Microbial control system of cleaning operation area and using method thereof

A technology for controlling systems and operating areas, applied in air-conditioning systems, applications, household heating, etc., can solve problems such as poor disinfection effects, and achieve the effect of maintaining cleanliness, good disinfection effects, and guaranteed disinfection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

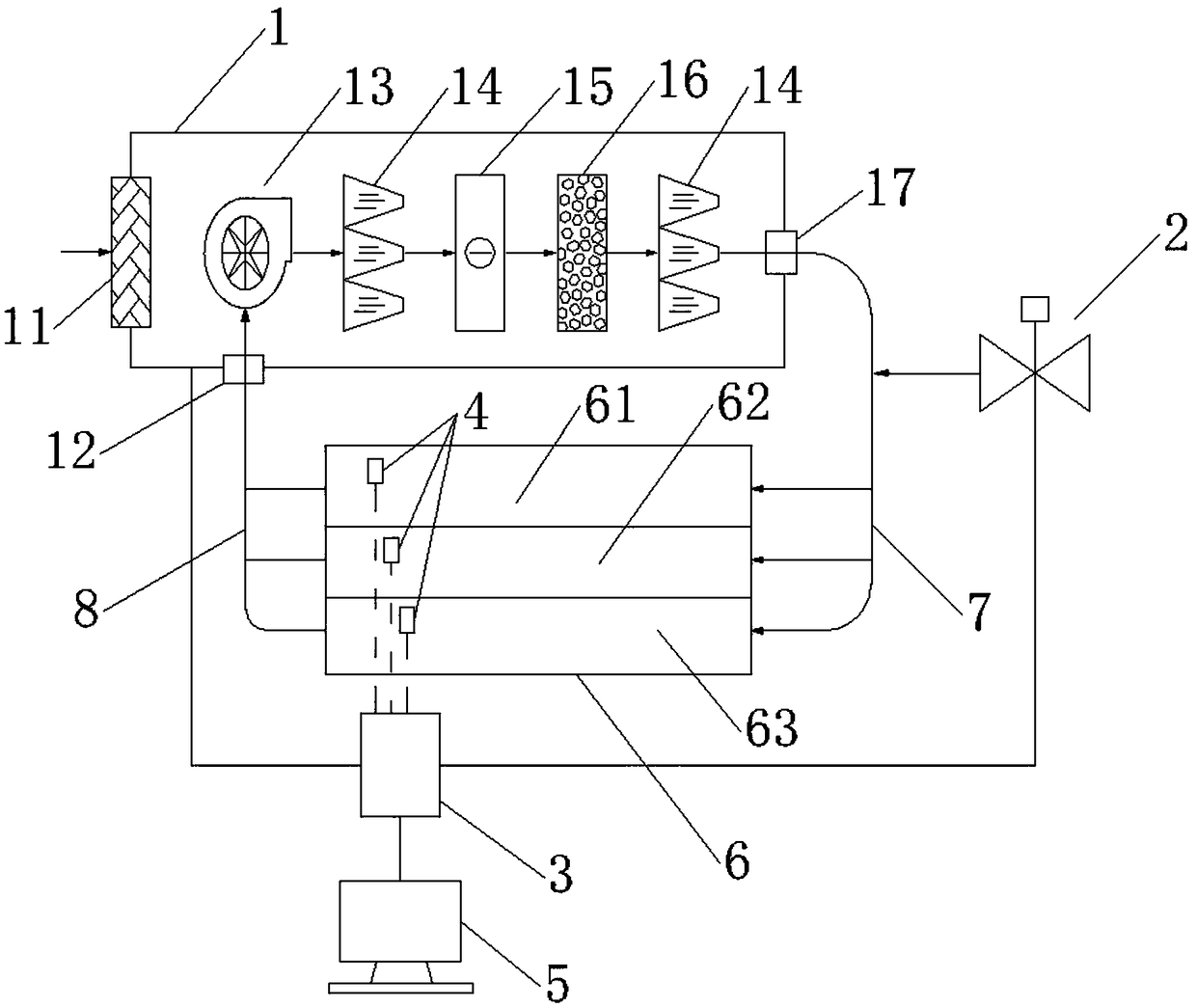

Method used

Image

Examples

Embodiment 1

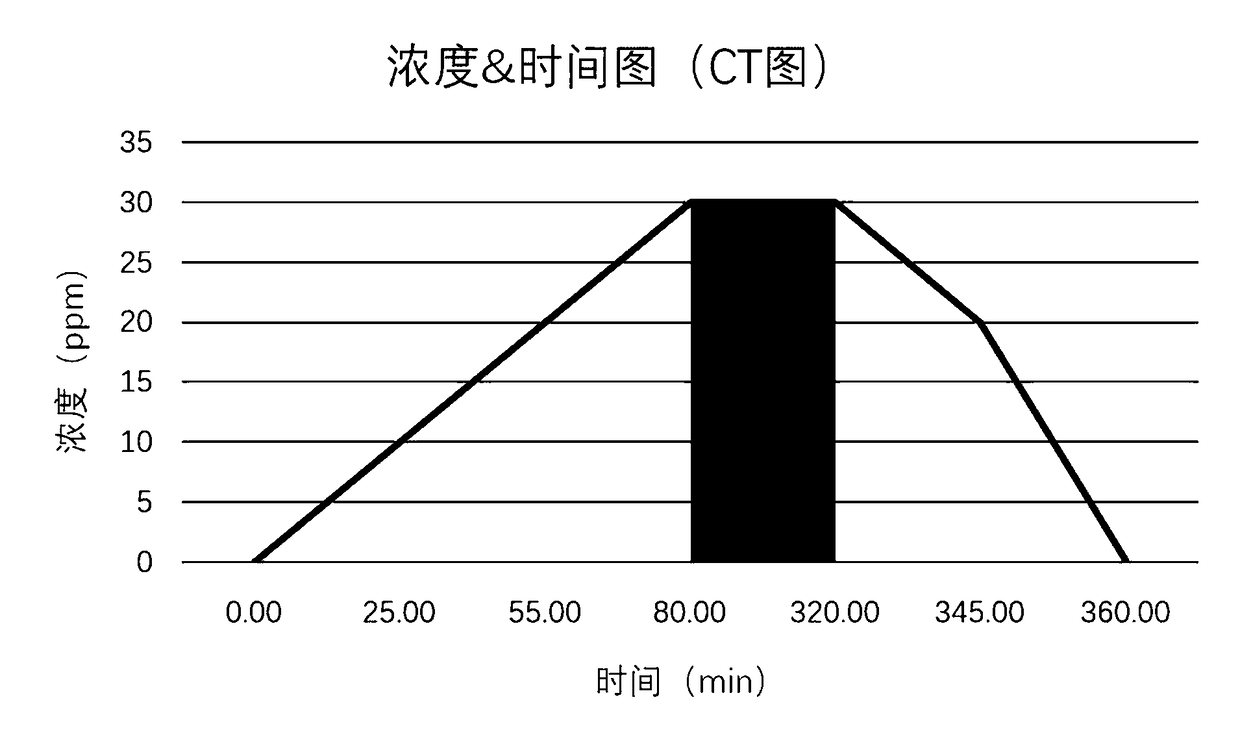

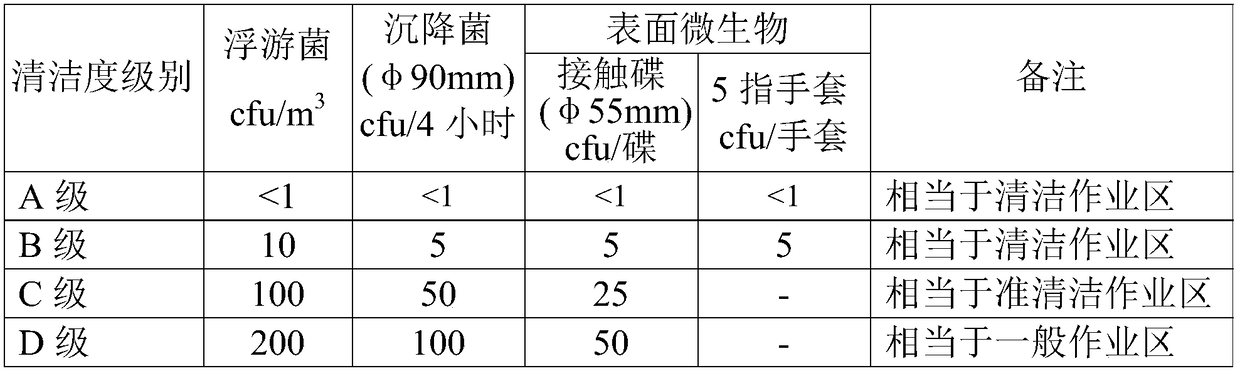

[0049] 1) After cleaning the equipment and facilities in the clean area, close the fresh air inlet 11 of the clean air conditioner 1, stop the fresh air supply, turn on the ozone generator 2, and send ozone into the air in the clean operation area 6 through the air outlet duct 7 of the clean air conditioner 1 , when the detected value of the ozone concentration detector 4 in each operation area reaches 25ppm, start counting.

[0050] 2) The CT value of ozone disinfection reaches 12000mg / m 3 When min, the ozone generator 2 is stopped, and the fresh air inlet 11 of the clean air conditioner 1 is opened to supplement the clean air processed by the clean air conditioner 1 .

[0051] 3) Through the constant temperature and humidity function of the cleaning air conditioner, the temperature in the cleaning work area is controlled at 25°C and the relative humidity is controlled at 30%.

Embodiment 2

