Novel production method of PVC antistatic fabric

A production method and antistatic technology, applied in textiles and papermaking, etc., can solve the problems of air bubbles, pinholes, and poor dispersion of antistatic agents, and achieve simple operation, reduce uncontrollable factors, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

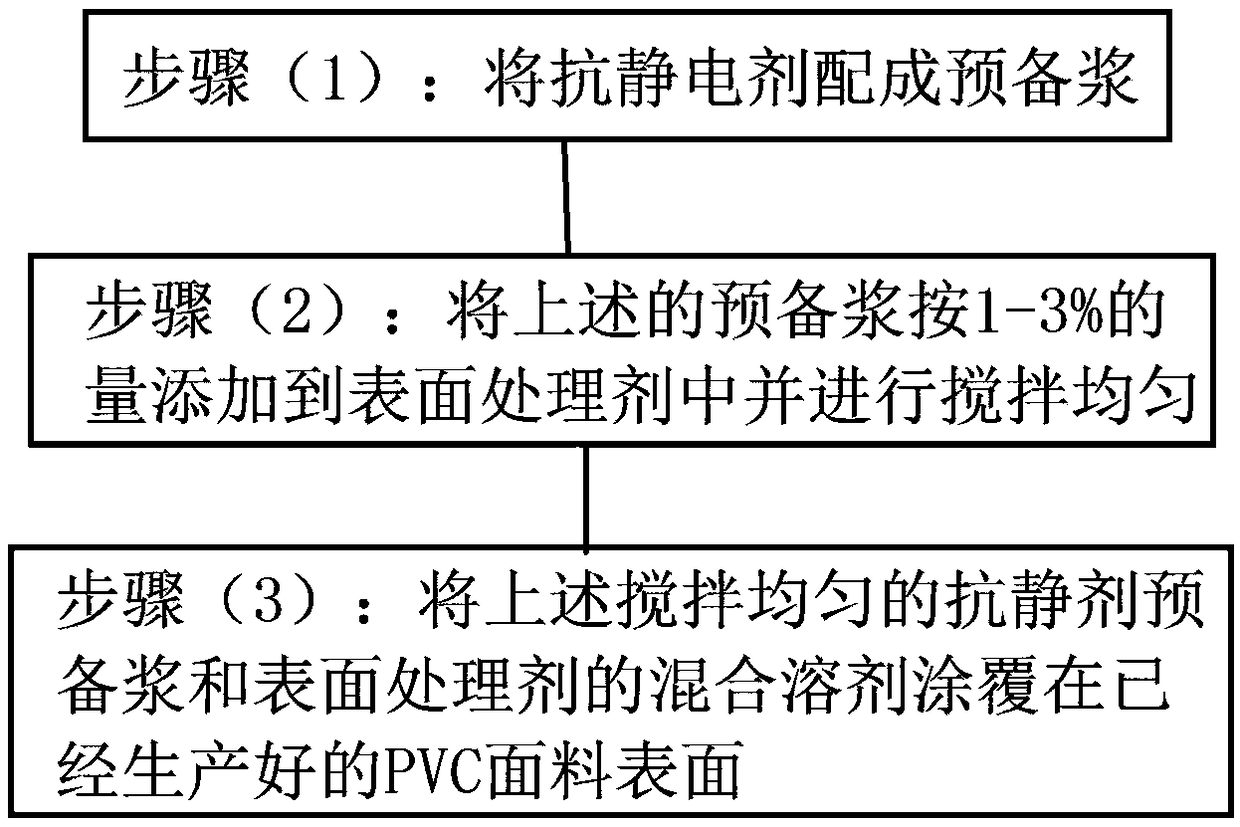

[0026] The new production method of PVC antistatic fabric comprises the following steps:

[0027] Step (1): preparing the antistatic agent into a preparation slurry;

[0028] Step (2): Add the above-mentioned preparatory slurry to the surface treatment agent in an amount of 1-3% and stir evenly. A dispersant is added during the stirring process. The surface treatment agent is polyvinylidene fluoride or polymethyl Methyl acrylate, wherein the antistatic agent is any antistatic agent that is effectively compatible with the surface treatment agent;

[0029] Step (3): Coat the mixed solvent of the above-mentioned uniformly stirred antistatic agent preparatory slurry and surface treatment agent on the surface of the produced PVC fabric, and keep mixing in the trough through the internal circulation device during the coating process Solvent stirring. The present invention utilizes that antistatic agent can be compatible with polyvinylidene fluoride or polymethacrylic acid methyl s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap