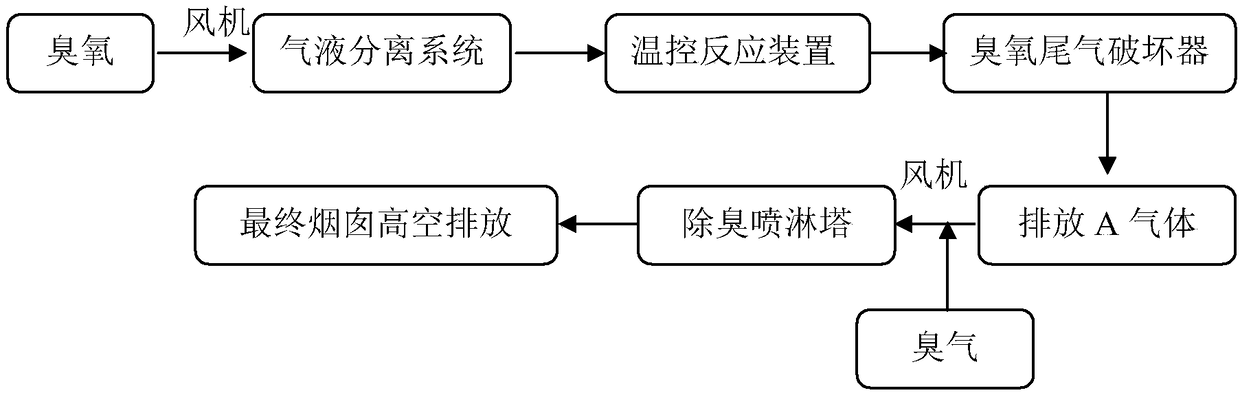

Method for improving ozone tail gas destruction efficiency in wastewater treatment

A technology for ozone tail gas and wastewater treatment, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

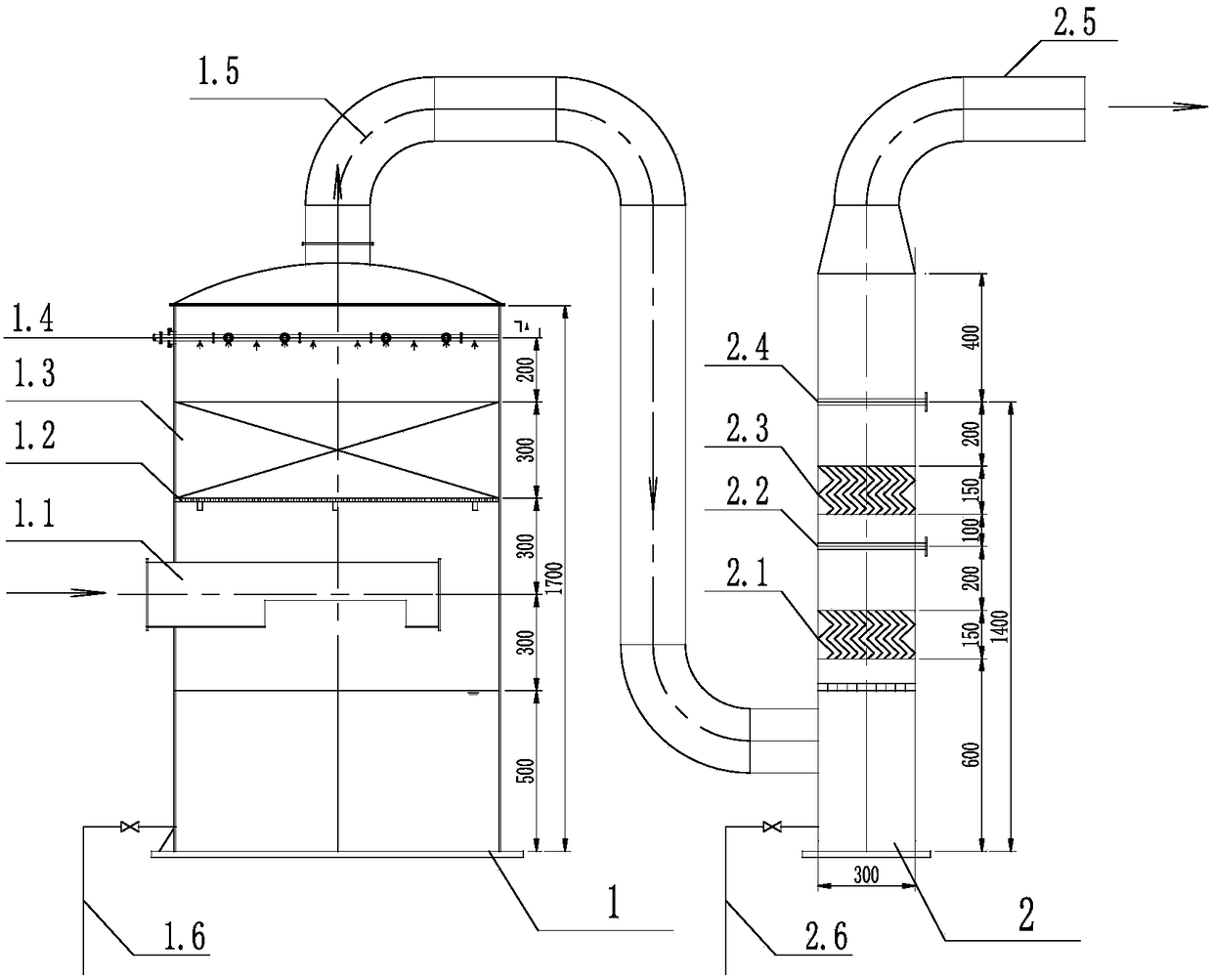

Embodiment 1

[0036] In the wastewater treatment of a certain chemical industry, 10kg / h ozone is used for wastewater treatment, and an exhaust gas discharge pipe is installed on the top of the ozone contact oxidation tank. The ozone tail gas is collected through the pipeline and enters the inlet 1.1 of the packing absorption tower 1 of the gas-liquid subsystem. Inside, the thickened FRP support grid plate 1.2 enters the packing layer 1.3, and after the rising gas fully contacts with the liquid sprayed from the upper spray pipe 1.4, it enters the bottom of the demister tower 2 through the gas outlet pipe 1.5, and the gas and the flushing pipe of the lower demister The liquid is sprayed out in 2.2, and after preliminary gas mist separation in the lower corrugated plate demister 2.1, the liquid is sprayed out from the flushing pipe 2.4 of the upper corrugated plate demister, and the final gas mist separation is carried out in the upper corrugated plate demister 2.3, and the clean gas passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com