Tunnel top waterproof structure and implementation method thereof

A technology for waterproof structures and tunnels, applied in tunnels, tunnel linings, earth-moving drilling, etc., can solve problems such as water leakage, and achieve the effect of high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

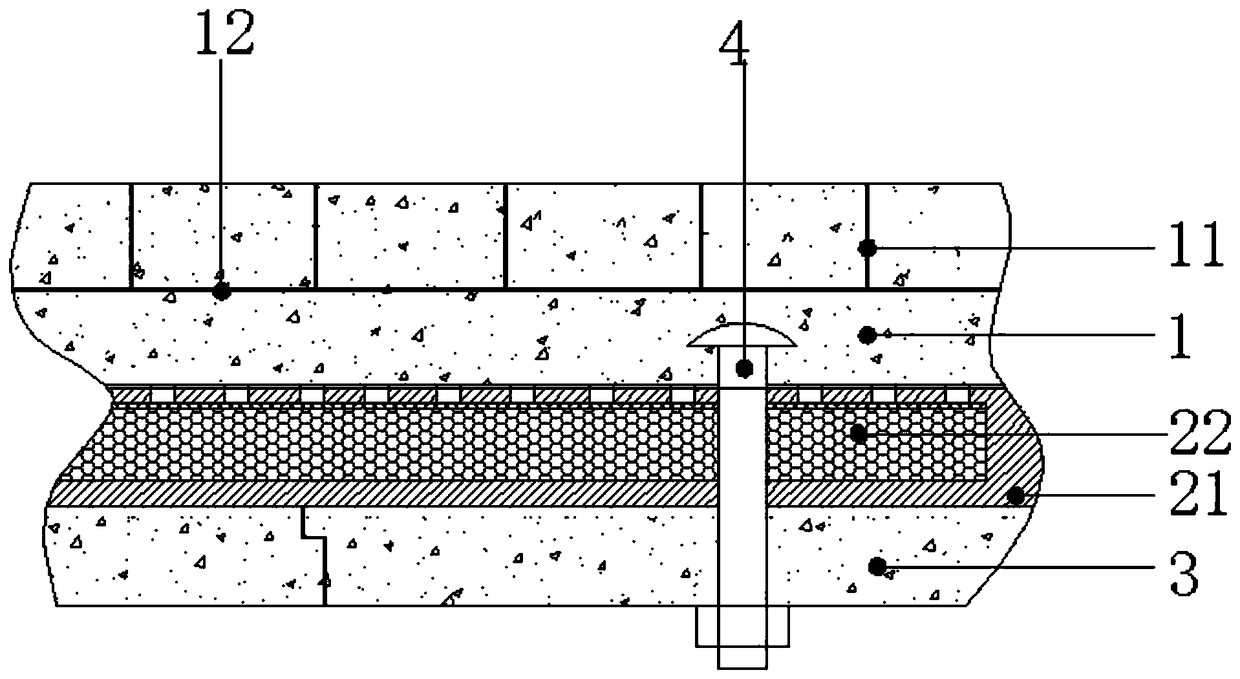

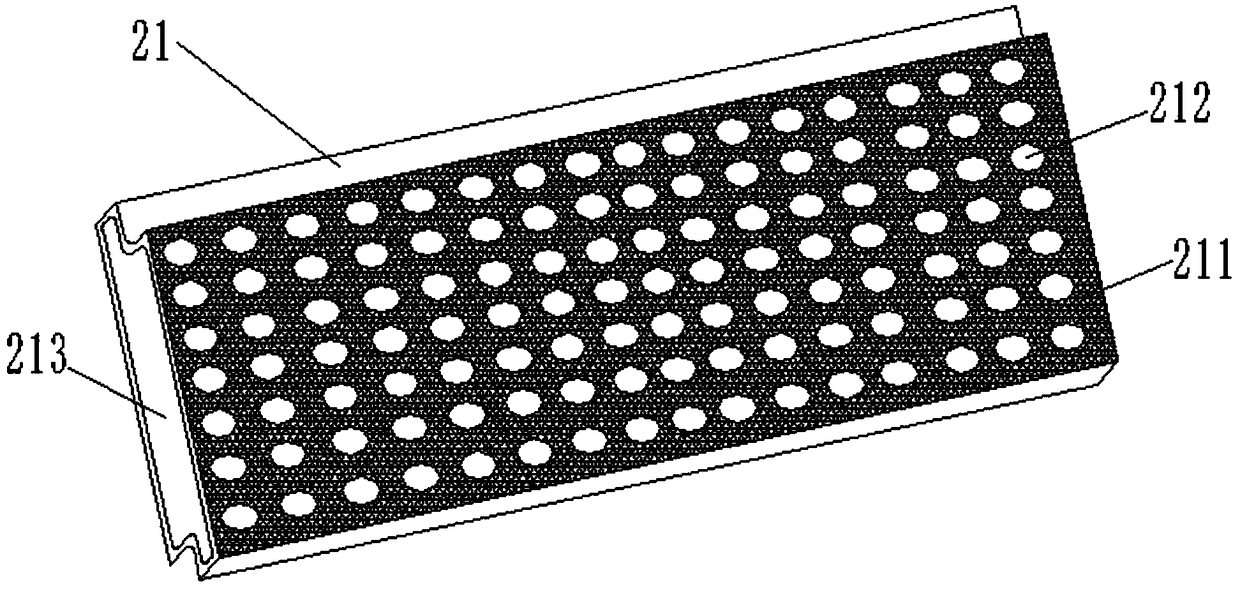

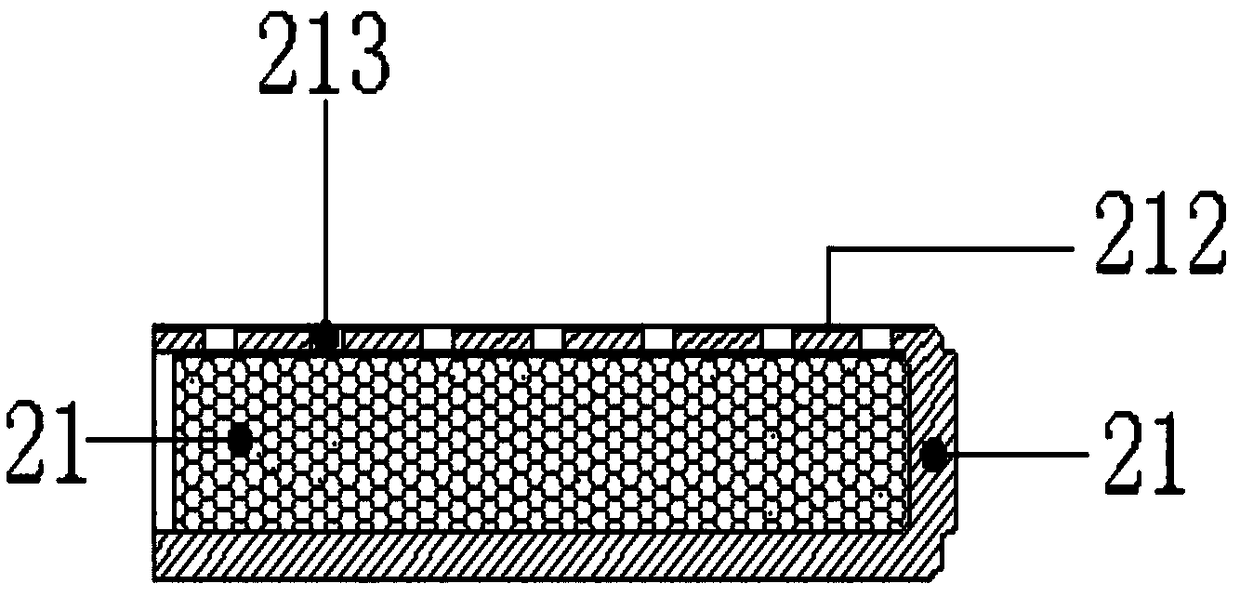

[0045] combine figure 1 , figure 2 with image 3It shows a waterproof structure at the top of the tunnel, including a concrete layer 1 in contact with the plain soil at the top of the tunnel, a waterproof structure layer and a structural support layer 3, wherein: the concrete layer 1 is formed by mixing acrylic waterproof material, concrete and defoaming agent Complete, can play the waterproof of the first layer of wall. The concrete layer 1 is connected to the plain soil as a whole by providing a longitudinal anchor bar 11 and a frame anchor bar 12. The longitudinal anchor bar 11 is fixedly connected inside the plain soil and protrudes a part, and the frame anchor bar 12 is 100-150mm away from the plain soil The protruding part of the longitudinal anchor bar 11 is welded into a mesh structure, which increases the connection force between the concrete layer 1 and the plain soil, and prevents the concrete layer 1 from falling off; the concrete layer 1 is pre-embedded with me...

Embodiment 2

[0047] The invention also discloses a method for implementing the waterproof structure at the top of the tunnel, which includes the following steps:

[0048] Step 1. Construct the concrete layer 1

[0049] E1. Flatten the degradable film on the top of the tunnel;

[0050] E2. Fix the longitudinal anchor bar 11 through the degradable film in the plain soil at the top of the tunnel, and at the same time, overlap or weld the frame anchor bar 12 with the longitudinal anchor bar 11 at a distance of 100-150 mm from the plain soil to form a frame support network;

[0051] E3. Spray the concrete once on the frame support net through the concrete pump to form the concrete layer 1, and at the same time, pre-bury one end of the bolt 4 inside the concrete layer 1 according to the design size of the drawing;

[0052] E4. Leveling the concrete layer 1 by using a pre-made steel plate with a U-shaped cross-section. Before the leveling process, cover the upper surface of the steel plate with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com