Omnibearing multi-axis polishing machine

A kind of polishing machine, all-round technology, applied in the direction of grinding/polishing equipment, grinding frame, grinding machine tool parts, etc., it can solve the problem of polishing quality that is difficult to achieve accurate orientation, low degree of automation, polishing workpiece quality, and efficiency , high cost and other issues, to achieve the effect of high efficiency and fully automated polishing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

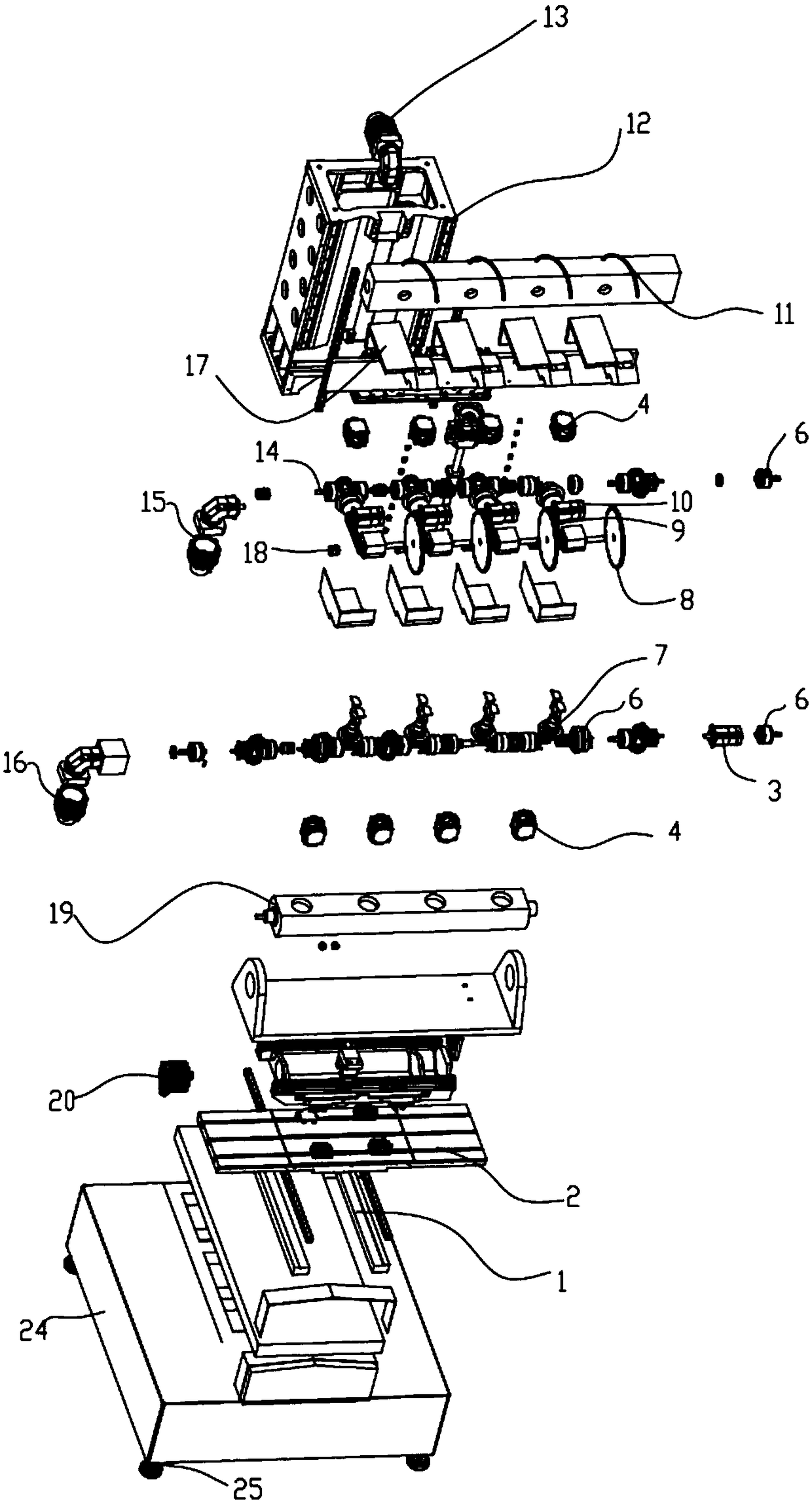

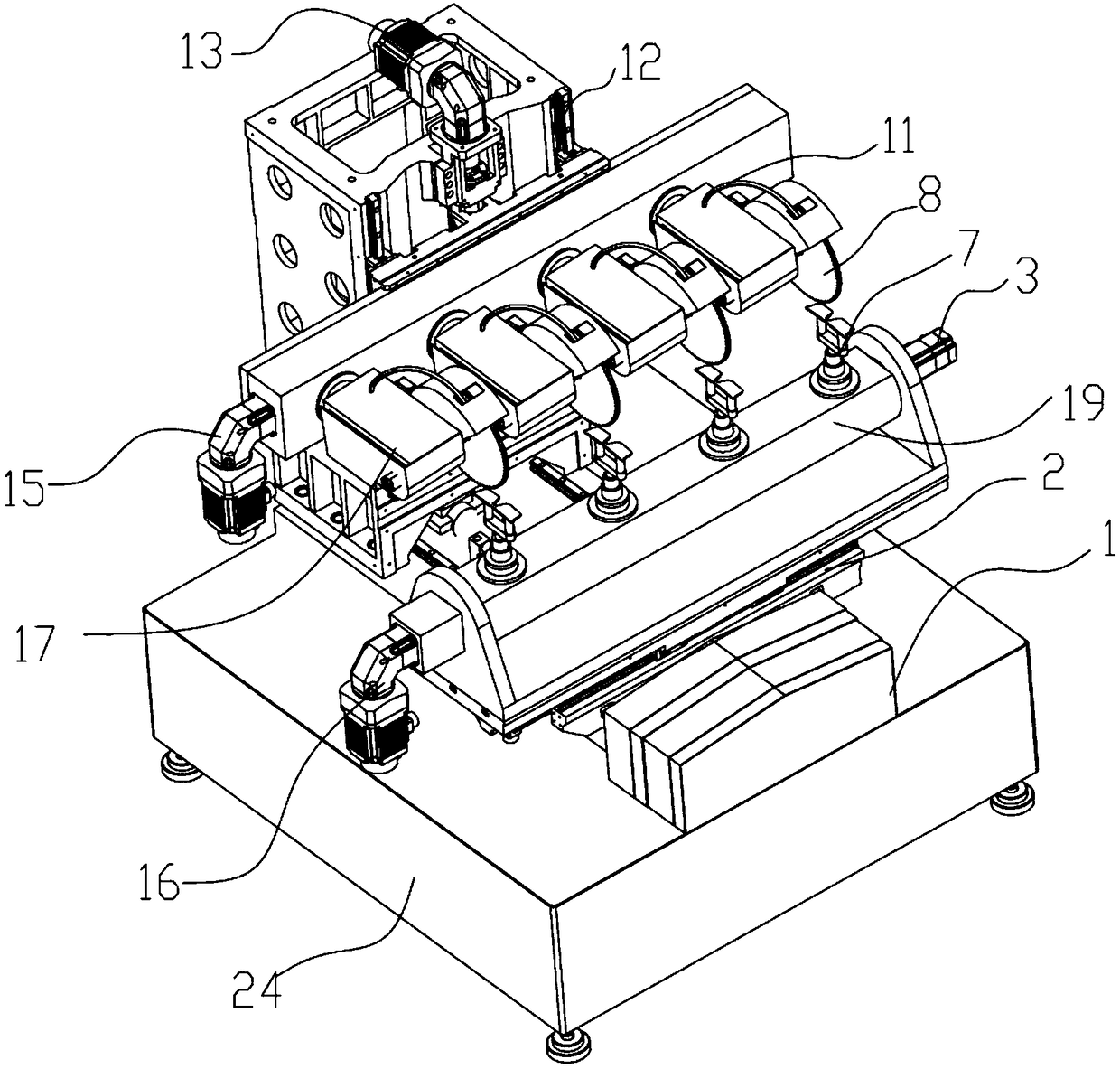

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] like Figure 1 to Figure 5 As shown, the specific embodiment of the present invention is as follows: comprising a grinding system, a workpiece motion mechanism and a drive system, the grinding system is movably connected to the vertical working guide rail 12, and is located on the workpiece motion mechanism, and the workpiece motion mechanism is located on the horizontal workbench. The drive system provides power for the grinding system, the workpiece movement mechanism, the vertical working guide rail 12 and the horizontal worktable respectively, and is connected to a control system, such as a numerical control and PLC computer control drive system;

