Device and method for advanced treatment of waste water collected by high-speed rail

A technology for advanced treatment and wastewater, applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. Enhance the oxidation capacity and ozone mass transfer capacity, reduce the risk of biological toxicity, and reduce the effect of system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

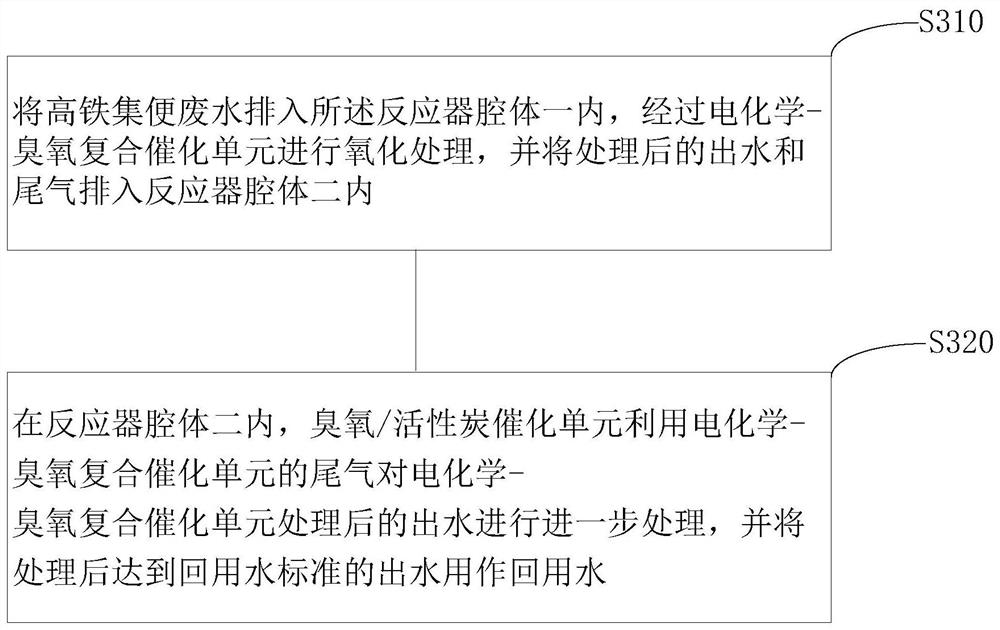

[0054] The embodiment of the present invention provides an advanced treatment device and method for high-speed rail waste water collection. The high-speed rail waste water is sequentially processed through a composite catalytic unit and a secondary catalytic unit, and finally realizes conventional indicators in the waste water and new types of pharmaceutical pollution. Efficient, fast and safe treatment of waste, so that the treated water can meet the reuse requirements.

[0055] An aspect of the embodiments of the present invention provides an advanced treatment device for waste water collected by high-speed railways.

