Intelligent partial discharge inspection robot

An inspection robot and partial discharge detection technology, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as high cost, multiple partial discharge detection equipment, and personnel safety cannot be guaranteed, so as to achieve strong reference and reduce Data processing workload, effects of avoiding personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

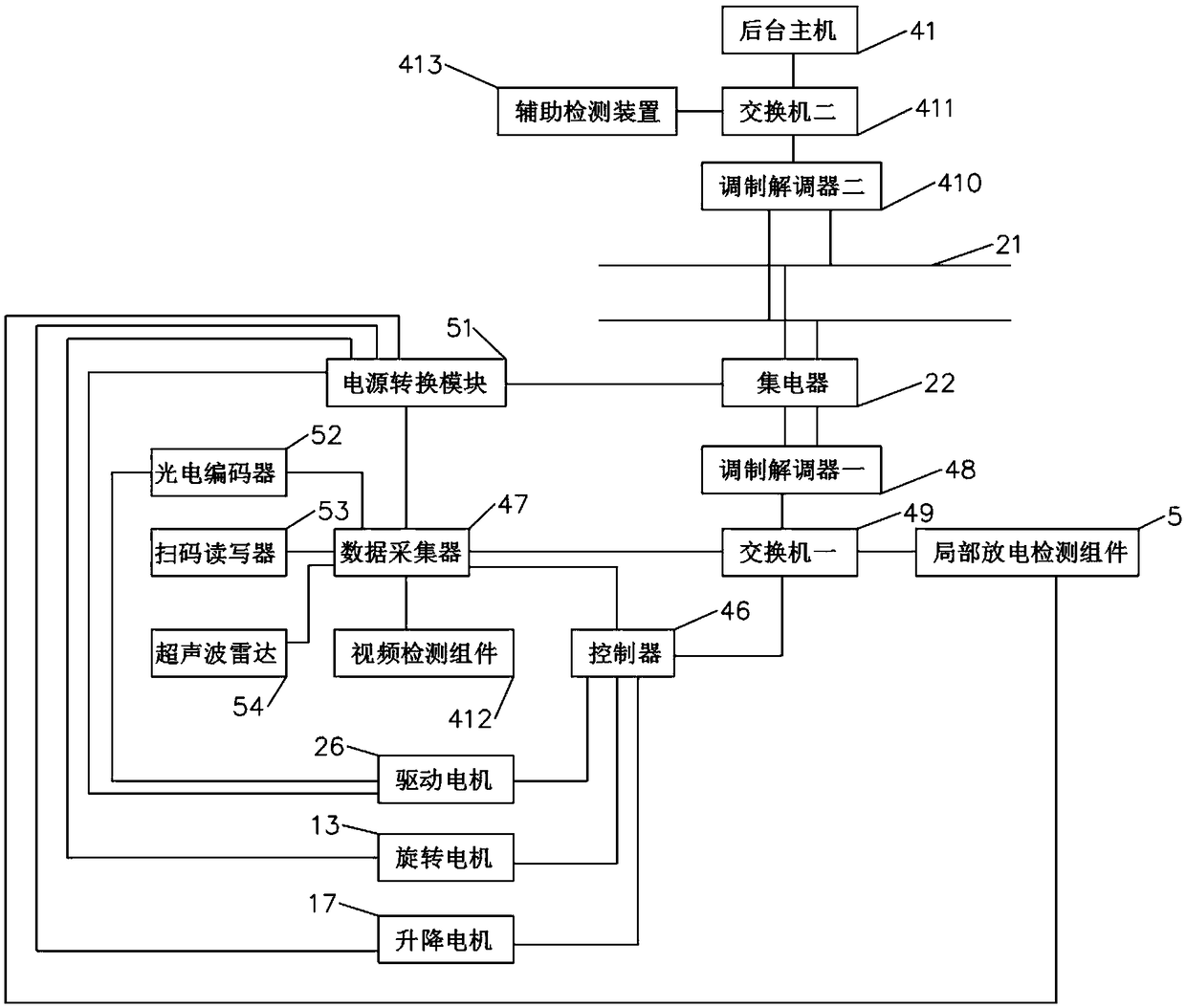

