Industrial internet system of intelligent rice processing factory

A processing intelligence, Internet technology, applied in the direction of comprehensive factory control, comprehensive factory control, general control system, etc., can solve the problem of not being able to realize intelligent factory, and achieve the effect of simple structure, wide application range and small delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

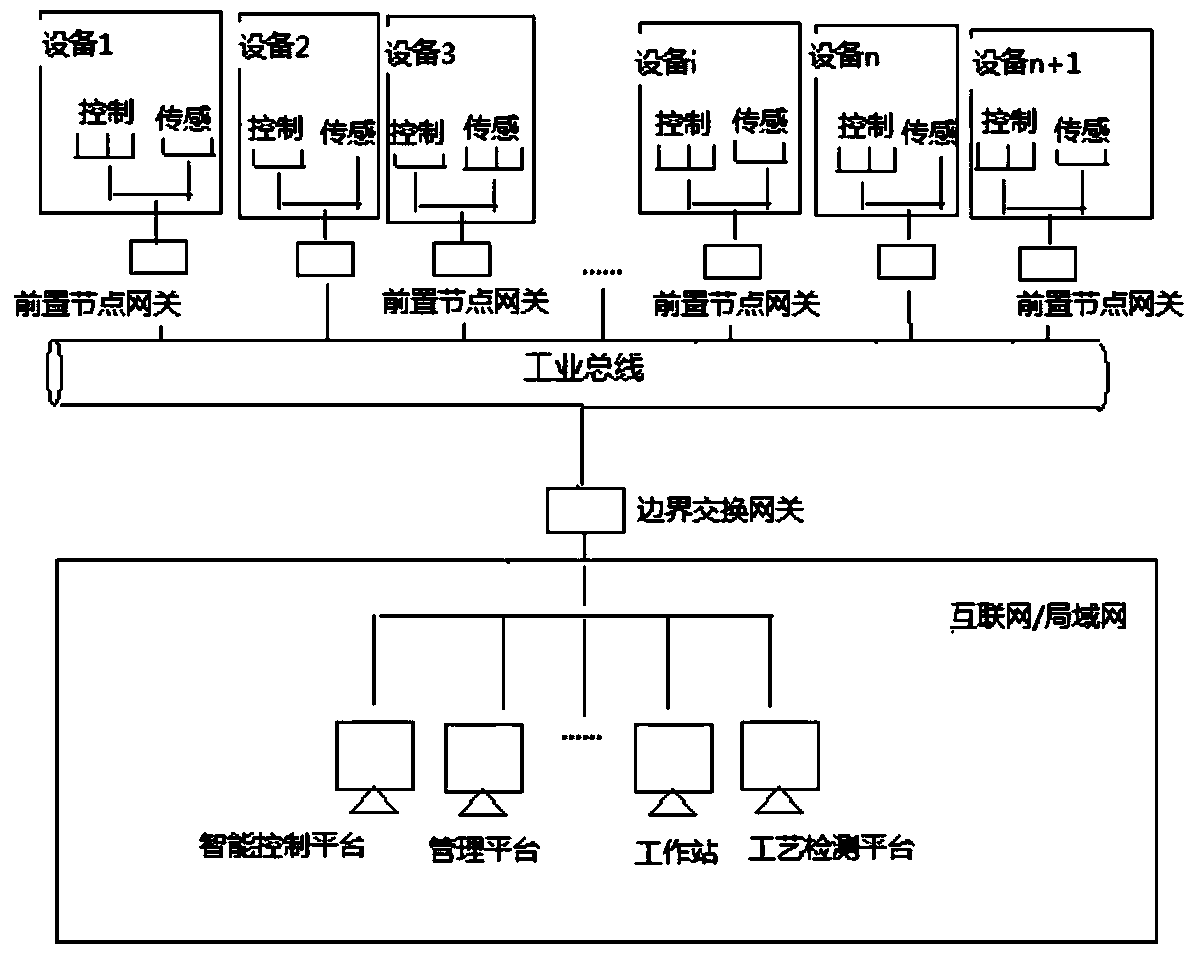

[0031] Such as figure 1 Shown, the industrial Internet network system of the rice processing intelligent factory of the present invention comprises:

[0032] Industrial bus, as the industrial main network bus of rice processing intelligent factory;

[0033] The border switching gateway is responsible for the intercommunication between the industrial bus and the Internet and / or LAN, and is mainly responsible for the forwarding of information. For the border gateway, all information is transparent;

[0034] The front-end node gateway, the front-end node gateway communicates with the CAN bus upward, and connects downward with the sensor network and control network (equipment control execution system) of the production equipment (node).

[0035] In a specific application example, the present invention can continuously increase the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com