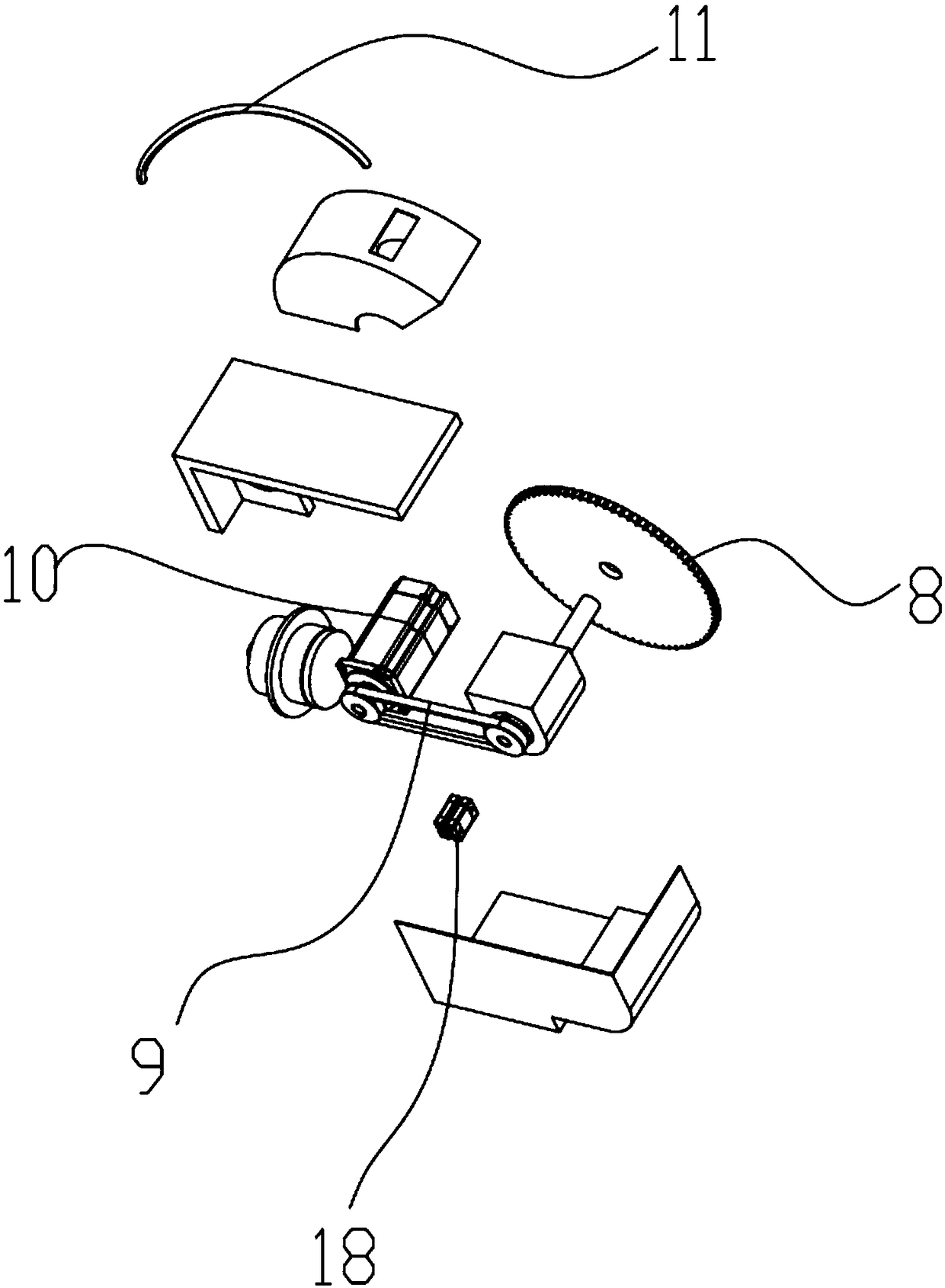

[0029] The grinding system includes a grinding wheel assembly and a rotary table assembly, and the grinding wheel assembly is connected and fixed on the rotary table 17;

[0030] The workpiece movement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com