Method for detecting interface pressure of medium-voltage cold-shrinkable cable joint

A technology for cable joints and detection methods, which is applied to force/torque/power measuring instruments, measuring devices, instruments, etc., can solve problems such as heavy workload, inability to achieve simple and convenient measurement of cable joint interface pressure, and uneven electric field, etc. To achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

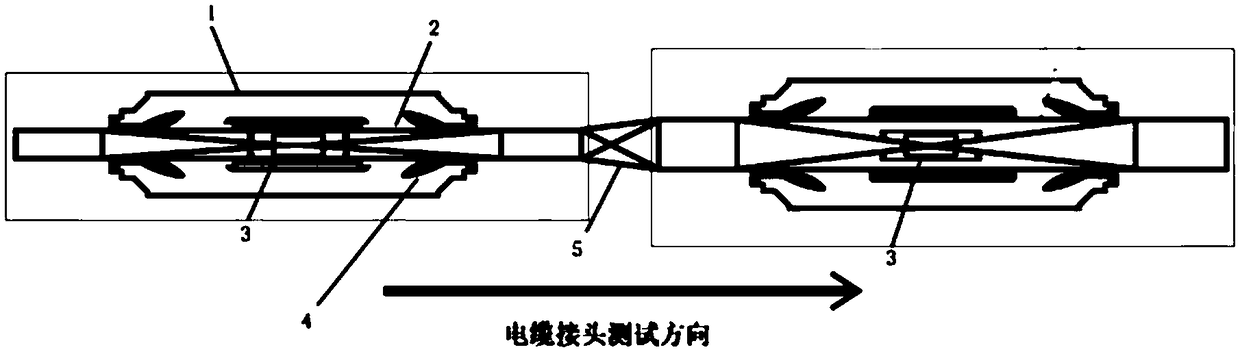

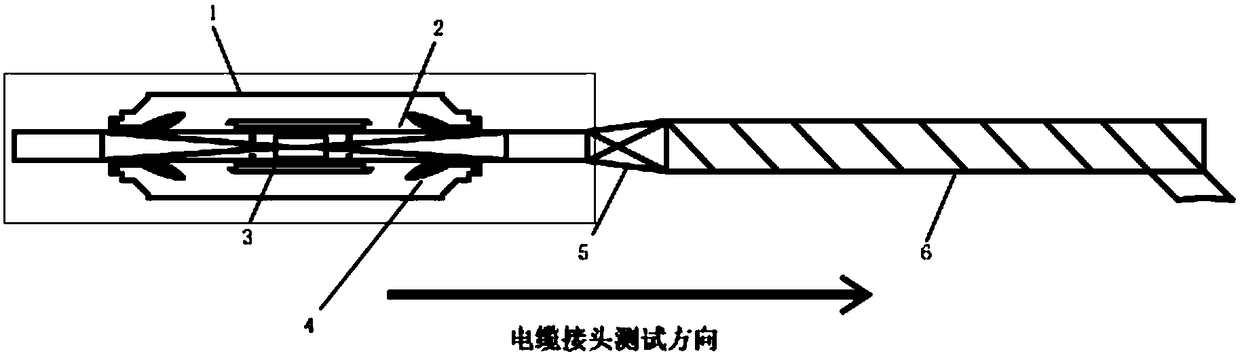

[0026] The invention provides a method for detecting the interface pressure of a medium-pressure cold-shrinkable cable joint. The method utilizes several cable core sample sections with standard cross-sections. Such as figure 1 As shown, a film-type pressure sensor 4 is installed on the surface of each cable core sample section 2, and the cable core sample sections 2 are reliably connected in sequence from small to large cross-sections through a connecting pipe 5 with a certain slope. The tail end of the connecting pipe 5 is provided with a cold-shrinkable accessory support sleeve 6, and the cable joint 1 is pushed from thin to thick to each cable core sample section 2 by a hydraulic press for pressure distribution testing, and finally pushed to the cold-shrinkable accessory support sleeve 6. Restore ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com