Intelligent and automatic operation device applicable to continuous casting table

A continuous casting and intelligent technology, which is applied to casting equipment, casting molten material containers, manufacturing tools, etc., can solve the problems of high labor intensity, health damage of operators, and low work efficiency, so as to reduce on-site operators and reduce on-site The effect on the probability of an accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

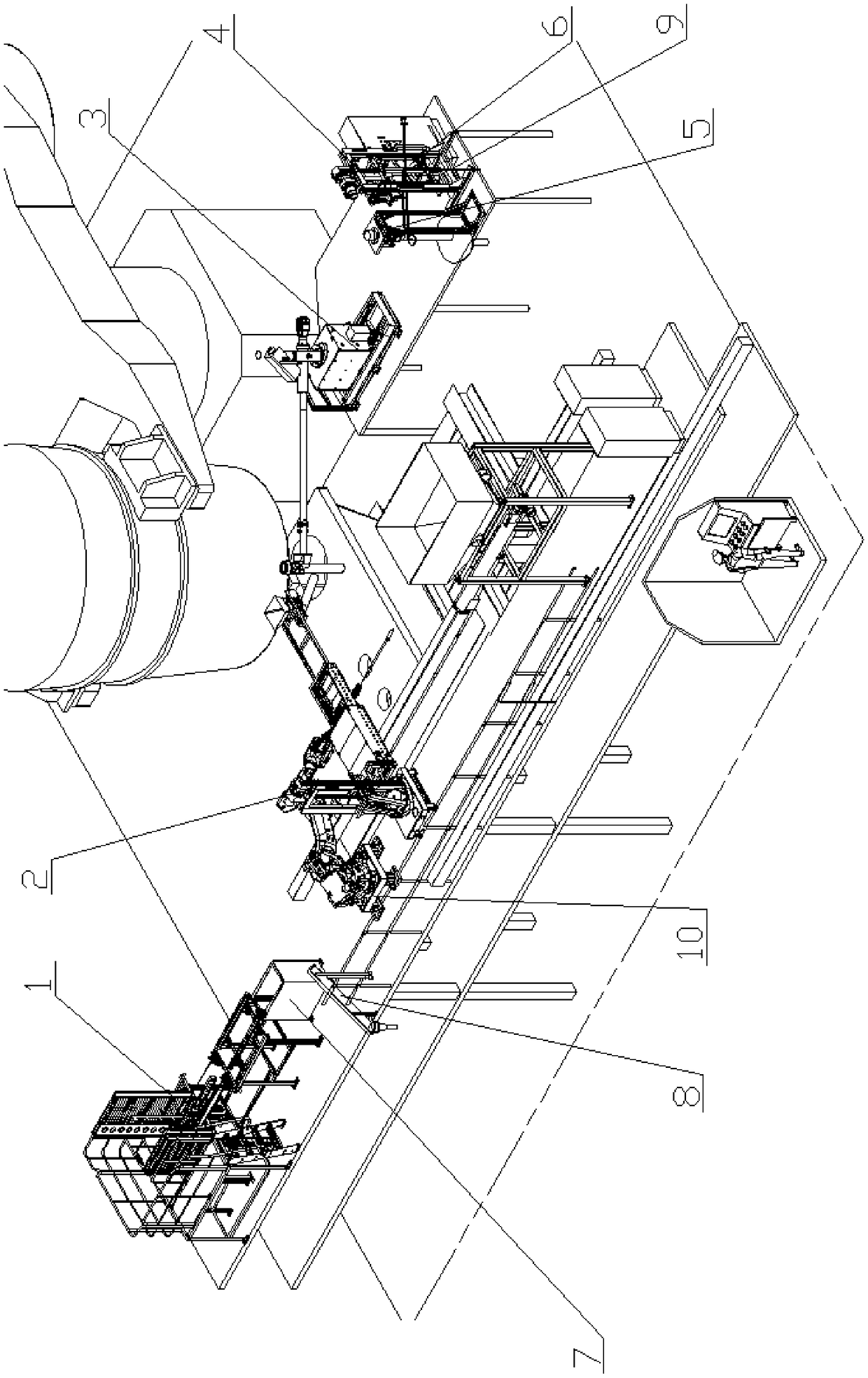