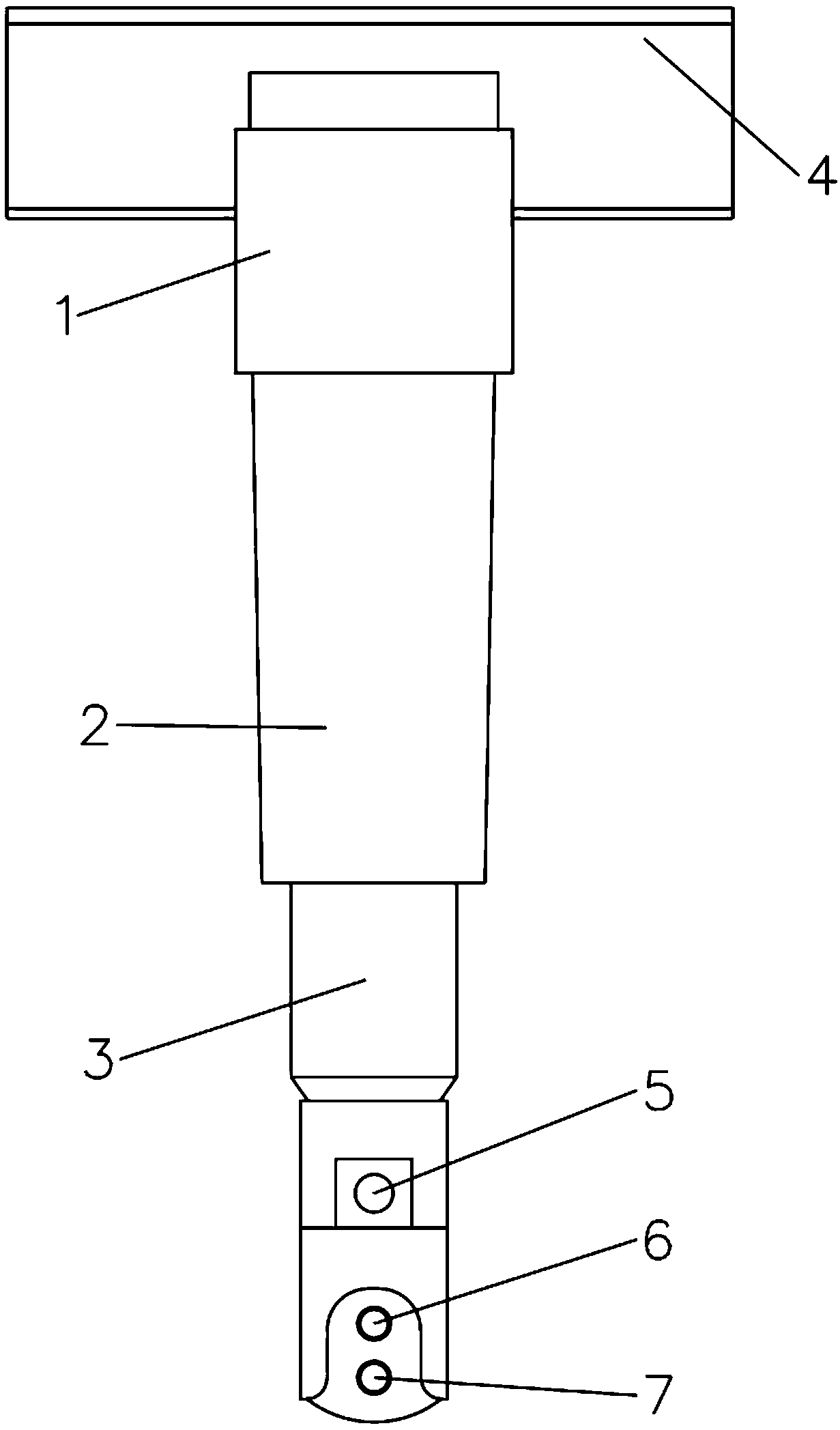

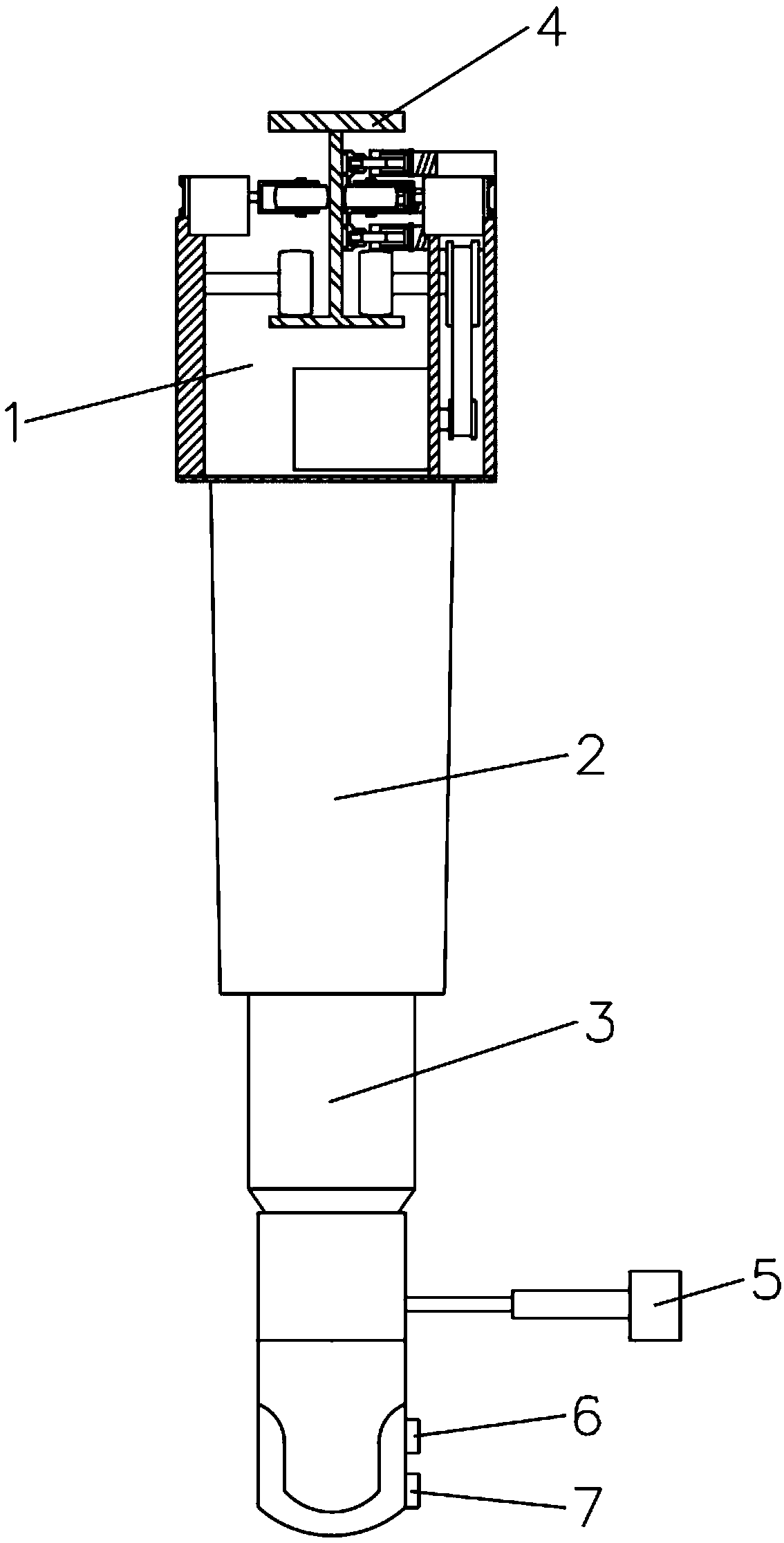

[0035] Such as figure 1 As shown, an intelligent partial discharge inspection robot includes a partial discharge inspection robot, a track 4 and a background host 41. The partial discharge inspection robot is slidably connected to the track 4, and a sliding contact line 21 is provided on the track 4. The partial discharge The inspection robot is equipped with a collector 22 and a power conversion module 51. The collector 22 is in sliding contact with the trolley line 21. The power conversion module 51 is used to convert AC power into low-voltage direct current to supply power for the partial discharge inspection robot. The robot is provided with a partial discharge detection assembly 5, a controller 46 and a data collector 47, the partial discharge detection assembly 5 collects partial discharge data, the controller 46 controls the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com