Laser remelting method for plasma cathode electrolytic deposition ceramic coating surface

A plasma and ceramic coating technology, which is applied in surface reaction electrolytic coating, electrolytic coating, electrolytic inorganic material coating, etc. problems, to achieve the effect of improving structural compactness, increasing surface hardness, and reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Titanium-aluminum alloy is selected as the base material and processed according to the following steps:

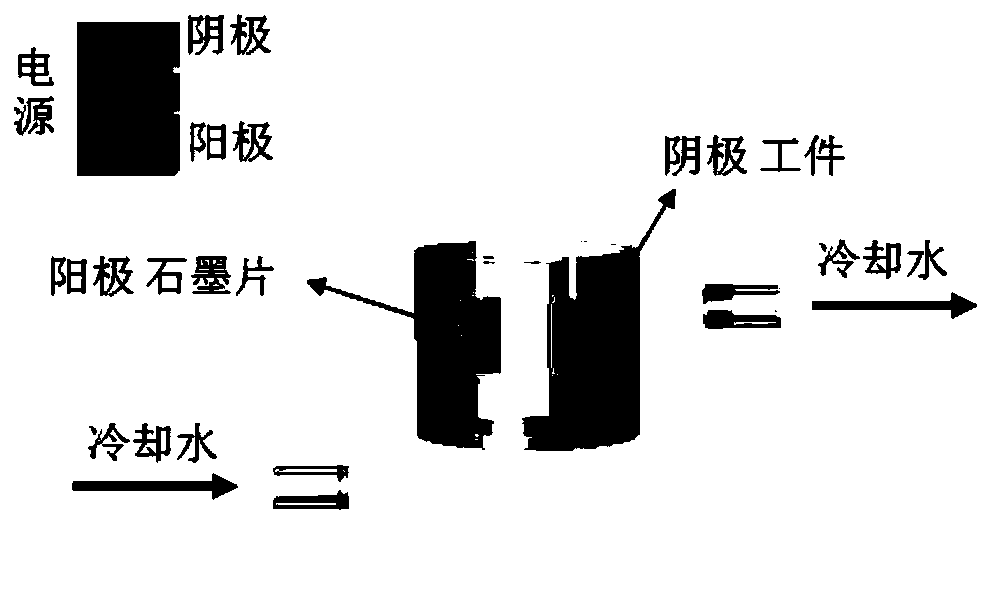

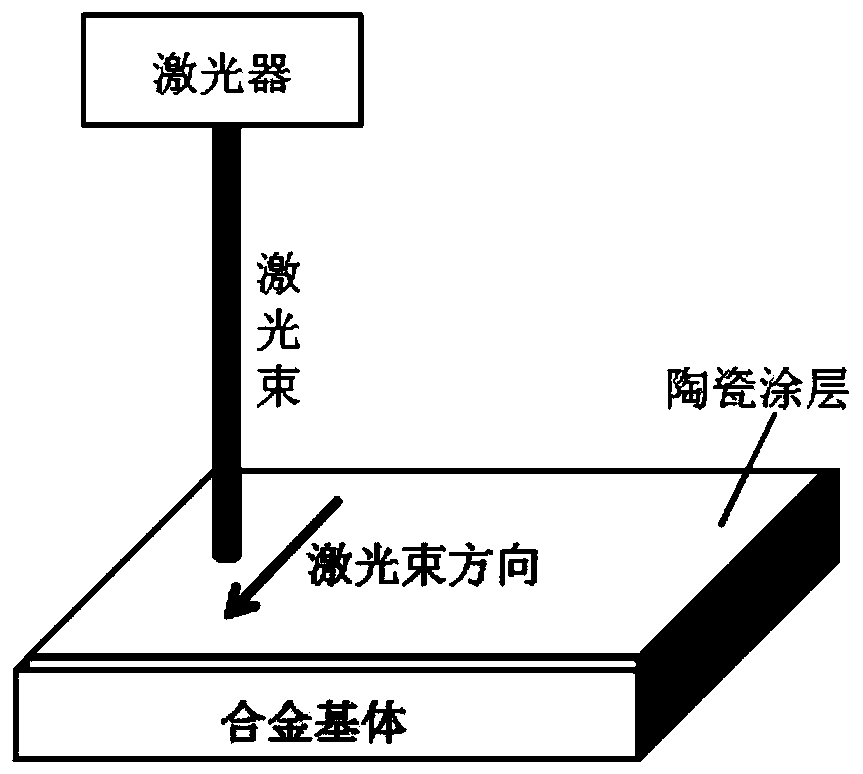

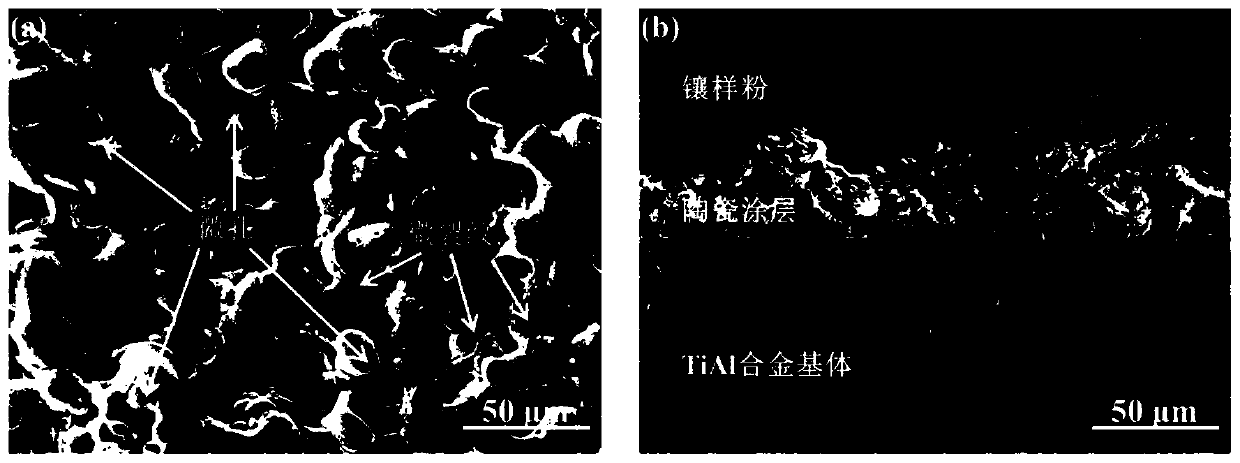

[0049] 1. Pretreatment of the substrate material: choose 50# sandpaper-400# sandpaper to polish the alloy substrate, remove the oil stain and rust layer on the surface of the substrate, rinse the polished substrate material with deionized water, and use acetone or absolute ethanol Ultrasonic cleaning for 3min–5min, then rinse with deionized water, and air dry naturally. The alloy matrix sample is used as the anode, and the stainless steel sheet is used as the cathode. The plasma power supply is used for micro-arc oxidation treatment, and the plasma micro-arc oxidation power supply is used for micro-arc oxidation treatment. The working fluid composition is: Na 2 SiO 3 3g / L–30g / L, NaAlO 2 2g / L–20g / L, Na 3 PO 4 2g / L–30g / L, NaOH 1g / L–5g / L, the process parameters are: frequency 500Hz, duty cycle 20%, current density 5A / dm 2 , temperature 10°C, time 5min. Rinse ...

Embodiment 2

[0070] The difference between this embodiment and embodiment 1 is that the base material described in step 1 is titanium and titanium alloy, aluminum and aluminum alloy, magnesium and magnesium alloy or stainless steel.

[0071] Other implementation steps are the same as in Example 1.

Embodiment 3

[0073] The difference between this embodiment and embodiment 1 or 2 is: in the deionized water / ethanol solvent described in step 2, the volume ratio of deionized water and ethanol is 0 / 10, 1 / 9, 2 / 8, 3 / 7, 4 / 6, 6 / 4, 7 / 3, 8 / 2, 9 / 1, 10 / 0.

[0074] Other implementation steps are identical with embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com