Shunting system with pneumatic shunting well and control method

A diverting system and diverting well technology, applied in waterway systems, sewage removal, drainage structures, etc., can solve the problem of high cost of electronically controlled hydraulic control, and achieve mature and reliable prices, cost savings, and low costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A diversion system with a pneumatic diversion well 40, used to divert the fluid in the drainage pipe, wherein the drainage pipe is a drainage pipe in a confluence system, a diversion system or a mixed flow area or in front of an outlet near a natural water body piping, including:

[0073] Compressed gas source 10, used to provide compressed gas;

[0074] Gas delivery pipe, the gas delivery pipeline is used to deliver gas;

[0075] Pneumatic diverter well 40,

[0076] The pneumatic diversion well 40 includes a well body structure and at least an inlet 411 arranged on the well body structure, a first water outlet pipe 413, a second water outlet pipe 412 and a pneumatic shut-off device arranged on the second water outlet pipe 412, which is the second water outlet pipe 412. Two pneumatic shut-off devices 422, wherein the inlet 411 is connected to the drainage pipe upstream of the pneumatic diversion well 40, the first water outlet pipe 413 is connected to the rainwater pi...

Embodiment 2

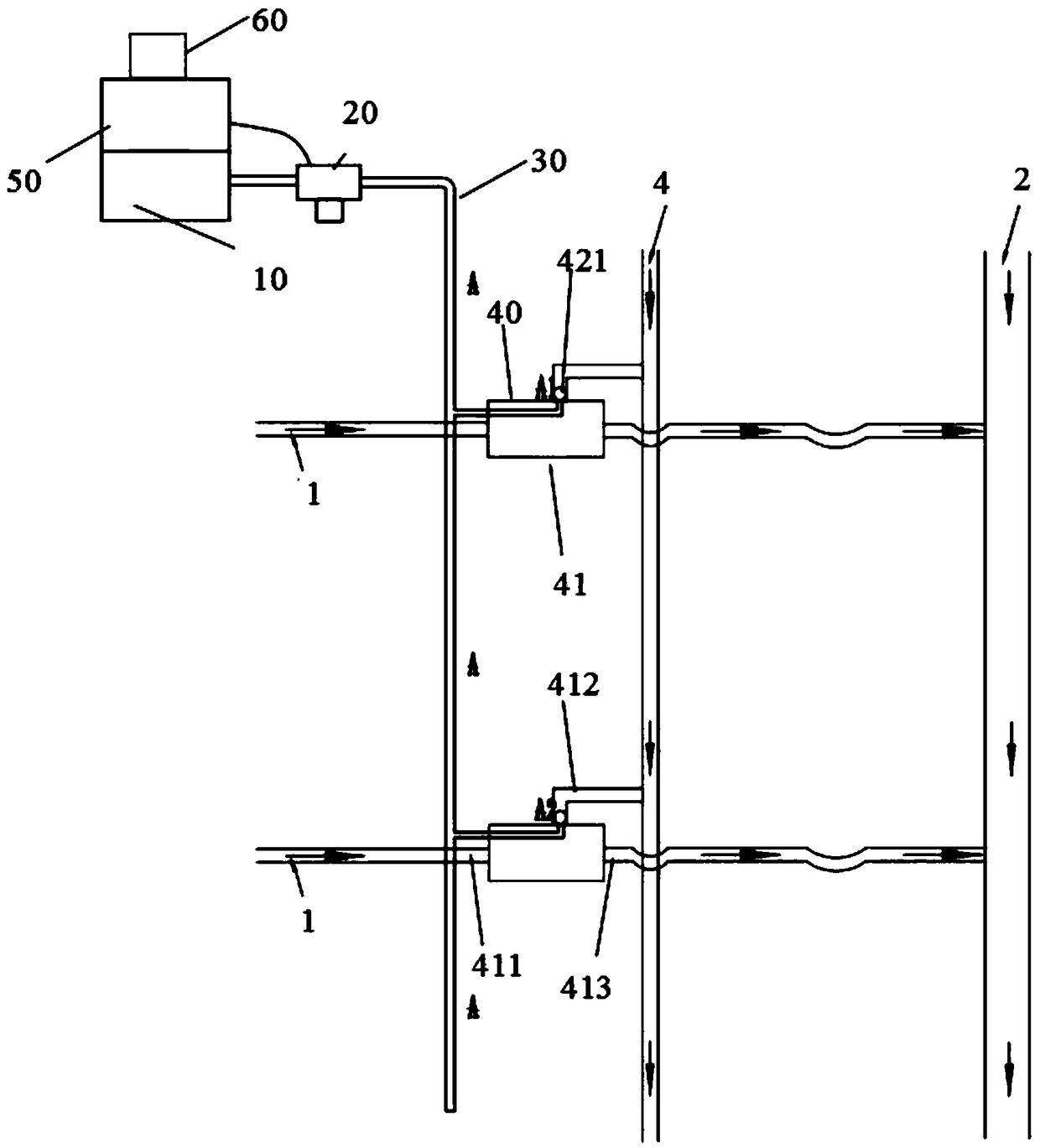

[0112] figure 1 It is a schematic structural diagram of a one-input and two-outlet cell distribution system applied to a distribution system cell, a combination system cell or a mixed flow system cell according to an embodiment of the present invention.

[0113] see figure 1 As shown, the form of the pneumatic diversion well is form one, including compressed gas source 10, control valve 20, gas delivery main pipe 30, pneumatic diversion well 40, controller 50, measuring instrument 60, rainwater pipe and sewage pipe 4 through the outlet pipe 1. The sewage intercepting pipe 3 communicates with the pneumatic shunt well 40 .

[0114] A compressed gas source 10 is used to provide compressed gas. In this embodiment, the compressed gas source is an air compressor, which is set in the control room of the community.

[0115] The control valve 20 is connected with the compressed gas source at the inlet. When an air bag or a pneumatic pipe pinch valve structure is arranged in the pneum...

Embodiment 3

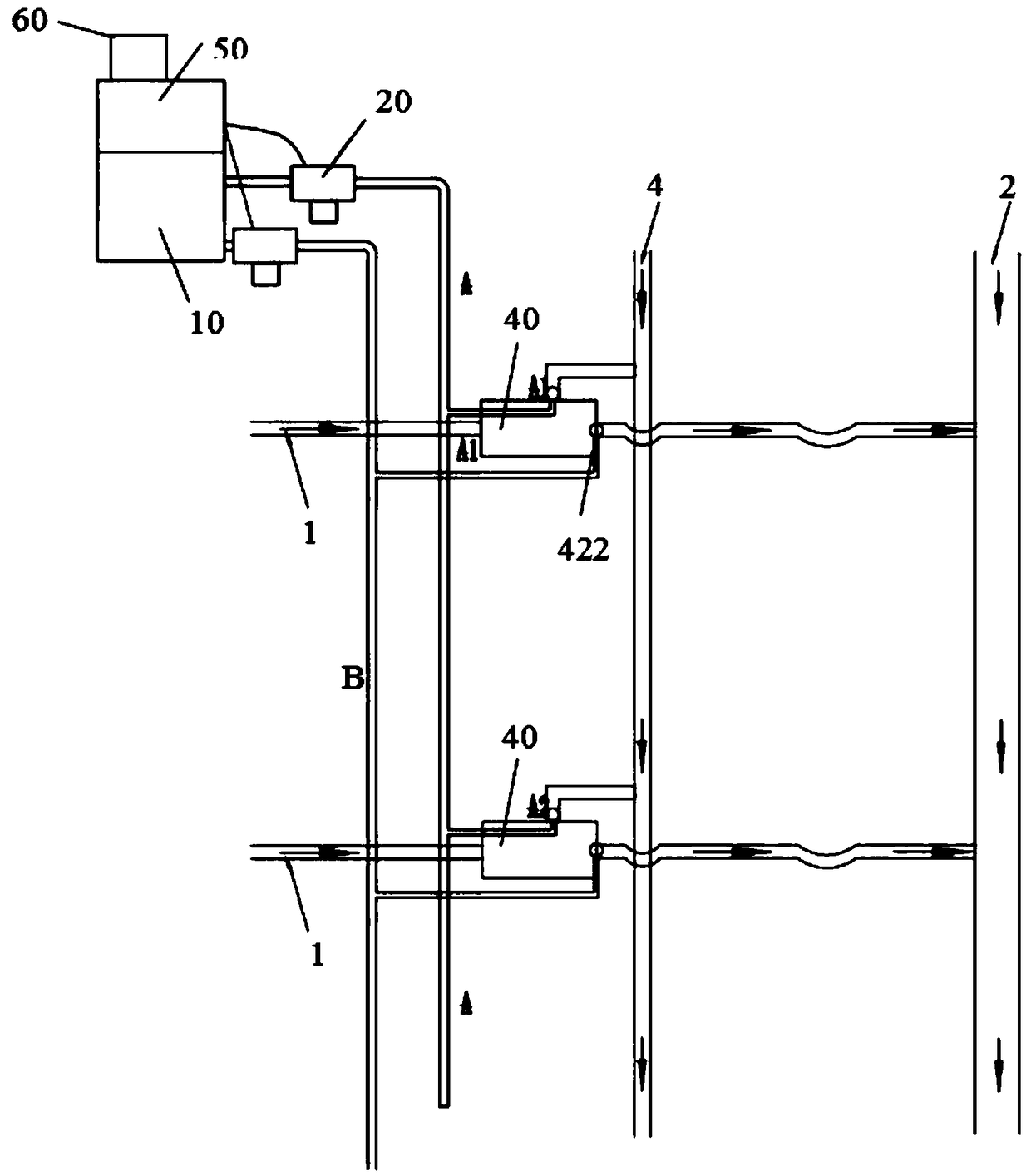

[0125] figure 2 It is a schematic structural diagram of a one-inlet and two-outlet community distribution system in Embodiment 3 of the present invention. The form of the pneumatic splitter well in this embodiment is form two.

[0126] Such as figure 2 As shown, the difference between the present embodiment and the second embodiment is that two pneumatic shut-off devices are respectively provided at the first water outlet pipe 413 and the second water outlet pipe 412 of the pneumatic diverter well, respectively the first pneumatic shut-off device 421 and the second pneumatic shut-off device. The shut-off device 422, its pneumatic shut-off device selects air bag or pneumatic pipe pinch valve for use. Correspondingly, two control valves should be set: the first control valve and the second control valve, and the number of gas delivery main pipes is also two: the first gas delivery main pipe and the second gas delivery main pipe, and the first control valve controls The firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com