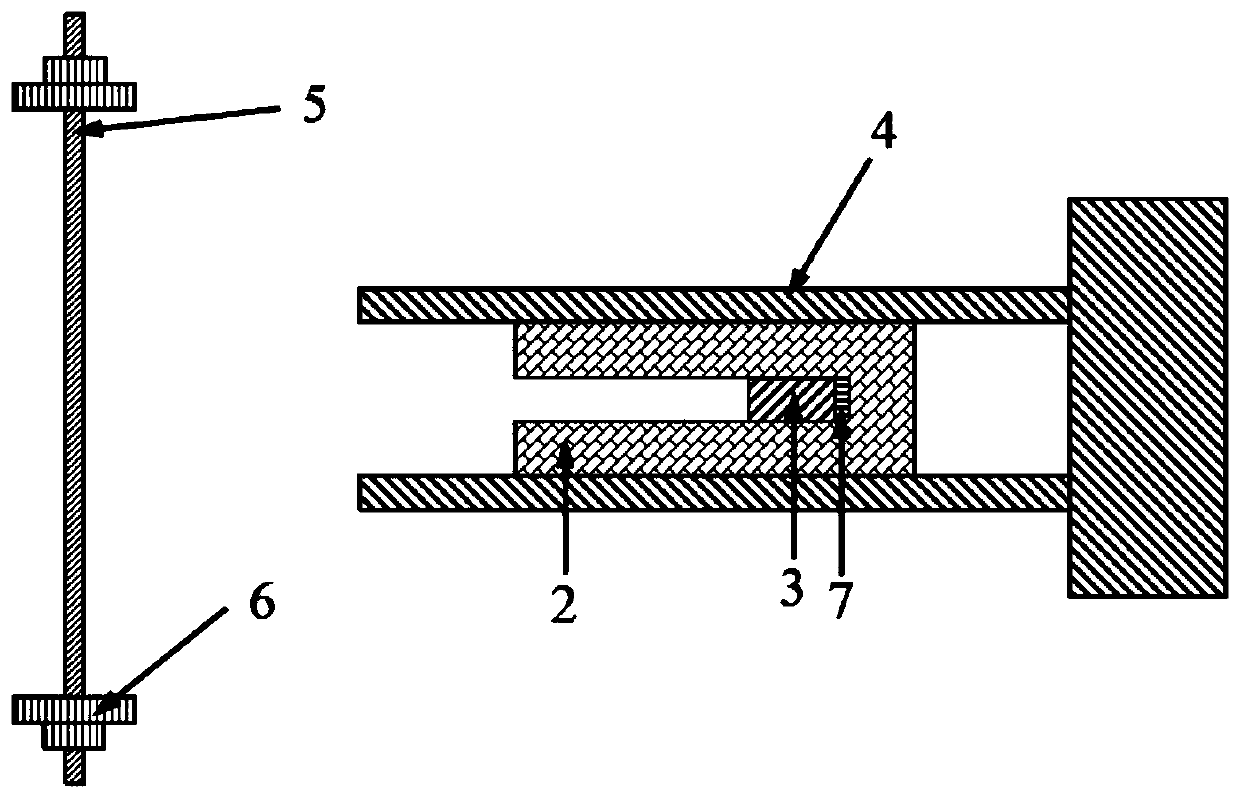

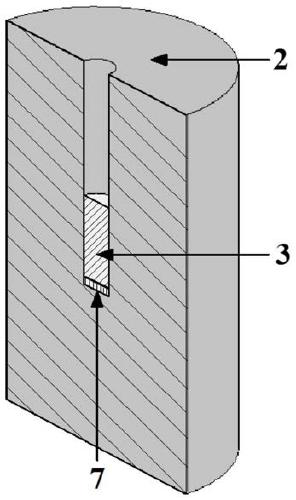

Embodiment 1

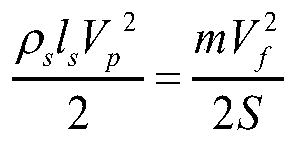

[0084] In order to simulate the compound load at 2m when a 100kg shelled bomb with 50% TNT explodes, first calculate the load parameters of the bomb at 2m: the shock wave peak value is 12MPa, the decay time is 1.4ms, and the specific kinetic energy of 8g fragments is 2.3MJ / m 2 , the time interval between shock wave and fragment reaching 2m is 0.24ms. According to the above parameters, the parameters of the composite projectile are calculated as follows: the density of the aluminum foam projectile is 270kg / m 3 , crushing platform stress 1.2MPa, length 98.0mm, opening diameter 8.4mm, depth 65.0mm, fragment simulation projectile length 20.0mm, diameter 8.0mm and composite projectile launch speed 170m / s.

[0085] According to the parameters of the composite projectile obtained above, the composite projectile is prepared and launched from the first-stage light gas gun at a speed of 170m / s, so as to form the required composite load at the projectile landing site.

Embodiment 2

[0087] In order to simulate the composite load at 0.5m when an 8kg landmine with 50% TNT explodes, first calculate the load parameters at 0.5m after the mine explodes: the peak value of the shock wave is 66MPa, the decay time is 0.35ms, and the specific kinetic energy of the 2g fragment is 3.2MJ / m 2 , the time interval between shock wave and fragment reaching 0.5m is 0.05ms. According to the above parameters, the parameters of the composite projectile are calculated as follows: the density of the aluminum foam projectile is 324kg / m 3 , The crushing platform stress is 1.7MPa, the length is 70mm, the diameter of the opening is 8.4mm, and the depth is 25mm, the length of the fragment simulation projectile is 5mm, the diameter is 8mm, and the launch speed of the composite projectile is 400m / s.

[0088] Prepare the compound projectile according to the parameters of the compound projectile obtained above and launch it from the first-stage light gas cannon at a speed of 400m / s, so a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com