Efficient treatment equipment for industrial ozone-containing waste gas

A kind of treatment equipment and high-efficiency technology, applied in the separation of dispersed particles, chemical instruments and methods, filtration of dispersed particles, etc., can solve the problems of insufficient exhaust gas treatment, low ozone removal rate, human health hazards, etc., to save energy consumption, The effect of ensuring filter quality and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

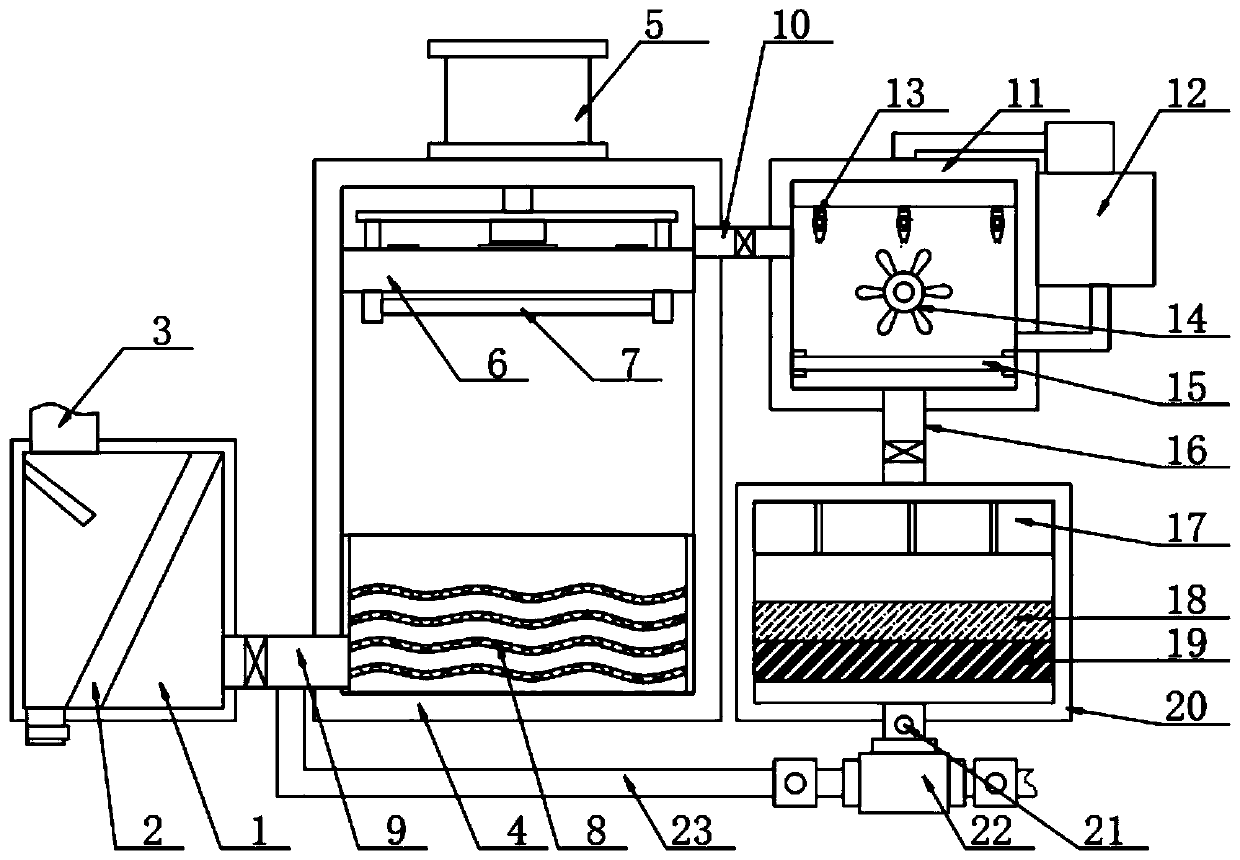

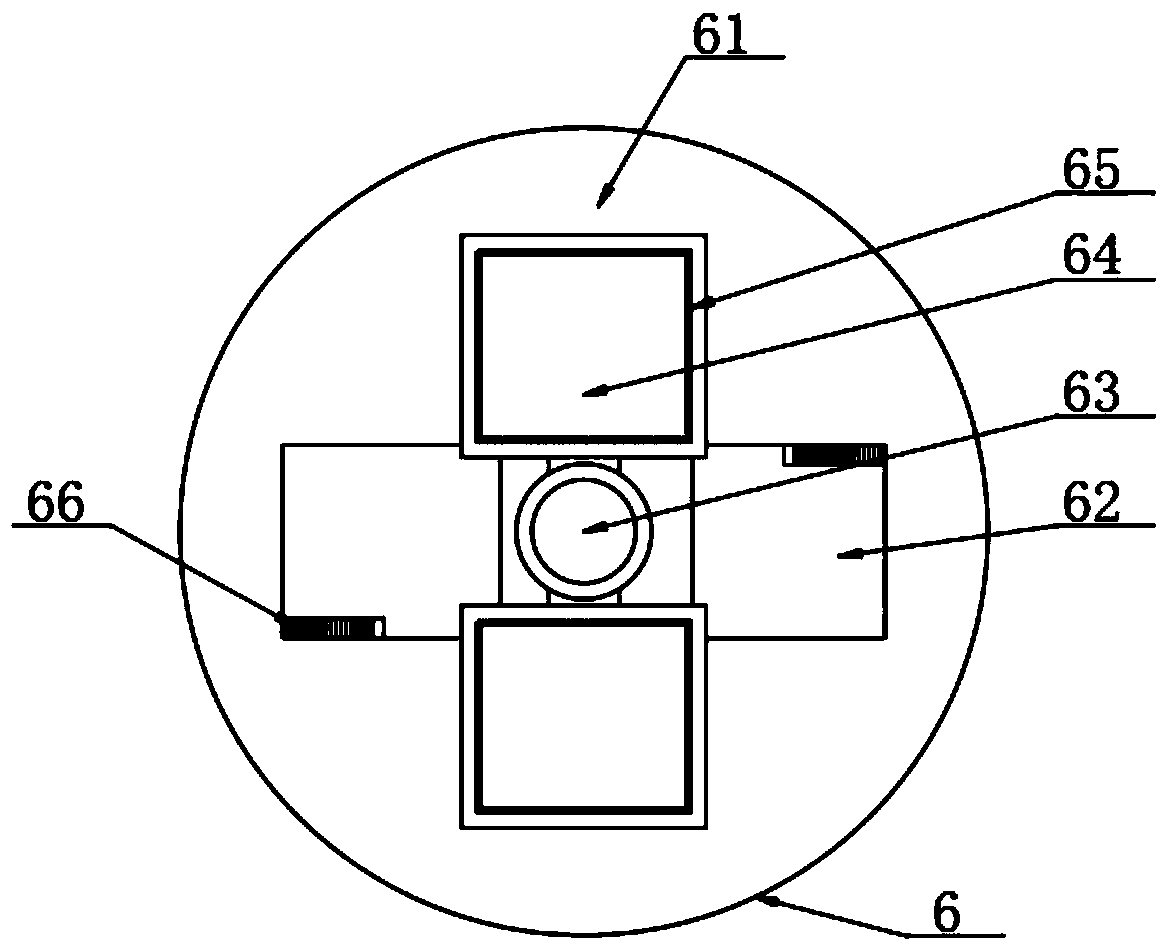

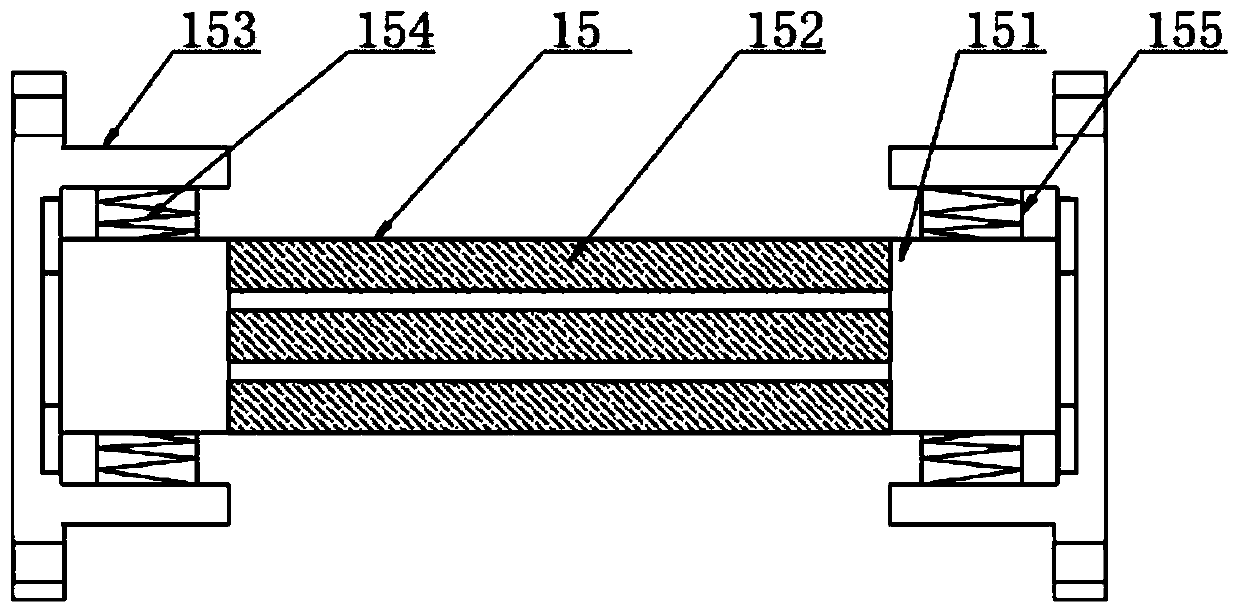

[0044]Embodiment: connect the connection inlet pipe 3 with the equipment for external input of exhaust gas, the exhaust gas enters the preliminary purification shell 1 through the connection inlet pipe 3, filters the solid particles in the exhaust gas through the filter plate 2, and then enters the decomposition through the connecting pipe 9 Inside the casing 4 and below the heating piston 6, start the high-temperature heating tube 7 and the cylinder 5, the cylinder 5 drives the heating piston 6 downward, presses the exhaust gas downward, the high-temperature heating tube 7 heats the exhaust gas at high temperature, and the heat storage plate 8 Heat absorption, exhaust gas heating, removal of a certain concentration of ozone in the exhaust gas, after heating for a certain period of time, start the micro motor 63 to rotate clockwise, so that the sealing baffle 64 does not block the port 62, and the heated gas passes through the port 62 It flows upwards, then enters the spray hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com