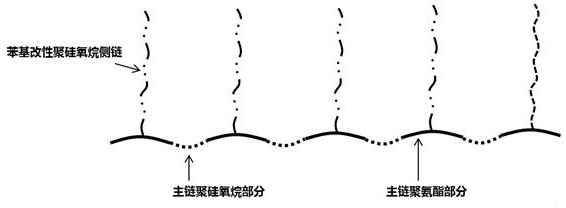

A kind of preparation method of comb structure organosilicon-polyurethane copolymer

A comb-like structure, silicone technology, applied in coatings, adhesives, etc., can solve the problems of insufficient weather resistance, poor compatibility, etc., to enhance thermal stability and weather resistance, reduce the difference in solubility parameters, and make up for performance defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]14.8 g of 5 methyldiloxane is mixed with 109.0 g of tetramethyl tetraphenylcyclo tetrahydiloxane, adding 2000 ppm sulfuric acid, heating to 60 ° C for 4 hours, over quantified sodium hydrogencarbonate and post filtration, and then 9.2 g of a propylene glycol was added, and 1 hour was reacted at 100 ° C to give a single endolytic hydroxy-blockphenyl modified silicone to be used;

[0033]59.3 g of octazetic ring tetra siloxane with 12.5 g of 1,3-bis (3-aminopropyl) -1,1,3,3-tetramethylsiloxane, 2000 ppm sulfuric acid, heated to 60 When the reaction was reacted for 6 hours, it was filtered through sodium bicarbonate to obtain an amino-sealing polysiloxane to be used;

[0034]34.8 g of toluene diisocyanate was mixed with 50.0 g of a polyhexidide diol of 50.0 g of a molecular weight of 1000, and 100 ppm triendylene diamine was added, and at 60 ° C for 3.5 hours, then the above-mentioned single-end polyhydroxy-blockphenyl group was added. The modified silicone and amino-blocking polysilox...

Embodiment 2

[0036]14.8 g of 5 methyldiloxane is mixed with 396.7 g of phenylcyclized tetra siloxane, adding 2000 ppm sulfuric acid, heating to 70 ° C for 8 hours, over quantitative sodium hydrogencarbonate and post filtration, and add to the filtrate 9.2 g of propylene glycol, 120 ° C for 2 hours, resulting in single-end polyhydroxy-blockphenyl modified polysiloxane to be used;

[0037]148.3 g of dimethylsiloxane mixed ring was mixed with 55.2 g of 1,3-bis (3-aminobutyl) -1,1,3,3-tetramethyl siloxane, and 2000 ppm sulfuric acid, heated to The reaction was reacted at 40 ° C for 8 hours, and the sodium hydrogencarbonate was filtered to give an amino-sealing polysiloxane to be used;

[0038]67.3 g of hexamethylene diisocyanate was mixed with 40.0 g of a polyethylene glycol having a molecular weight of 400 to add 200 ppm bis-(3-dimethylpropanamine) amine, reacted at 70 ° C for 2.5 hours, and added to the above obtained Single-end polyhydroxy-blocking phenyl modified silicone and amino-blocking polysiloxa...

Embodiment 3

[0040]14.8 g of 5 methyldiloxane with 163.5 g of trimethyltrimidal cycloalkane, 2000 ppm sulfuric acid, heated to 40 ° C for 6 hours, over-quantium hydrogencarbonate and post filtration, and then 9.2 g of propylene glycol was added to 110 ° C for 1 hour, and the single-ended polyhydroxy-blockphenyl modified polysiloxane is to be used;

[0041]222.3 g of a decaglatylcyclohydiloxane is mixed with 27.7 g of 1,3-bis (4-aminobutyl) tetramethylene siloxane, adding 2000 ppm sulfuric acid, heating to 70 ° C for 4 hours, sodium bicarbonate Neutralization is filtered to obtain an amino-sealing polysiloxane to be used;

[0042]75.2 g of diphenyl dimethyl diisocyanate was mixed with an 80.0 to molecular weight of 1000 of polycapralcarbonate diol, and 200 ppm three (dimethyl) amine was added, and the reaction was reacted at 80 ° C for 1.5 hours, and then the above obtained Single-ended polyhydroxy-blockphenyl modified silicone and amino-blocking polysiloxane, and 200 g of butidone for dilution, contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com