Culminated turboshaft engine, turboshaft engine culvert control system and control method

A turboshaft engine and control system technology, applied in the field of aero-engines, can solve the problem of low utilization rate of the bypass air flow of the particle separator, achieve the effects of improving the outlet flow field distribution, getting rid of enemy aircraft tracking, and improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

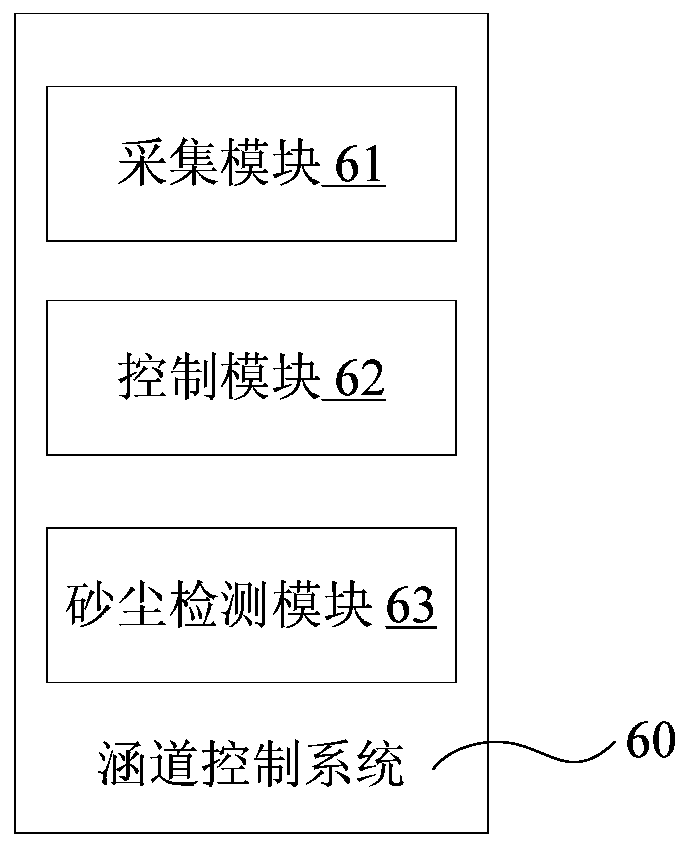

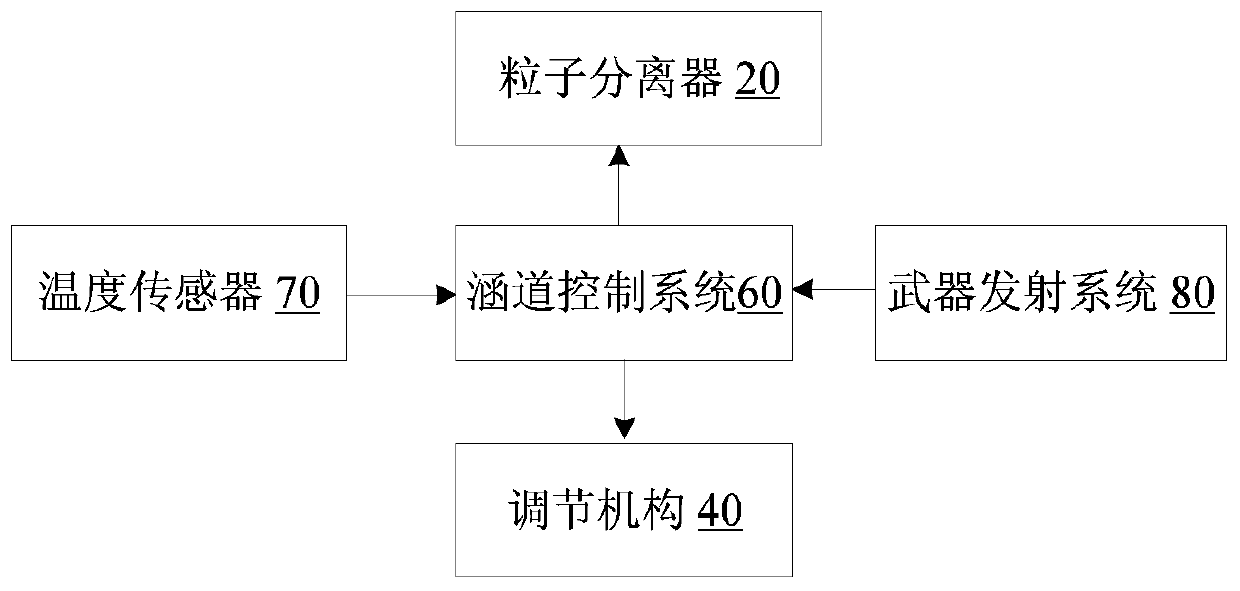

[0069] The second embodiment of the turboshaft engine bypass control method of the present invention: the control method includes the following steps:

[0070] Collect the temperature of the power cabin, the weapon launch signal and the operating environment of the helicopter;

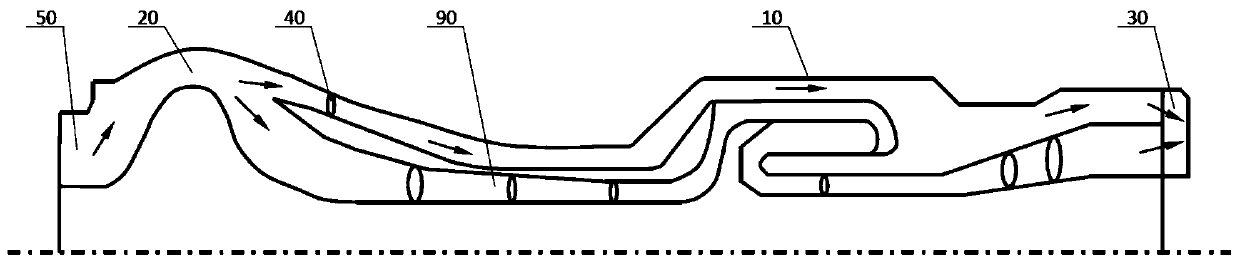

[0071] When the weapon launch signal is collected, the bypass air flow of the particle separator 20 is opened, the adjustment mechanism 40 is controlled, the flow channel area of the entrance of the outer duct 10 is increased, and the air flow entering the outer duct 10 is increased.

[0072] In this embodiment, according to the received weapon launch signal, the synchronous control adjustment mechanism 40 increases the air flow rate entering the outer duct 10 to minimize the infrared radiation of the engine tail nozzle 30 .

no. 3 example

[0073] The third embodiment of the turboshaft engine bypass control method of the present invention: the control method includes the following steps:

[0074] Collect the temperature of the power cabin, the weapon launch signal and the operating environment of the helicopter;

[0075] Determine whether there are sand and dust particles in the operating environment of the helicopter. When there are sand and dust particles in the collection operation environment, open the bypass air flow of the particle separator 20; when the collection operation environment has no sand and dust particles, close the bypass of the particle separator 20 airflow.

no. 4 example

[0076] The fourth embodiment of the turboshaft engine bypass control method of the present invention: the control method includes the following steps:

[0077] Collect the temperature of the power cabin, the weapon launch signal and the operating environment of the helicopter;

[0078] When the helicopter is running in an environment with sand and dust, open the bypass air flow of the particle separator 20 to judge whether the temperature of the power cabin is greater than the preset value. The flow channel area increases the air flow entering the outer duct 10;

[0079] When the helicopter is running in an environment without sand and dust, close the bypass air flow of the particle separator 20; judge whether the temperature of the power cabin reaches a preset value, and when greater than the preset value, open the bypass air flow of the particle separator 20 to control The adjustment mechanism 40 expands the flow channel area of the outer duct 10 to increase the air flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com