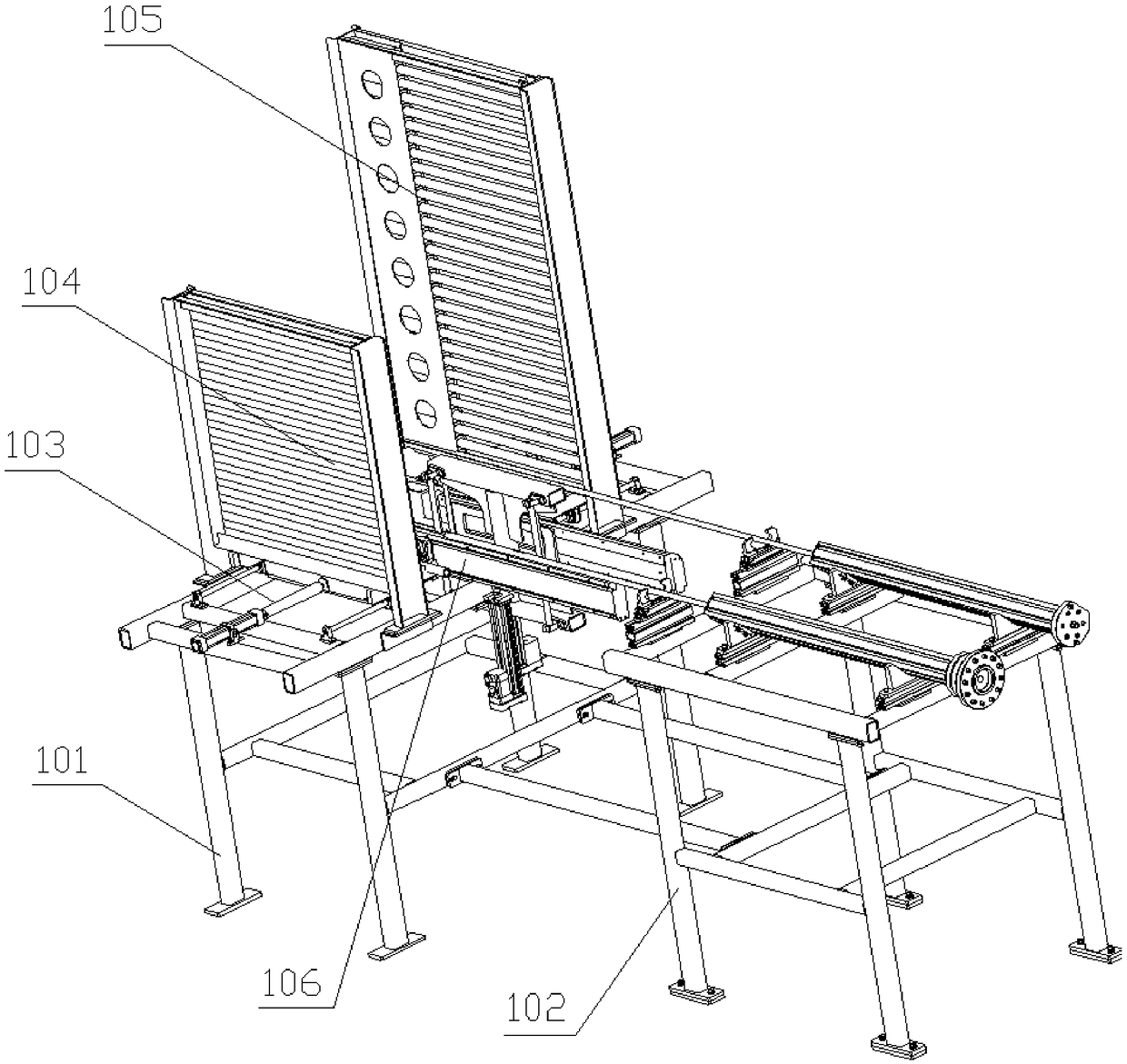

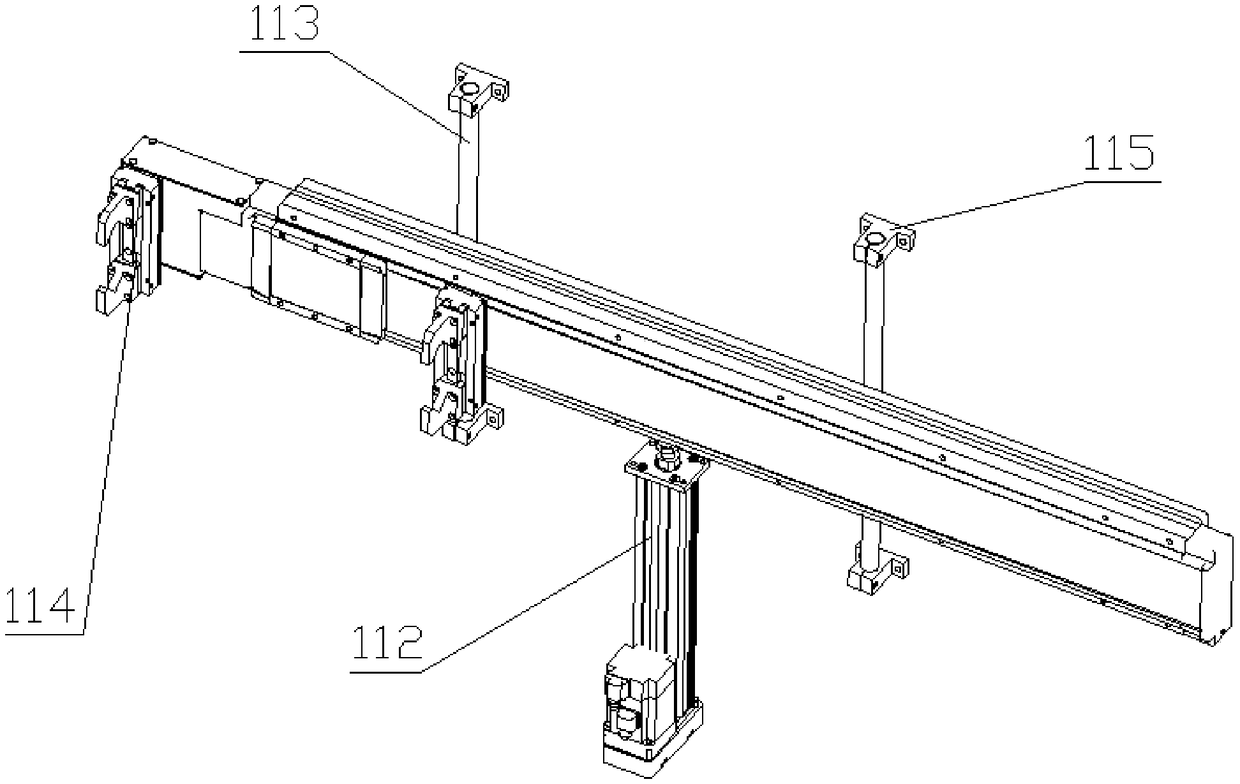

[0047] Such as Figure 1 to Figure 17 As shown in the present invention, a device suitable for intelligent automatic operation on the continuous casting platform includes a temperature measurement and sampling storage device 1, a covering agent delivery device 2, a shroud robot 3, a shroud access device 4, and a gasket storage device 5. Long nozzle recovery box 6, temperature detector recovery box 7, sampler recovery box 8 and robot 10;

[0048] There are multiple stations on the continuous casting table, and each station is equipped with a temperature measurement and sampling memory 1, a temperature detector recovery box 7, a sampler recovery box 8, a covering agent delivery device 2, a long nozzle robot 3, and a long nozzle Access device 4, gasket storage device 5, shroud recovery box 6 and robot 10; among them, the temperature measurement a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com