Feedback control method and system for electronic accelerator irradiation system

An electron accelerator and feedback control technology, applied in irradiation devices, nuclear engineering, etc., can solve problems such as stability and accuracy of drift irradiation products, unstable beam current value, and high-precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with embodiment, further illustrate the present invention.

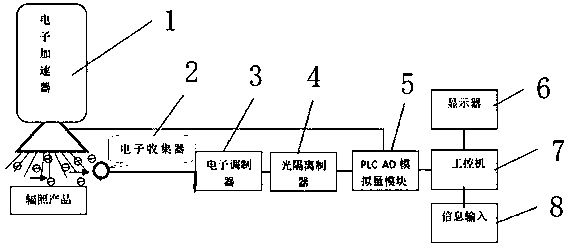

[0035] see figure 1 , figure 2 , image 3 It can be seen that a feedback control method for an irradiation system of an electron accelerator 1 according to the present invention comprises the following steps:

[0036] (1) Use the electron collector 2 to irradiate the electron beam accelerated by the accelerator onto the product and the electron collector 2 arranged around the product, and collect the scattered electrons through the electron collector 2;

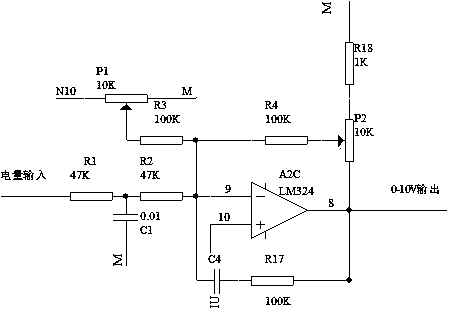

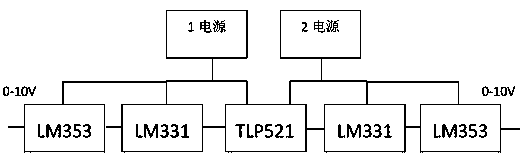

[0037] (2) The collected power is transmitted to the ML324 integrated module through the double-shielded radiation-resistant power transmission line 11 through the current-limiting resistor. After the current-limiting resistor limits the excessive power, it is amplified and adjusted by the ML324 integrated module to become a voltage signal of 0-10v ;The 0-10V voltage signal is adjusted by the LF353 integrated module and then input to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com