Target cooling for physical vapor deposition (pvd) processing systems

A target and substrate processing technology, applied in electrical components, metal material coating process, vacuum evaporation coating, etc., can solve problems such as aggravating target bending/deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

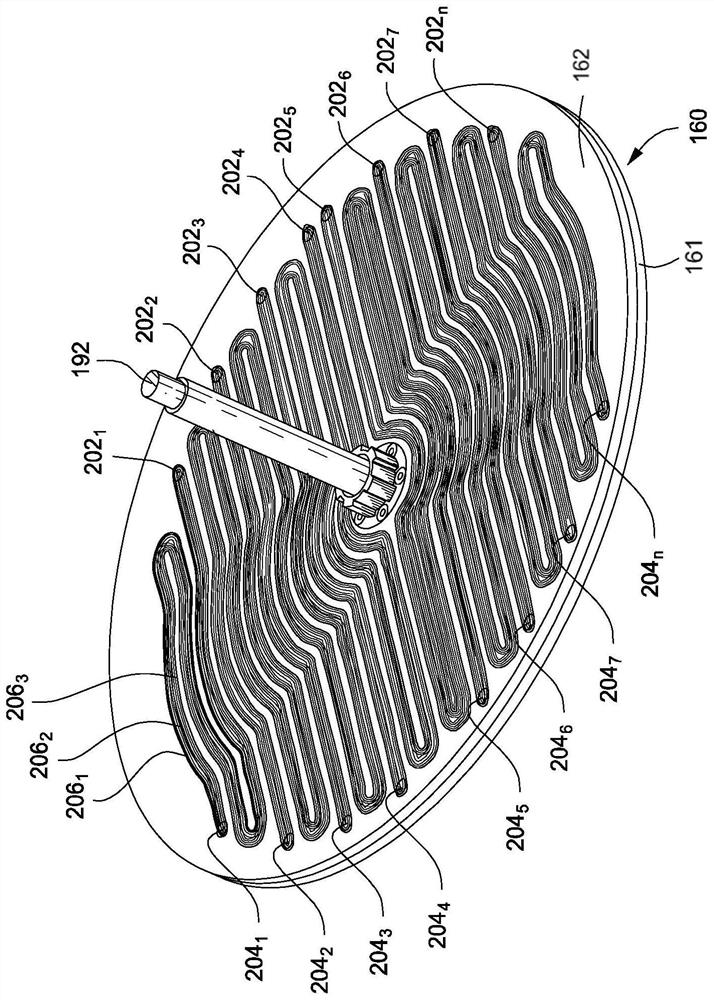

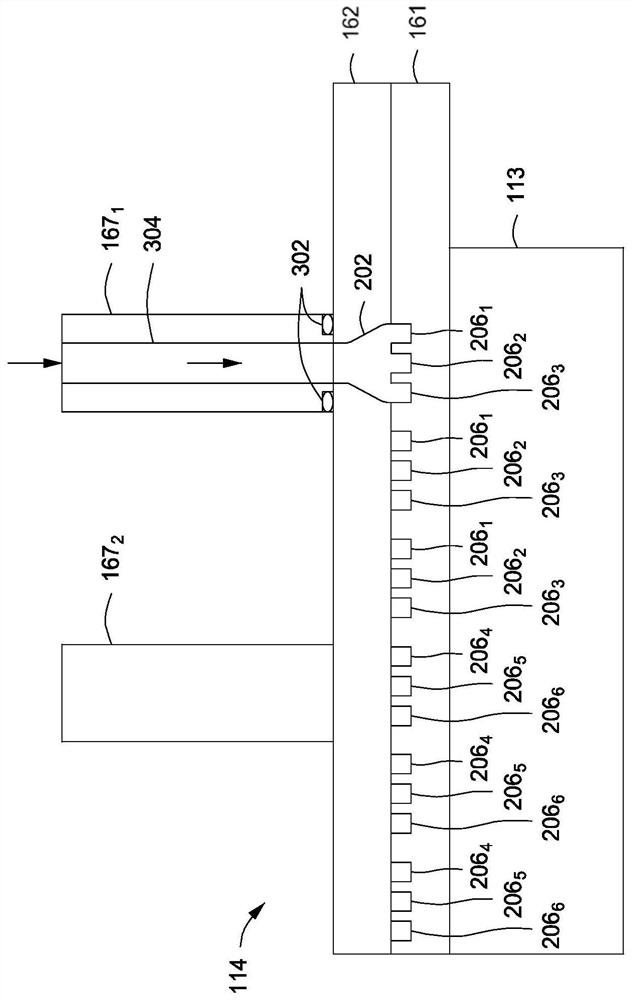

[0014] Embodiments of the present invention provide improved cooling for target assemblies used in substrate processing systems by using cooling channels through the back plate of the target. These channels allow coolant to be provided closer to the heat source (target face), thereby facilitating more efficient heat removal from the target. More efficient removal of heat from the target results in a target with smaller thermal gradients and thus less mechanical bending / deformation.

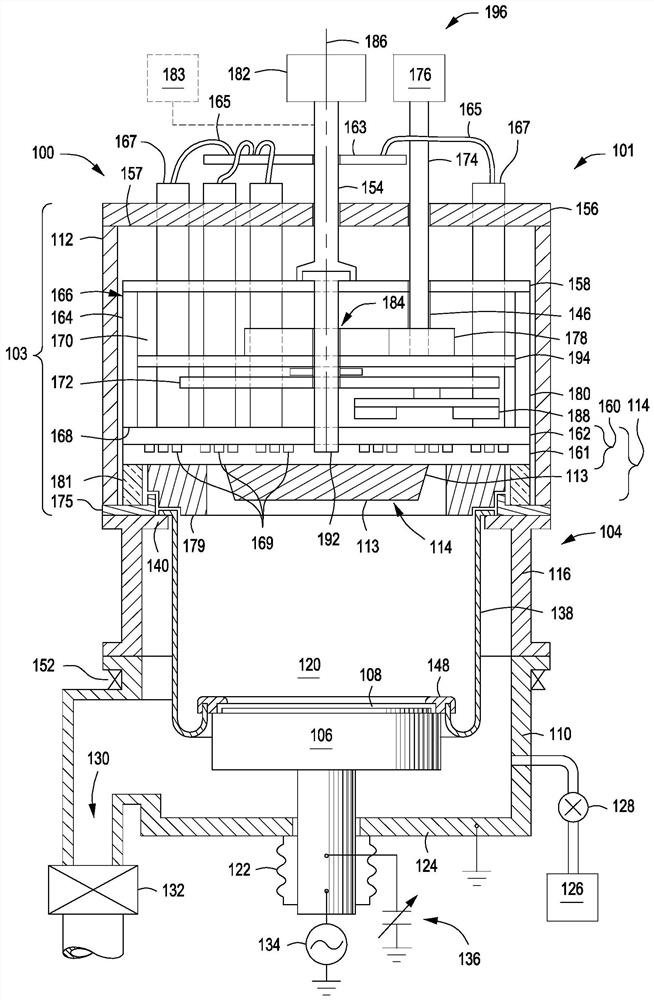

[0015] figure 1 A simplified cross-sectional view of a physical vapor deposition (PVD) processing system 100 according to some embodiments of the invention is depicted. Examples of other PVD chambers suitable for modification in accordance with the teachings provided herein include Plus and SIP PVD processing chambers, both commercially available from Applied Materials, Santa Clara, CA. Other processing chambers from Applied Materials, Inc. or other manufacturers, including those configured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com