Thin-specification pattern plate and production method thereof

A production method and pattern plate technology, which are applied to workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., can solve the problems of high running speed, small self-weight of strip steel, and folded head, so as to improve production efficiency and reduce coil volume. The effect of taking temperature and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) The molten steel with qualified components smelted by converter or electric furnace is continuously cast by a pair of copper casting rollers rotating in reverse to form a continuous casting strip with a thickness of 1.8mm and a continuous casting speed of 50m / min;

[0038] (2) The cast strip is rolled into a thin-gauge hot-rolled strip through two passes of hot rolling. The thickness of the hot-rolled strip is 0.7mm, the finishing temperature is 1150°C, and the rolling speed is 120m / min;

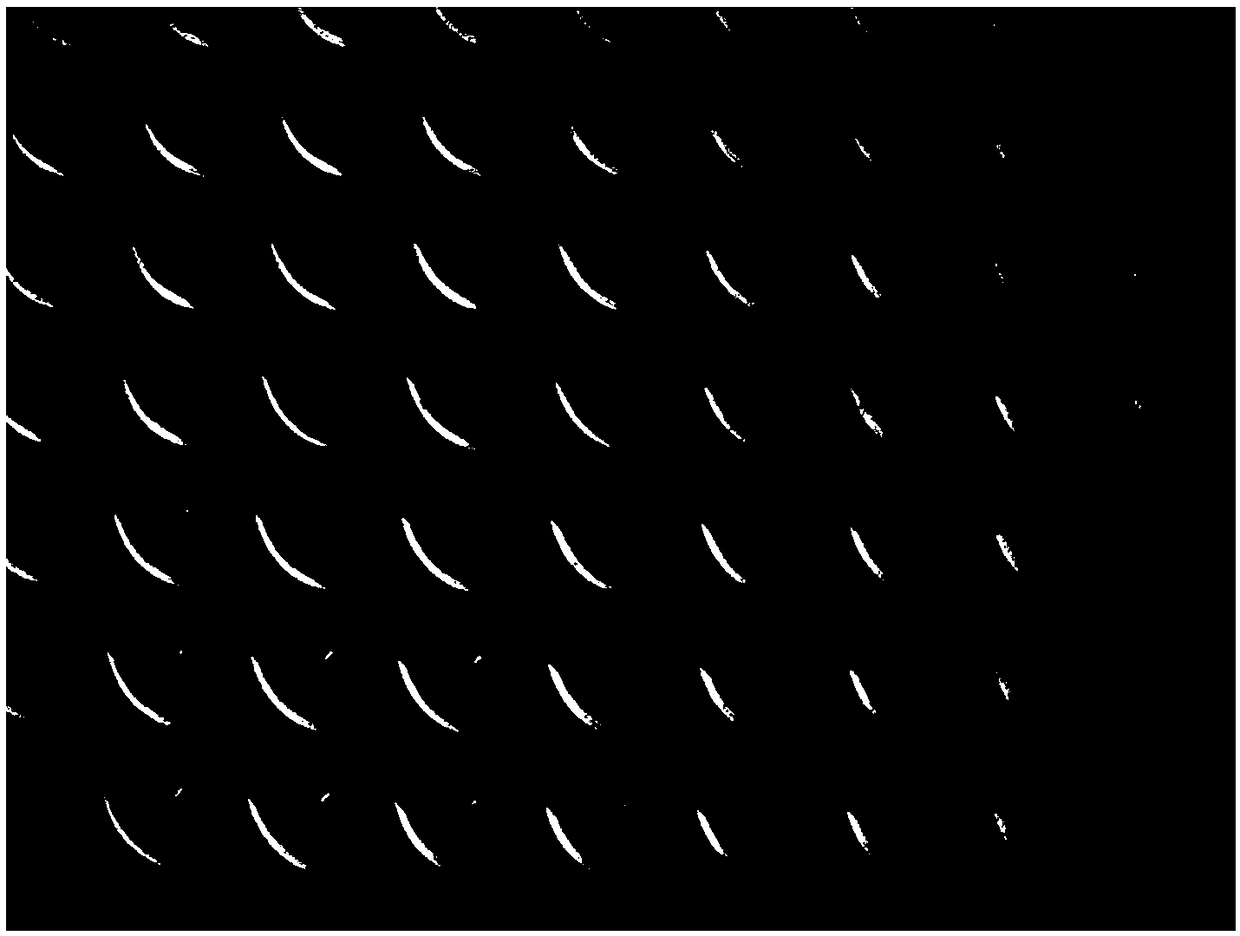

[0039] (3) A pattern rolling mill is arranged behind the hot rolling mill of the second stand, and the upper surface of the hot-rolled strip is rolled into a lentil pattern shape.

[0040] (4) Cool the checkered plate after rolling, the cooling method is air mist cooling, and coil it into coils, and the coiling temperature is 250°C.

[0041] Check the surface of the checkered plate, the rolled checkered plate has beautiful pattern and good shape.

Embodiment 2

[0043] (1) The molten steel with qualified components smelted by converter or electric furnace is continuously cast by a pair of copper casting rollers rotating in reverse to form a continuous casting strip, the thickness of the casting strip is 2.2mm, and the continuous casting speed is 40m / min;

[0044] (2) The cast strip is rolled into a thin gauge hot-rolled steel strip through one pass of hot rolling. The thickness of the hot-rolled steel strip is 2.0mm, the finish rolling temperature is 1050°C, and the rolling speed is 80m / min;

[0045] (3) A pattern rolling mill is arranged behind the hot rolling mill of the first stand, and the upper surface of the hot-rolled strip is rolled into a rhombus pattern shape.

[0046] (4) Cool the checkered plate after rolling, the cooling method is air jet cooling, and coil it into coils, and the coiling temperature is 300°C.

[0047] Check the surface of the checkered plate, the rolled checkered plate has beautiful pattern and good shape....

Embodiment 3

[0049] (1) Molten steel with qualified components smelted by converter or electric furnace is formed into a continuous casting strip by a pair of counter-rotating copper casting rolls, the thickness of the casting strip is 1.4mm, and the continuous casting speed is 75m / min;

[0050] (2) The cast strip is rolled into a thin gauge hot-rolled steel strip through one pass of hot rolling. The thickness of the hot-rolled steel strip is 1.1mm, the finishing temperature is 1180°C, and the rolling speed is 110m / min;

[0051] (3) A pattern rolling mill is arranged behind the hot rolling mill of the first stand, and the upper surface of the hot-rolled strip is rolled into a pea-shaped pattern shape.

[0052] (4) Cool the checkered plate after rolling, the cooling method is air jet cooling, and coil it into coils, and the coiling temperature is 480°C.

[0053] Check the surface of the checkered plate, the rolled checkered plate has beautiful pattern and good shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com