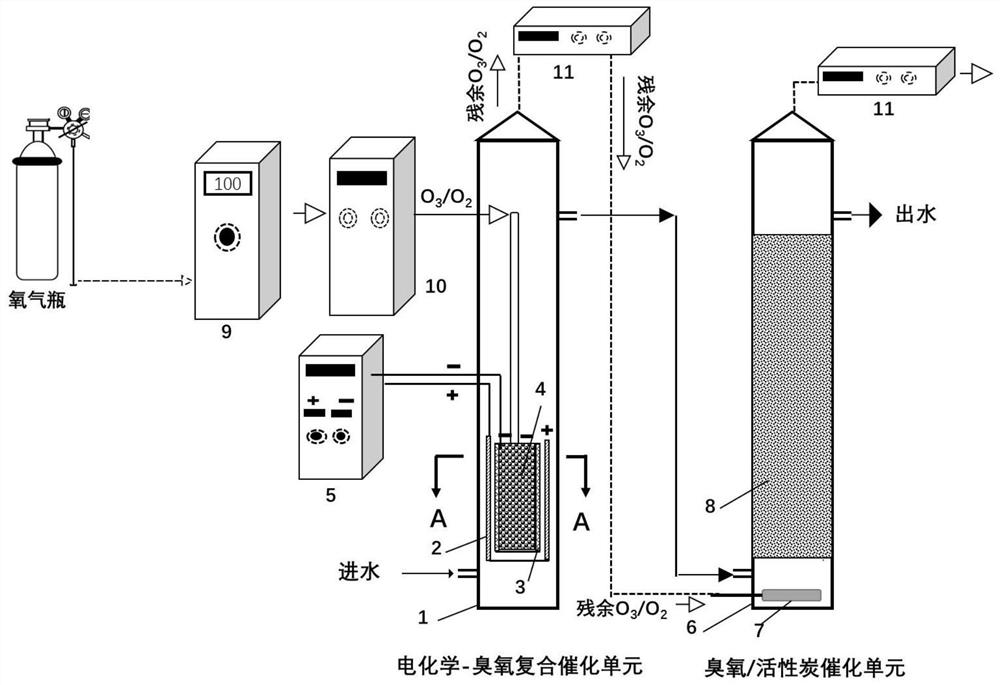

[0056] A schematic structural diagram of an advanced treatment device for high-speed rail waste water provided by an embodiment of the present invention is as follows figure 1 As shown, the device includes: an electrochemical-ozone catalytic composite unit, an ozone / activated carbon catalytic unit, an ozone generating unit and an ozone detection unit, the ozon...

Embodiment 2

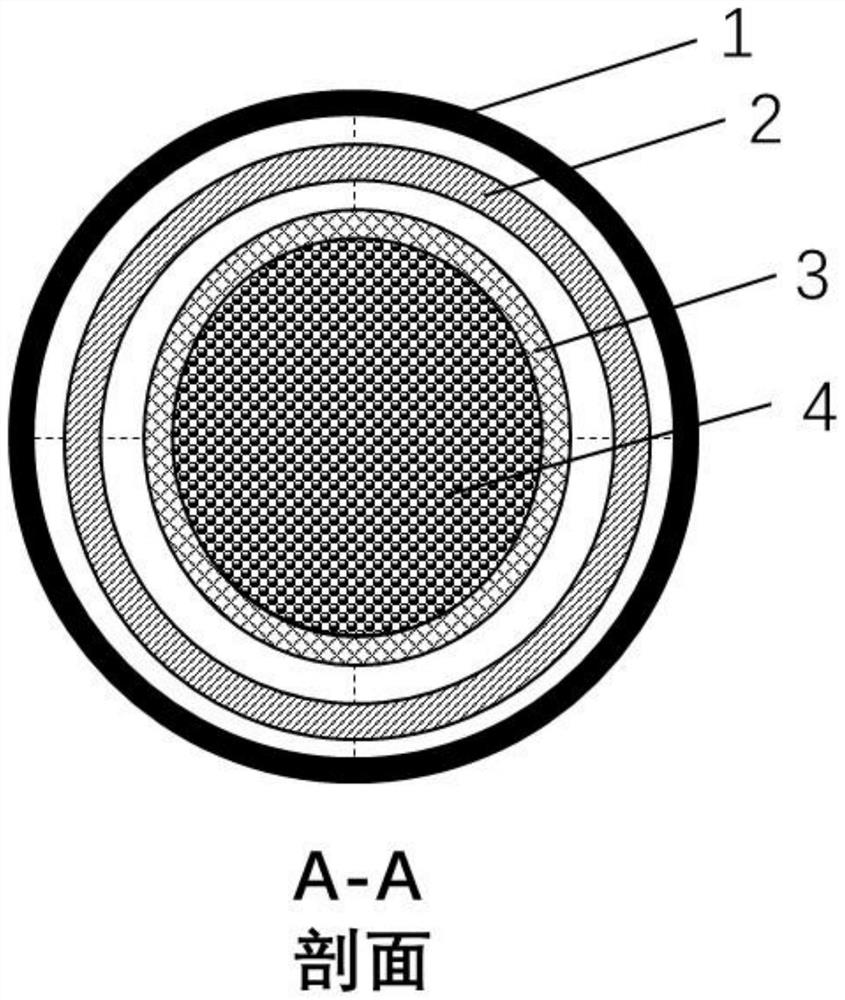

[0089] This embodiment provides a high-speed rail waste water advanced treatment device, the specific implementation structure is as follows figure 1 and figure 2 As shown, it may specifically include the following components: a reactor cavity 1, a barrel-shaped titanium-based coated anode 2, a stainless steel aeration cathode 3, a catalyst 4 filled in the aeration cathode, a pulsed DC power supply 5, a reactor cavity Body two 6, aerator 7, granular activated carbon 8, plate type ozone generator 9, micro-nano bubble generating device 10 and ozone gas concentration detector 11.

[0090] These components constitute 4 modules: electrochemical-ozone catalytic composite unit, ozone / activated carbon catalytic unit, ozone generation unit and ozone detection unit.

[0091] The electrochemical-ozone composite catalytic unit includes: a reactor chamber 1, a barrel-shaped titanium-based coated anode 2, a stainless steel aeration cathode 3, a catalyst 4 filled in the aeration cathode, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com