Rectangular steel boxes for uniform-thickness cement-soil stirring wall and construction method

A cement-soil mixing wall and cement-soil wall technology, which is applied in excavation, foundation structure engineering, construction, etc., can solve the problems of large deformation of foundation pit, low section utilization rate, and low rigidity, so as to reduce water leakage and improve wall Body stiffness, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the drawings and embodiments.

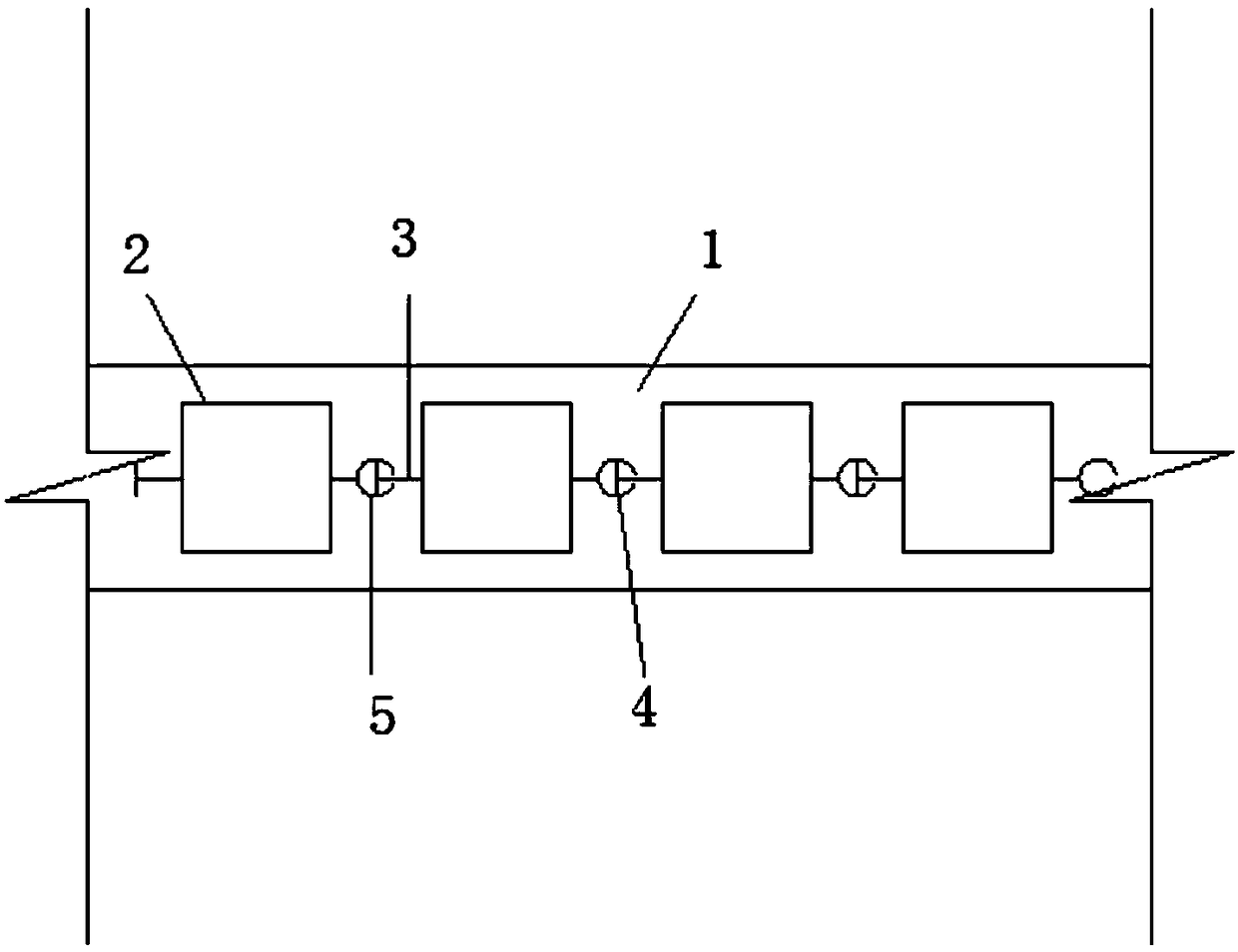

[0021] Such as figure 1 As shown, a rectangular steel box used in a cement-soil mixing wall of equal thickness is composed of a rectangular steel box 2, a connecting steel plate 3, a female joint 5, a male joint 4, and the like. A plurality of rectangular steel boxes 2 are connected into a whole by connecting steel plates 3, and inserted into the cement-soil wall 1 to form an underground cement-soil continuous wall, which serves as the enclosure structure of the foundation pit. The connecting steel plates 3 of the adjacent rectangular steel boxes are connected by a female joint 5 and a male joint 4 welded on the connecting steel plates 3 in cooperation. The female and male joints of the rectangular steel box 2 extend the penetration path of groundwater and reduce the leakage of the foundation pit.

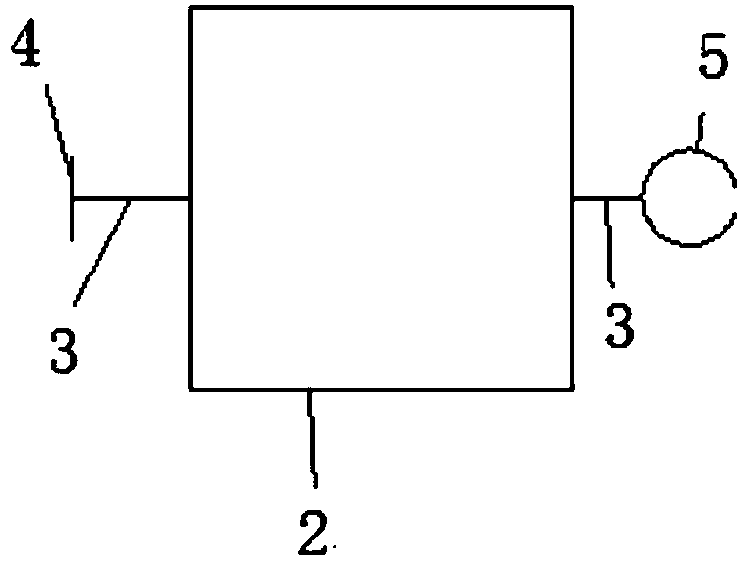

[0022] Such as figure 2 As shown, the rectangular steel box 2 is proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com