A kind of preparation method of polyurethane polymer elastomer composite mesh material

A polymer elastomer, polyurethane technology, used in textiles, papermaking, clothing, footwear, etc., can solve the problems of mesh cloth waterproof, windproof performance, wear resistance, poor durability, harsh use conditions, etc. The effect of normal temperature and low temperature flexural performance, improving flexibility and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The mesh cloth D20F-05 is a mesh cloth normally sold in the market; the polyurethane resins A, B, C, and D are products of Hefei Amway Polyurethane New Material Co., Ltd; It is a product of Dow Corning; the leveling agent LT-7110 is a product of Hefei Amway Polyurethane New Material Co., Ltd.; the colorants are commercially available products.

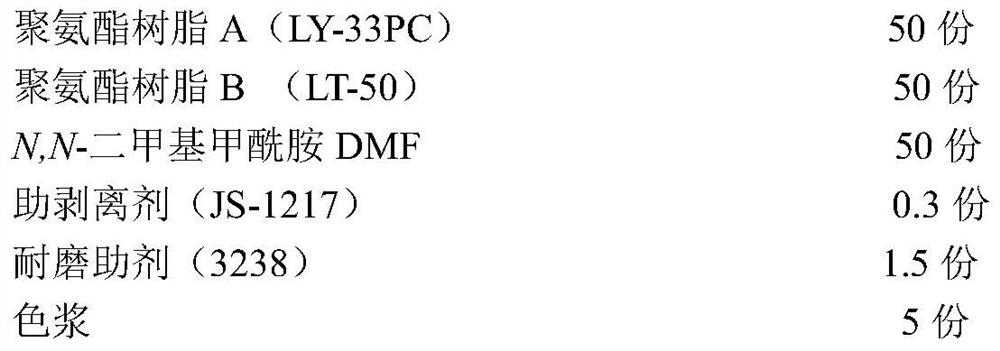

[0041] The polyurethane polymer elastomer composite mesh material in this embodiment includes a surface layer, an intermediate layer, and an adhesive layer, as well as a corresponding high-temperature negative-pressure embossing molding process. The polyurethane surface layer resin A is LY-33PC resin, the polyurethane surface layer resin B is LT-50 resin, the polyurethane intermediate layer resin is LT-8045 resin, the polyurethane adhesive layer resin is LA-7020, and the surface layer resin A and resin B according to the composition of mass parts 1:1.

[0042] The preparation method of polyurethane polymer elastomer composite m...

Embodiment 2

[0056] The mesh cloth D20F-05 is a mesh cloth normally sold in the market; the polyurethane resins A, B, C, and D are products of Hefei Amway Polyurethane New Material Co., Ltd; It is a product of Dow Corning; the leveling agent LT-7110 is a product of Hefei Amway Polyurethane New Material Co., Ltd.; the color pastes are all commercially available products;

[0057] The polyurethane polymer elastomer composite mesh material in this embodiment includes a surface layer, an intermediate layer, and an adhesive layer, as well as a corresponding high-temperature negative-pressure embossing molding process. The polyurethane surface layer resin A is LY-60PC resin, the polyurethane surface layer resin B is LT-80 resin, the polyurethane intermediate layer resin is LT-8045 resin, the polyurethane bonding layer resin is LA-7050, and the surface layer resin A and resin B according to the composition of mass parts 1:1.

[0058] The preparation method of polyurethane polymer elastomer composi...

Embodiment 3

[0072] The mesh cloth D20F-05 is a mesh cloth normally sold in the market; the polyurethane resins A, B, C, and D are products of Hefei Amway Polyurethane New Material Co., Ltd; It is a product of Dow Corning; the leveling agent LT-7110 is a product of Hefei Amway Polyurethane New Material Co., Ltd.; the color pastes are all commercially available products;

[0073] The polyurethane polymer elastomer composite mesh material in this embodiment includes a surface layer, an intermediate layer, and an adhesive layer, as well as a corresponding high-temperature negative-pressure embossing molding process. The polyurethane surface layer resin A is LY-70PC resin, the polyurethane surface layer resin B is LT-8035F resin, the polyurethane intermediate layer resin is LT-8045 resin, the polyurethane bonding layer resin is LA-2068, and the surface layer resin A and resin B according to the composition of mass parts 1:1.

[0074] The preparation method of polyurethane polymer elastomer co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com