[0053] 1) After cleaning the equipment and facilities in the clean area, close the fresh air inlet 11 of the clean air conditioner 1, stop the fresh air supply, turn on the ozone generator 2, and send ozone into the air in the clean operation area 6 through the air outlet duct 7 of the clean air conditioner 1 , when the detected value of the ozone concentration detector 4 in each operation area reaches 20ppm, start counting.

[0054] 2) The CT value of ozone disinfection reaches 9000mg / m 3 When min, the ozone generator 2 is stopped, and the fresh air inlet 11 of the clean air conditioner 1 is opened to supplement the clean air processed by the clean air conditioner 1 .

[0055] 3) Through the constant temperature and humidity function of the cleaning air conditioner, the temperature in the cleaning work area is controlled at 24°C and the relative humidity is controlled at 15%.

Embodiment 3

[0057] 1) After cleaning the equipment and facilities in the clean area, close the fresh air inlet 11 of the clean air conditioner 1, stop the fresh air supply, turn on the ozone generator 2, and send ozone into the air in the clean operation area 6 through the air outlet duct 7 of the clean air conditioner 1 , when the detected value of the ozone concentration detector 4 in each operation area reaches 30ppm, start counting.

[0058] 2) The CT value of ozone disinfection reaches 14400mg / m 3 When min, the ozone generator 2 is stopped, and the fresh air inlet 11 of the clean air conditioner 1 is opened to supplement the clean air processed by the clean air conditioner 1 .

[0059] 3) Through the constant temperature and humidity function of the cleaning air conditioner, the temperature in the cleaning work area is controlled at 26°C and the relative humidity is controlled at 45%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com