Electroplating pen device, intelligent electrochemical coating and 3D printing device and using methods thereof

A 3D printing and electrochemical technology, applied in the field of electrochemical deposition, can solve the problems of irreparable, waste of resources, inconvenient operation, etc., and achieve the effect of preventing disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

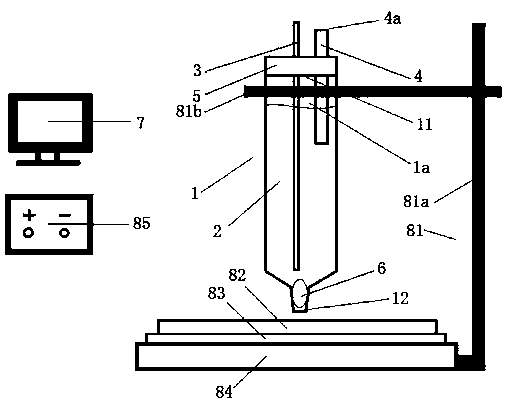

Embodiment 1

[0032] Configure 200g / L of FeSO4 7H2O solution to do electroplating solution 2, pack into the electroplating pen device, the electroplating pen device is sealed with sealing cover 5;

[0033] Get a piece of copper sheet 10cm long, 5cm wide, and 0.2mm thick as the substrate 82 to be deposited, first polish its surface, then clean its surface with 1mol / L dilute hydrochloric acid and 1mol / L sodium hydroxide solution, and then use Clean the residual liquid on the surface with alcohol, and finally dry it with nitrogen;

[0034] Use the DC power supply box 85, connect the positive electrode to the anode material copper 3, and connect the negative electrode to the copper sheet 82. The selected voltage is 4V, and the electroplating pen device is manually controlled to carry out free electrodeposition on the surface of the copper sheet 82. During this period, the liquid level of the lower leakage port 12 is kept in contact with the copper sheet 82. The copper sheets 82 are in contact; ...

Embodiment 2

[0037] Configure 200g / L of FeSO4 7H2O solution to do electroplating solution 2, pack into the electroplating pen device, the electroplating pen device is sealed with sealing cover 5;

[0038] Get a piece of copper sheet 10cm long, 5cm wide, and 0.2mm thick as the substrate 82 to be deposited, first polish its surface, then clean its surface with 1mol / L dilute hydrochloric acid and 1mol / L sodium hydroxide solution, and then use Clean the residual liquid on the surface with alcohol, and finally dry it with nitrogen;

[0039] Fix the electroplating pen device on the fixing part 81b;

[0040]Use the DC power supply box 85, connect the positive pole to the anode material copper 3, the negative pole to the copper sheet 82, select the voltage to be 4V, and control the heating of the two-way mobile platform 83 and the platform lifter 84 to move through the computer program to make the electroplating pen device drain. The liquid surface of the liquid mouth is in contact with the coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com