3D printed vascular stent

A 3D printing and vascular stent technology, applied in the field of vascular stents, can solve problems such as poor bending adaptability, and achieve the effects of improving adaptability, avoiding blood coagulation, and prolonging anticoagulation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0043] Such as Figure 6 As shown, the front part of the stent, the back part of the stent and the connecting part are all porous mesh structures. Specifically, the connecting part is a porous circular straight tube made by 3D printing, and the two ends of the porous circular straight tube are respectively connected and fixed to the front section of the bracket and the back section of the bracket.

no. 2 example

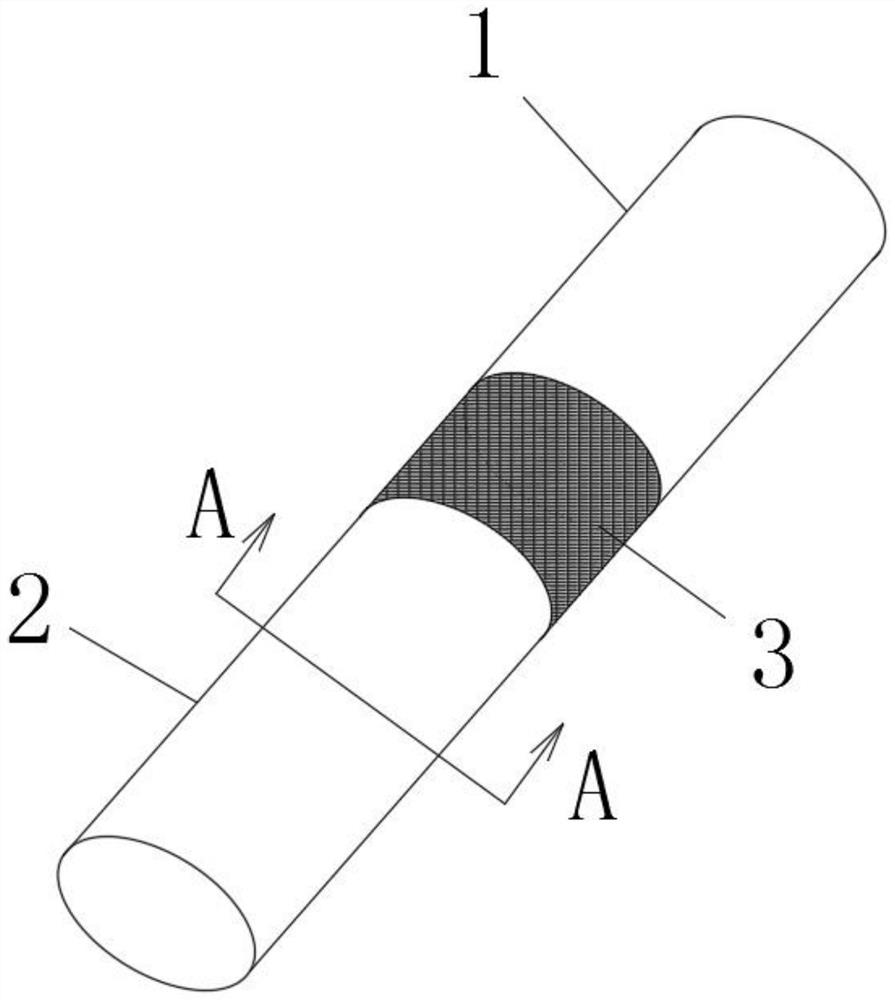

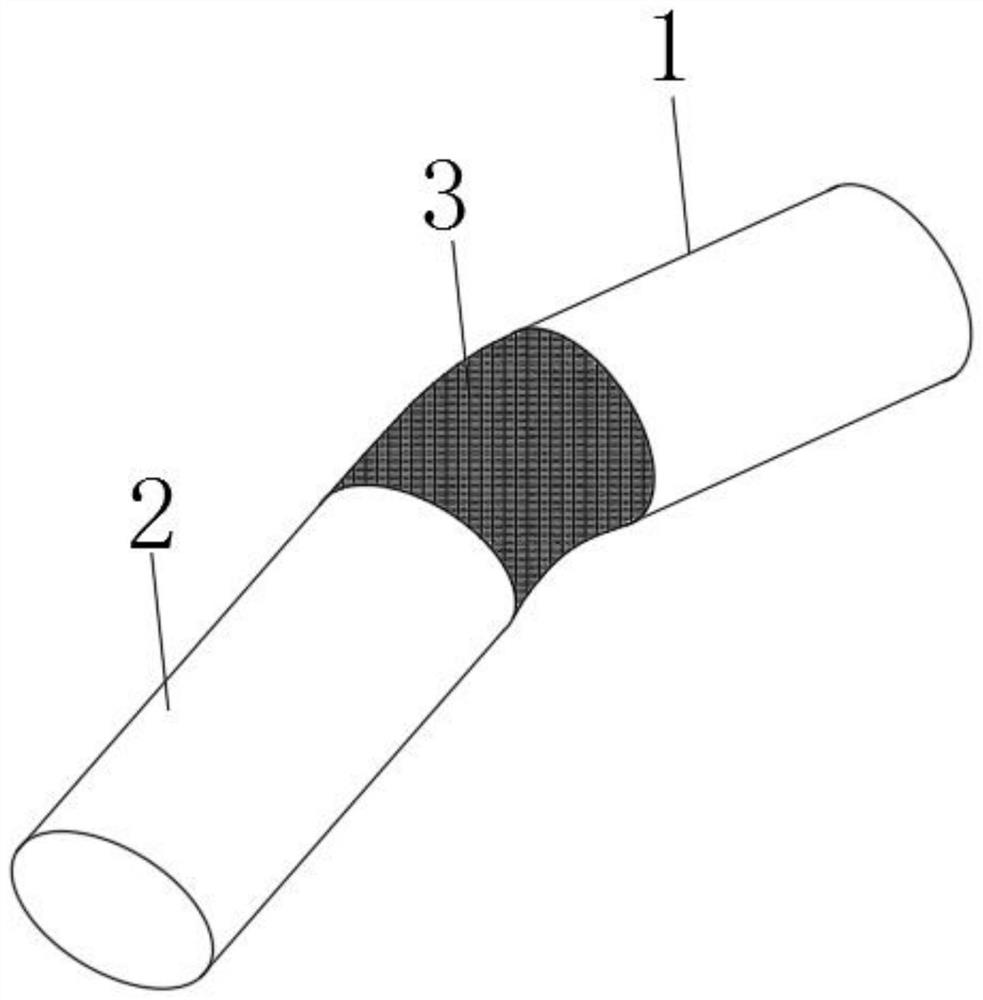

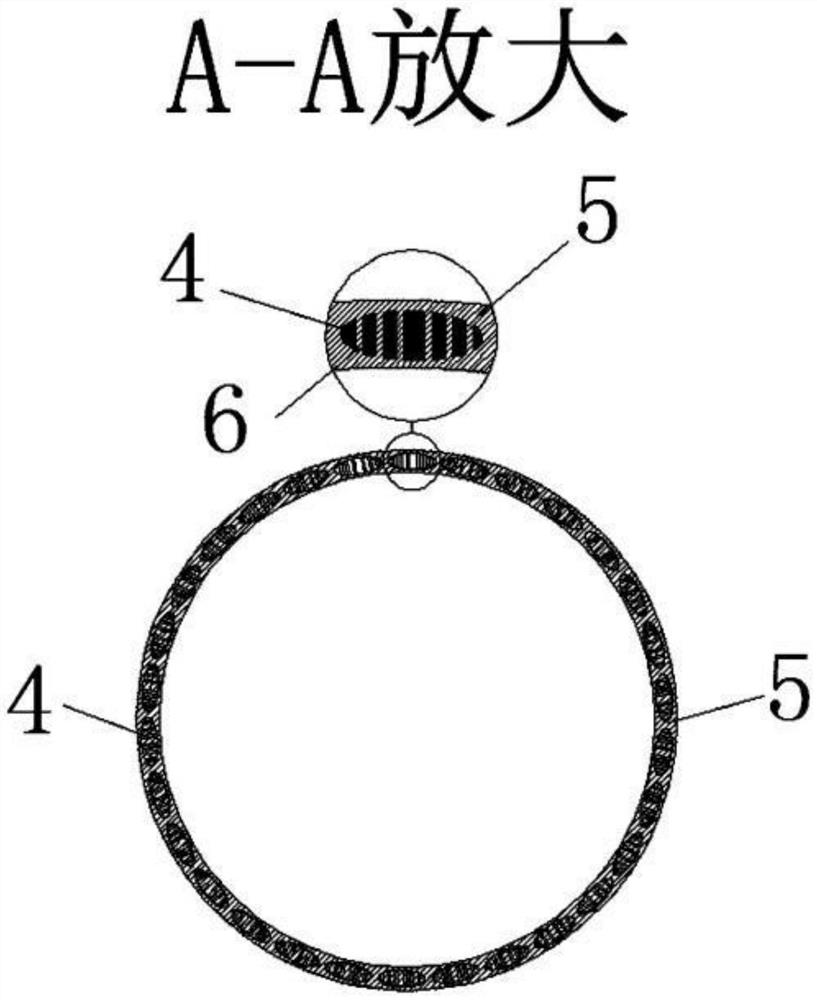

[0045] Such as Figure 7 , Figure 8 , Figure 9 As shown, the front section of the bracket and the back section of the bracket are porous mesh structures, and the connecting part is a wire harness made by 3D printing. The number of wire harnesses is not limited. Figure 7 , Figure 8 , Figure 9 The cases of one, two and four are shown respectively.

[0046] Of course, the wire harness in this embodiment can also be obtained without printing.

no. 3 example

[0048] Such as Figure 10 As shown, the front section of the bracket and the back section of the bracket in this embodiment are both cylindrical columnar structures, and the connecting part is a porous network structure. The cylindrical columnar structure is composed of a ring beam 7 and a support beam 8, and the ring beam and the support beam Multiple ring beams are arranged in parallel, and multiple support beams are arranged in parallel and evenly distributed on the circumference of any ring beam. The specific values of the width and thickness of the ring beams and support beams in this embodiment are not limited. , but at least its width / thickness is required to be greater than 1, which can make it have strong elasticity and have a better supporting effect on blood vessels, so that compared with the prior art, it can reduce the contact area with blood, reduce blood coagulation and even re- Risk of blood clots.

[0049] Through further optimization, this embodiment propo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com