Defoaming cleaning method for washing machine

A washing machine and defoaming technology, which is applied in the field of washing machines, can solve the problems of unsuccessful dehydration, affecting the performance of washing machines, and the impact of dehydration work, so as to prevent residual stains and bacteria breeding, stable and reliable defoaming and cleaning work, and improve user experience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

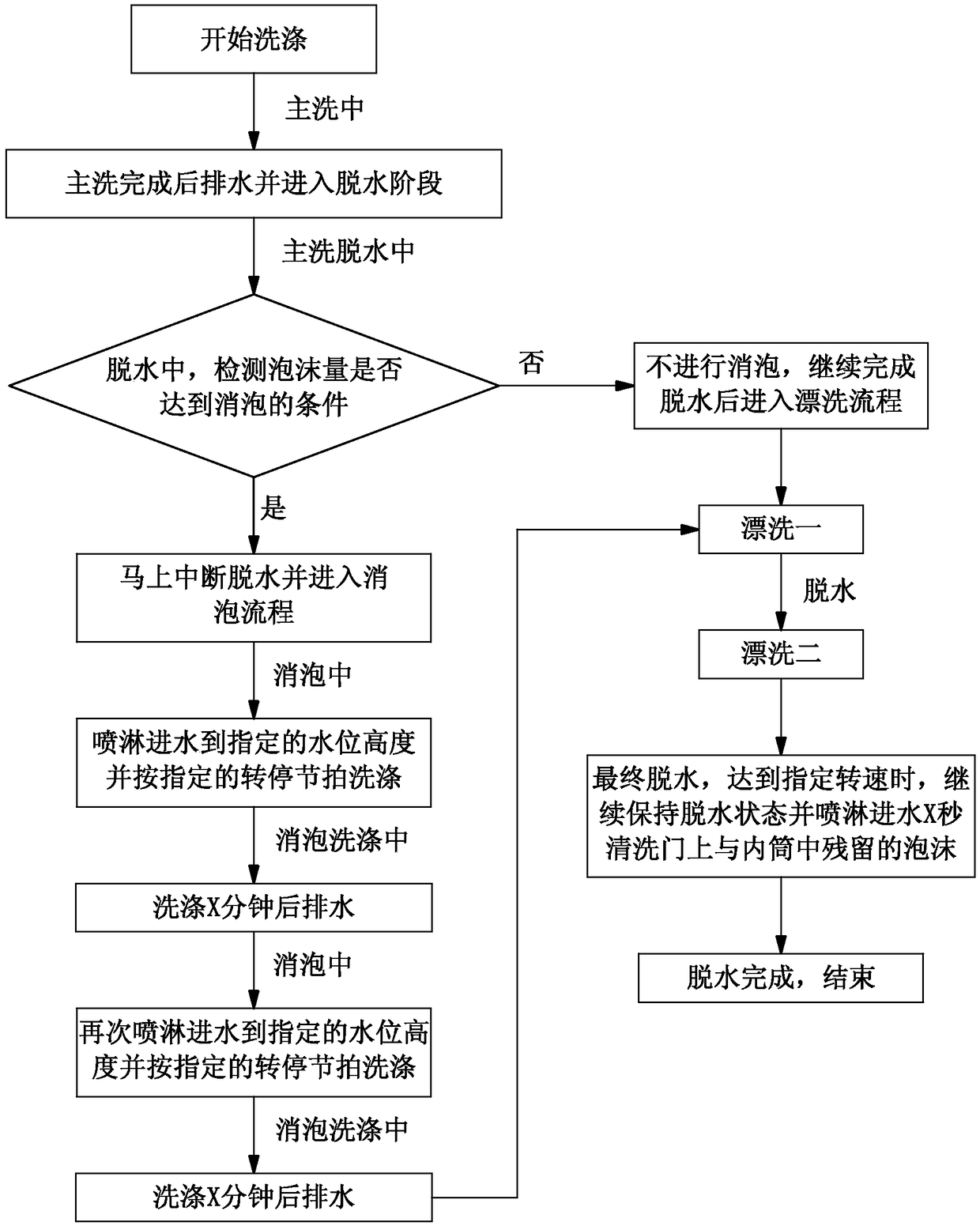

[0023] see figure 1 , the defoaming cleaning method of the washing machine, comprising the following steps:

[0024] (a) The washing machine starts to execute the preset basic washing process until the main washing process is completed, drains water and enters the dehydration process;

[0025] (b) During the dehydration process, check whether the water level frequency reaches the preset defoaming value according to the algorithm, and if the preset defoaming value is reached, then terminate the dehydration process and enter the defoaming stage, so as to achieve the purpose of determining whether to defoam;

[0026] (c) Use the spray method to enter the water to the specified water level and execute the specified rotation and stop cycle to wash for X minutes and then drain until the defoaming value drops to the specified value;

[0027] (d) After the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com